Die Herausforderung

K2 Skis has been at the forefront of ski design and innovation for more than six decades. Founded in 1962 and headquartered in Seattle, the company is known for combining performance, creativity, and cutting-edge technology to create world-class winter sports equipment used by professional athletes and weekend adventurers alike.

With traditional desktop CAD and disconnected product data management (PDM), K2 was facing an increasingly slow and fragmented product development process. The team struggled with time-consuming design workflows, inefficient communication with global manufacturing partners, and manual file management that led to confusion and delays.

"We needed a better solution and a faster way to iterate," says Jed Yeiser, R&D Engineer at K2 Skis. "Our previous setup just wasn't keeping pace with how quickly we wanted to move." That’s when they turned to Onshape for a modern, cloud-native CAD and PDM solution.

Results

- Reduced design time by 20-25%, improving time-to-market

- Streamlined communication across global teams with real-time collaboration

- Enabled designers to move faster and innovate confidently with customized automation workflows

- Automated CAD file management with built-in PDM, reducing design errors and reliance on IT staff

We wouldn’t have been able to develop some of our latest ski technologies without Onshape. It allows us to move faster and innovate with confidence.’’

Accelerating design cycles up to 25% with faster modeling, reviewing, and prototyping

Before moving to Onshape, K2’s design team relied on SOLIDWORKS, which required time-consuming manual file management and complicated processes for sharing and reviewing designs. The limitations of SOLIDWORKS became increasingly clear as the team sought faster ways to bring new products to market while maintaining design quality.

Onshape provided a fresh approach with its cloud-native platform, allowing the team to consolidate design and data management in one place. The transition, initially motivated by the need for better PDM, quickly proved to have far-reaching benefits beyond file management.

"We came to Onshape for the PDM," says Yeiser, "But we stayed, and will stay, for everything else."

With Onshape, K2 has cut design and prototyping time by an estimated 25%. The team can quickly model, review, and update designs, helping them meet aggressive development timelines and deliver new products to market faster. This speed has been crucial for staying competitive in an industry where trends and consumer demands evolve rapidly.

"When we made the switch, I was forecasting a 20% time savings, and I think we're closer to 25%," says Yeiser. "The PDM was the largest contributor to that improvement, but it's also the overall speed of the system that makes a huge difference."

"The speed and efficiency with which we can get designs into a complete package is a game-changer," Yeiser adds. "Our engineers literally say, 'I love Onshape' while working."

Onshape’s intuitive workflows like keystroke-driven sketch constraints also help the team move faster with fewer clicks and less frustration. Engineers no longer waste time on cumbersome workarounds and can instead focus on creative problem-solving and design refinement.

Enabling global collaboration to innovate more quickly with confidence

K2’s design and manufacturing teams are spread across Seattle, China, and parts of Europe, but with Onshape, real-time collaboration keeps designs moving forward. Everyone accesses the same up-to-date models without manual file sharing, enabling faster decision-making and clearer communication.

"We can send a link to the factory, have them review the design, and know everyone’s looking at the exact same model," says Yeiser. "It streamlined everything."

