Die Herausforderung

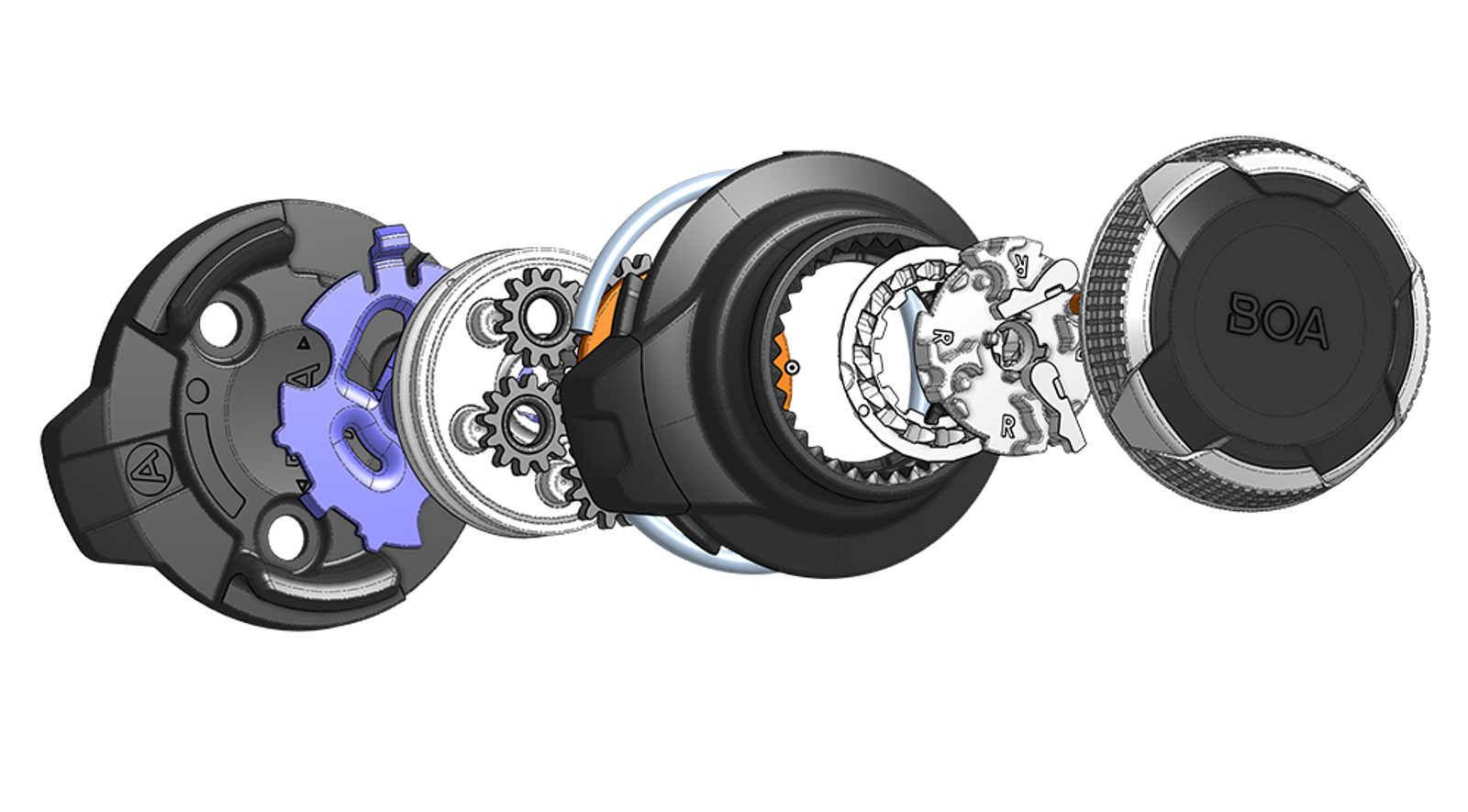

The BOA® Fit System, created by BOA Technology, is trusted equally by world-class athletes and industrial workers alike. Combining micro-adjustable dials, lightweight yet durable laces, and low-friction guides, the system delivers a precision fit that enhances speed, stability, agility, and energy transfer across footwear, helmets, braces, and work gear.

BOA’s Denver-based product development team designs each component, then works closely with global brand partners to integrate the product into their specific sport, industry, or use case. As these partnerships expanded, so did the needs and complexity of BOA’s design process. Designers needed to collaborate in real-time, often in parallel with manufacturing and brand partners. Managing collaboration between crash-prone legacy CAD systems, conflicting and outdated file versions, and inconsistent workflows created bottlenecks that slowed product development and design iteration times while introducing data security risks.

