00:00

The founders of RigStrips set out to solve a simple but universal problem for skiers and snowboarders: how to lean expensive equipment against the car while loading and unloading without scratching the paint or watching it all inevitably fall to the ground. Born in the Rockies and tested on the hill, they designed and produced a magnetic strip that attaches to vehicles and holds skis and boards upright.

Since a successful appearance on “Shark Tank” in 2024, RigStrips has launched a full lineup of problem-solving products for rigs around the world. But rapid growth, shifting vehicle materials, and customer feedback soon forced the team to rethink their original design without having to start over.

Rather than compromise on ease of use or durability, they saw an opportunity to rethink the product without needing to start from scratch. PTC’s cloud-native Onshape was the right fit for navigating these evolving product needs by allowing their small, distributed team to iterate quickly, collaborate visually, and bring manufacturers into the process earlier.

Adapting Product Design to Market Shifts and Consumer Feedback

RigStrips’ original magnetic product works perfectly for most vehicles. But many of today’s new cars coming to the market are constructed with non-magnetic aluminum bodies, making the original SnoStrip™ less universal. Customers also began reporting issues with product theft.

“Cars are becoming less magnetic, and people were telling us their strips were getting swiped right off their vehicles,” explains co-founder Steven Graf. “We knew we needed a new approach.”

The team explored adhesive solutions, but those were permanent and unpopular with customers. Suction cups were promising, since they are removable and work on any vehicle, but anyone could pull them off just as easily as the owner.

The challenge was clear: Design a removable suction-based product that can’t be stolen. The answer? A new mechanical locking mechanism and a faster, more collaborative way to design it.