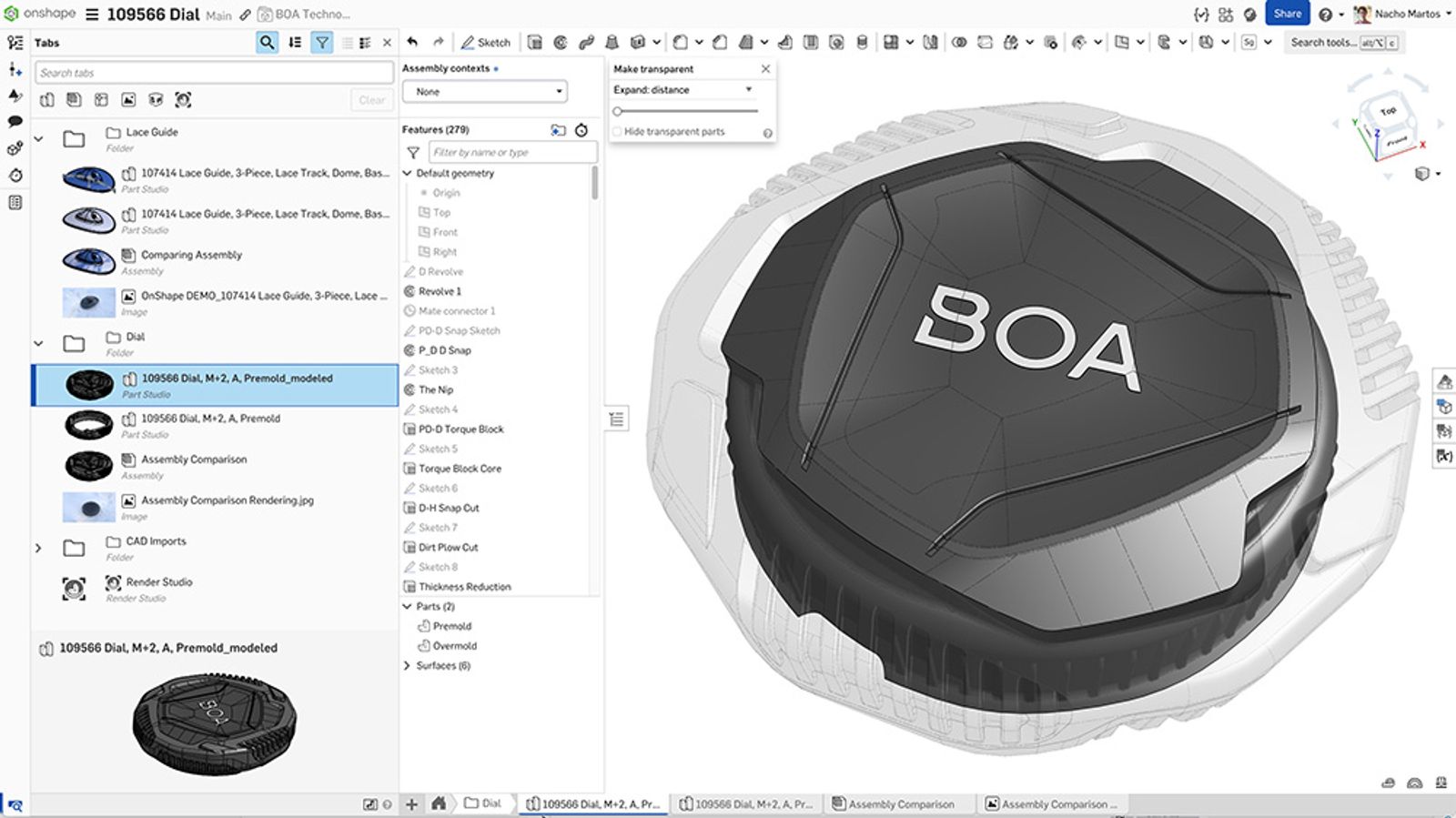

BOA turned to PTC’s Onshape, a cloud-native CAD & PDM system that supports their need for rapid iteration, rigorous testing, and seamless global collaboration. Onshape ensures BOA’s teams and partners always work from the same single source of truth, eliminating versioning conflicts, maintaining data integrity, and ensuring the performance and reliability their products demand.

Results

- 25% increase in engineering productivity by eliminating crashes, IT overhead, and manual file management

- Faster product cycles with real-time collaboration and parallel design work

- Empowered design experimentation with branching and merging, accelerating innovation while minimizing risk

- 24/7 alignment with global stakeholders thanks to Onshape’s single source of truth

Seeing three engineers co-editing the same model in real-time was mind-blowing. That’s when we knew Onshape would transform the way we work.’’