Enabling Pre-Prototype Design Visibility with Assemblies

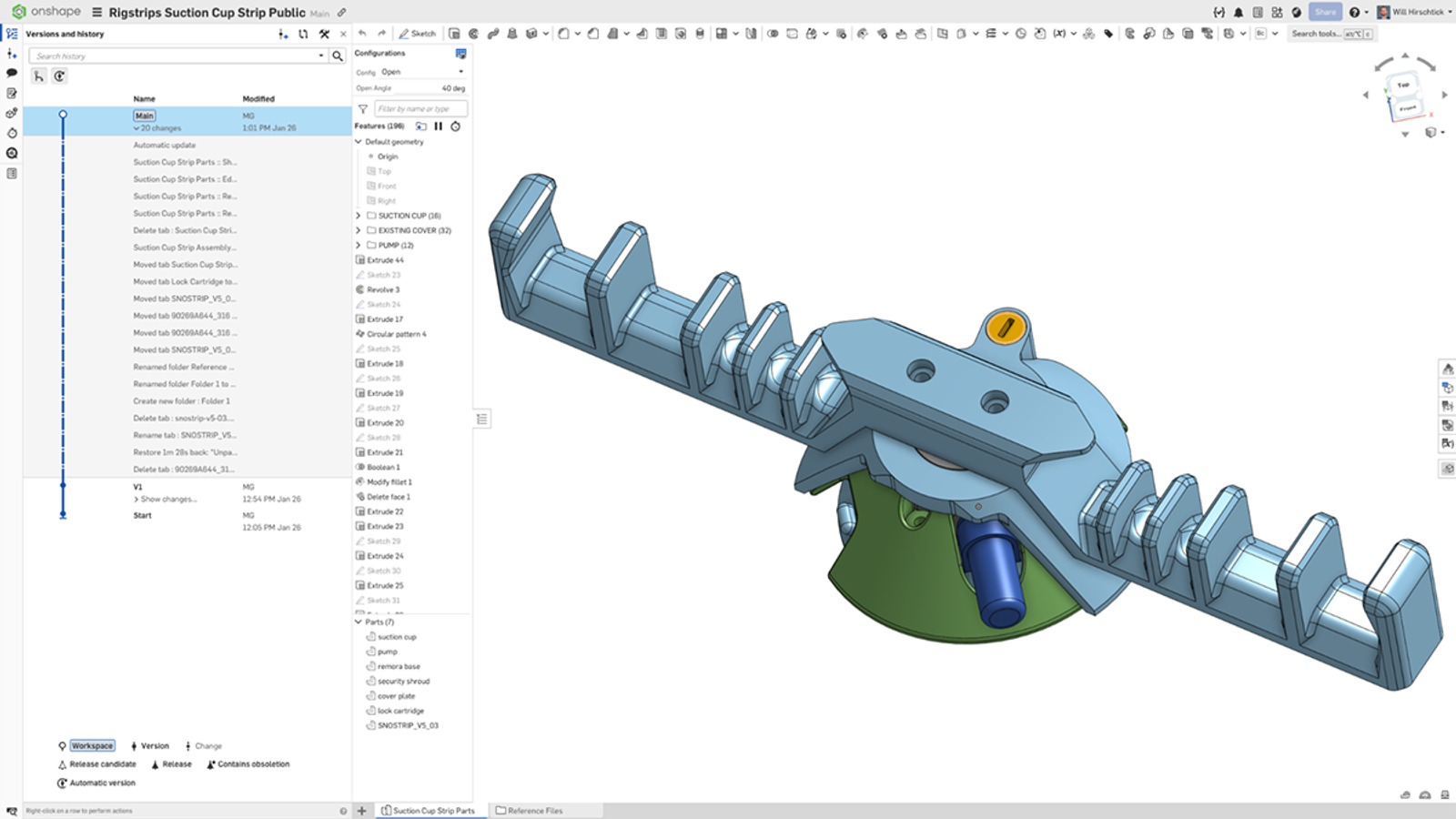

The new theft-resistant design hinged on a novel locking mechanism that prevents the suction cup from being physically released from the car when engaged, making it nearly impossible to remove without the key. The mechanism had to function reliably while feeling intuitive to users.

Using Onshape assemblies, the team could simulate how parts moved relative to one another, well before physical prototypes arrived.

“As a non-engineer, being able to see how the parts actually moved made a big difference,” co-founder Zhach Pham says. “This was the most complex product we'd designed to date, and working through the mechanism visually meant development wasn't abstract anymore. We could understand the experience from a user’s perspective.”

This early visibility helped the team identify interference issues, refine ergonomics, and iterate on usability long before committing to tooling. This allowed the team to make confident design decisions before spending money on tooling or prototypes.

Simplifying Global Product Development Collaboration

RigStrips’ product development team was distributed from the start. Graf and Pham were based in different U.S. cities, with mechanical design support coming from San Diego. Their manufacturing partners are located in mainland China and Hong Kong.

Traditional CAD workflows would have made collaboration between these locations painful. Files would be passed back and forth, and screenshots emailed with endless explanations of what changed and where. Instead, the team designed the entire new assembly in Onshape.

“Being able to share a CAD model with a link that was always up to date was huge for us,” says Pham. “Instead of trying to describe a part over text, we could all open the same model, rotate it, zoom in, and talk about the exact feature we were looking at.”

Because Onshape’s integrated CAD and PDM run entirely in a web browser, RigStrips didn’t need to worry about matching CAD licenses, installing software, or managing file versions. Anyone, from founders to manufacturers, could access the latest design instantly.

Iterating Faster With Built-In Data Management Tools

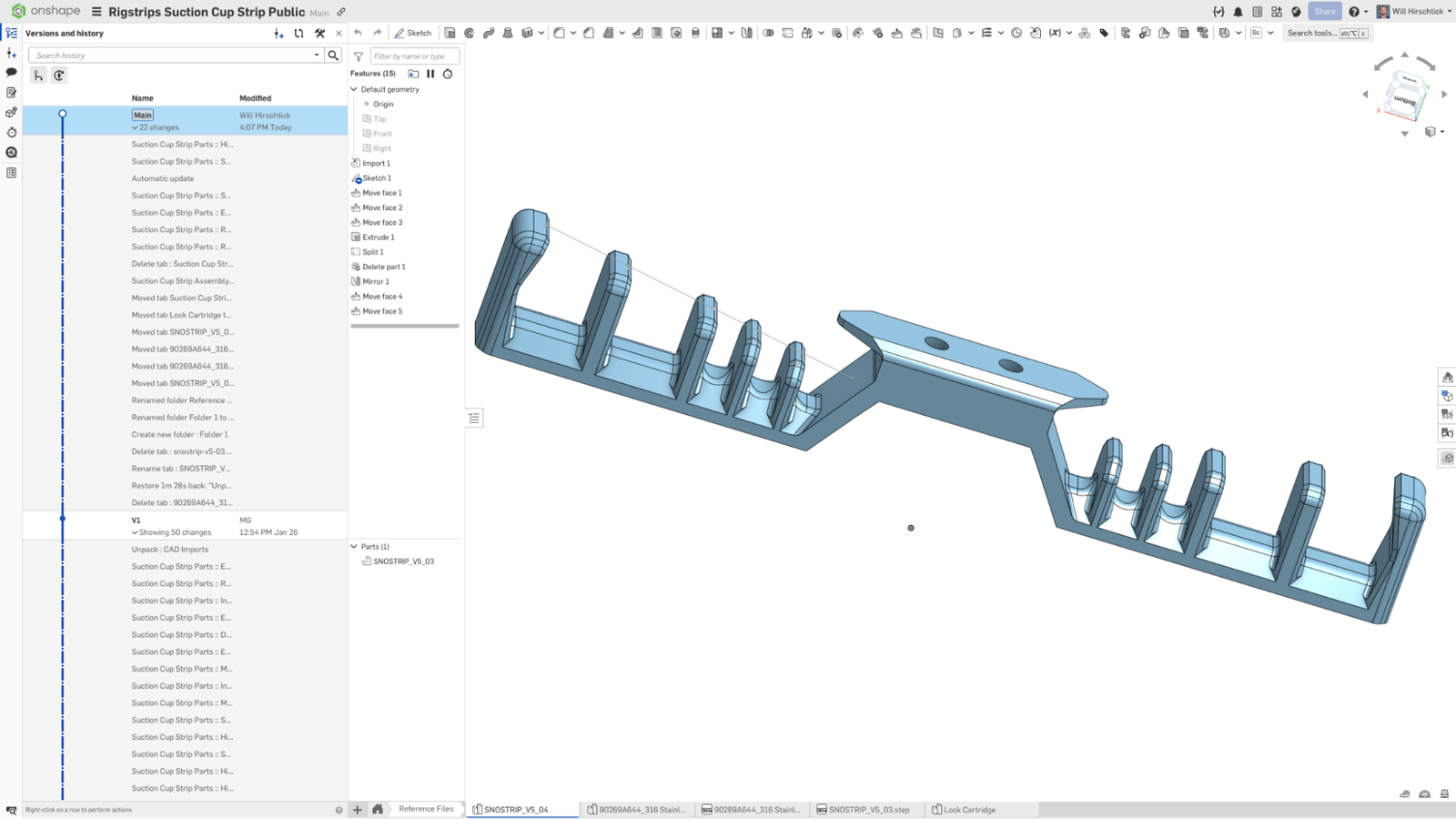

Over roughly two to three months, RigStrips went through multiple design iterations, adjusting materials, refining the locking chamber, and optimizing the housing for manufacturing.

Onshape’s built-in branching and PDM tools like versioning made it easy to explore alternative concepts without duplicating files or losing track of progress.

“When we wanted to explore more aggressive design alternatives, branching let us try things quickly without worrying about file management,” says Nick Sondej, who supported mechanical design. “You always know where the main design is, and then you can experiment freely in a sandbox that has clear traceability to where it diverted from the primary model.”

Direct editing and surfacing tools further accelerated iteration, allowing geometry to be reshaped quickly without rebuilding entire feature trees.

Bringing Manufacturers Into the Design Process

Rather than waiting for final STEP files, RigStrips invited their manufacturing partners into the design process early by sharing live Onshape models during review calls.

“We’d jump on calls and show cross-sections live,” Graf explains. “They could move components themselves and really understand how the mechanism worked.”

This early access helped manufacturers apply their own expertise sooner, streamlining design-for-manufacturing feedback and reducing surprises later in the process. The result was a smoother handoff and faster ramp to production.

Building What’s Next From Concept to Market

Thanks in large part to Onshape’s cloud-native, collaboration-first approach to product design, developing the new locking suction cup took the team about eight months from initial ideation to shipping product to customers.

“For a product like this, that timeline is incredibly short,” says Sondej. “And a lot of that comes down to not fighting your CAD tools. Onshape helps you move fast.”

For RigStrips, cloud-native Onshape wasn’t just a design tool. It was the connective tissue between ideas, people, and production. By removing outdated barriers to collaboration and iteration, Onshape helped the brand respond to market changes with speed and confidence.

And as RigStrips continues to expand its product line, the same cloud-based workflows will help ensure their next idea moves just as fast.

Il programma Onshape Discovery

Scopri come professionisti CAD qualificati possono ottenere Onshape Professional per un massimo di 6 mesi, senza alcun costo!

Latest Content

- Caso di studio

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 Ulteriori informazioni

- Blog

- Evaluating Onshape

- Collaborazione

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 Ulteriori informazioni

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 Ulteriori informazioni

- Blog

- Evaluating Onshape

- formazione

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 Ulteriori informazioni