Eliminating Legacy CAD & PDM Headaches to Improve Engineering Output

Before Onshape, BOA’s legacy SOLIDWORKS CAD and PDM system struggled to keep pace with their expanding product lines and partnerships. Engineers were frequently blocked by file check-in/check-out bottlenecks, version conflicts, and slow review cycles. Crashes wiped out hours of work, and logging into PDM through a VPN created friction that often slowed ideas before they even reached CAD.

“We’d lose hours in a week just dealing with crashes, file management, and the limitations of PDM,” recalls Clay Corbett, BOA’s Director of Engineering. “You can’t always recreate your thought process after a crash. If that design path is gone, you might not figure it out again.”

Switching to cloud-native Onshape with built-in PDM has transformed BOA’s engineering workflow. Today, design updates sync instantly across global teams, no more check-ins, file conflicts, or VPN delays. Engineers can collaborate in real time, confidently exploring ideas without fear of lost work or system crashes.

“The difference is night and day,” says Corbett. “Now we can focus on solving problems instead of managing files. Everyone’s working from the same source of truth, and that has a huge impact on how fast we move.”

By removing the friction of file-based tools, BOA’s engineering team reports at least a 25% increase in productivity, along with faster review cycles and higher design confidence. What once required hours of coordination now happens seamlessly in the cloud, freeing engineers to spend more time innovating and less time troubleshooting.

“With Onshape, I can open a Part Studio, start modeling, and not think about file names or folders,” says Tyler Ziebelman, Senior Design Engineer. “It’s freed me up to just get ideas down before they disappear.”

Real-Time Collaboration Accelerates BOA’s Innovation

In the past, collaboration at BOA was a relay race; one engineer had to finish working on a design before another could begin. Onshape’s branching and merging capabilities replaced BOA’s old “save-as” workflow with a structured, traceable process where designers can experiment with different ideas in parallel, then merge the best options back into the main design. Engineers can explore design variations without fear of disrupting or overwriting each other’s work.

“Seeing three engineers co-editing the same model in real-time was mind-blowing,” says Corbett. “That’s when we knew Onshape would transform the way we work.”

For BOA’s engineers and designers, Onshape has opened up a whole new frontier for rapid experimentation.

“The biggest benefit between Onshape and legacy CAD is the ability to be fearless,” says Ziebelman. “I can generate multiple concepts at once and quickly jump back and forth, all in one document.”

This agility enables faster iteration, more transparent collaboration, and a higher likelihood of finding the optimal solution earlier in the process.

“On a recent project, we went from what normally would have been a one- to two-week iteration cycle down to two or three days,” explains Ziebelman. “Having options side-by-side in one document lets us move quickly to the right solution.”

Streamlining Feedback Across Global Teams and Partners

With teams and partners spanning the U.S., Austria, Japan, and beyond, BOA relies on Onshape to keep everyone aligned. Every engineer, test lab, and manufacturing partner can see the latest design changes instantly, no emailing STEP files or syncing across systems.

“Anyone can log in and see the current state of development,” says Corbett. “That’s a big shift from when CAD was locked down to just the project team.”

That access extends to external brand partners like K2, Ariat, The North Face, New Balance, and more. Onshape users can log in from any internet-connected device, no installs or workstations required, to review IP-safe CAD variations securely.

“Instead of sending someone to hunt for a file, I just copy a version link from the tree and paste it in chat,” says Ziebelman. “They’re looking at exactly what I want them to see.”

More Than CAD: Onshape as BOA’s Innovation Partner

For BOA, Onshape is more than a CAD replacement; it’s a trusted partner in their innovation.

“We work with brands around the world to co-develop products, so when we saw Onshape operating in the same way with us, it was a natural fit,” says Corbett.

Unlike on-prem CAD providers where feature requests or bug reports often vanish without a trace, BOA has found Onshape’s team highly responsive to suggestions and requests.

“Every time we’ve looked to expand how we use Onshape, their team has been there to talk through strategies, suggest rollout approaches, even connect us with companies who’ve done something similar,” says Corbett. “That level of responsiveness isn’t industry standard, and it’s been critical for our adoption.”

This shared, agile collaboration style has given the team not just increased confidence in the platform, but also more confidence in their design evolution.

“Onshape has really opened up my confidence in CAD,” says Ziebelman. “I can try new surfacing techniques, branch off quick ideas, and use the compare tool to make sure only the right changes go into a release. That’s powerful.”

As BOA expands into new industries and performance applications, Onshape remains a trusted partner driving faster, more responsive, and sustainable innovation.

“Onshape helps us move faster, be more responsive, and develop more innovative products that meet rising sustainability demands,” says Corbett. “That inspires a lot of confidence in where we can go as a company.”