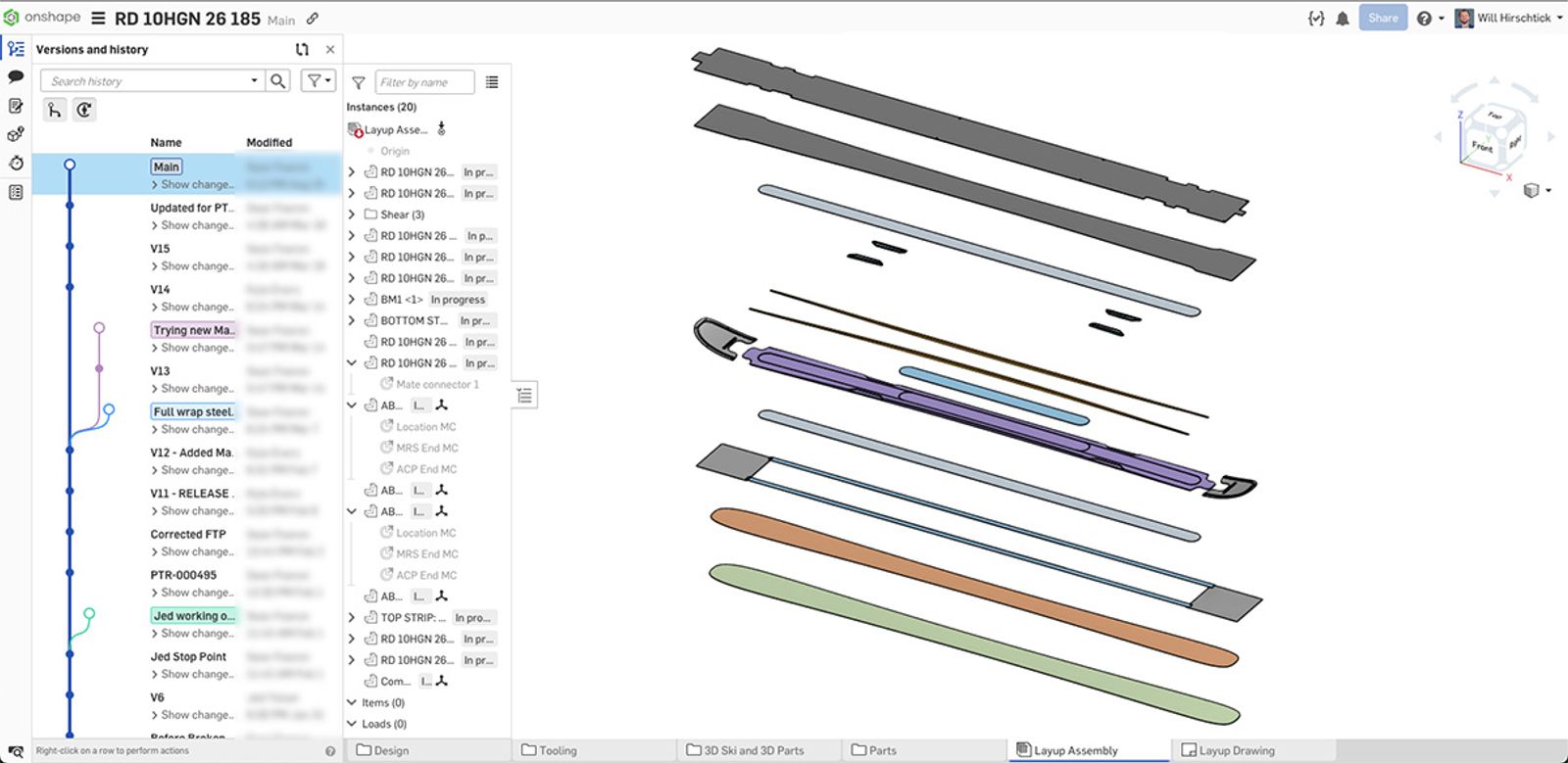

With built-in commenting and version control, K2 ensures that every stakeholder stays aligned, speeding up design reviews and eliminating delays caused by conflicting versions or miscommunication. The team encourages manufacturing partners to suggest design changes and leave comments directly in Onshape, creating a more collaborative feedback loop.

Instead of relying on screenshots, PDFs, or email chains, suppliers can highlight issues, suggest changes, and leave notes all within the native Onshape model. This real-time input reduces turnaround times, prevents costly misunderstandings, and allows K2 to resolve manufacturability concerns before they become production issues.

“The fact that our suppliers can open a link and immediately be in the right model is a huge deal,” says Yeiser. “It keeps us all on the same page, saves days of back-and-forth, and makes the whole process much smoother.”

With Onshape’s branching and merging capabilities, K2 engineers have the flexibility to explore new ideas without the risk of losing work or disrupting others. This has been instrumental in the development of K2’s most advanced ski technologies to date.

Simplifying existing workflows with customized automation

The team has also created custom automations using Onshape’s FeatureScript programming language to streamline repetitive tasks and save valuable engineering time. According to Yeiser, FeatureScript has played a critical role in K2’s time savings — more than many outside users may realize.

"With a few lines of code, we were able to drastically reduce the amount of time it takes us to import designs from our analysis tool, streamline creating QC documentation for parts (the FeatureScript analyzes a body and spits out a table of QC points), and automate many of our 'standard' processes," Yeiser says.

"Yes, you need to write code to leverage FeatureScript, but it's hard to imagine that there are industries out there that wouldn't massively benefit from some customized solutions," he adds.

With these FeatureScripts, tasks that once required dozens of manual steps are now handled with a single click.

"We wouldn’t have been able to develop some of our latest ski technologies without Onshape," Yeiser says. "It allows us to move faster and innovate with confidence."

With the ability to prototype multiple design directions in parallel, K2 is able to test new concepts earlier and make data-driven design choices that lead to better products.

Eliminating design file chaos with built-in PDM

Onshape’s built-in PDM eliminates the manual file management that used to slow K2’s design process. Instead of juggling formats and servers, the team works in a single, secure environment with the latest data always accessible.

Before Onshape, K2 manually managed files using naming conventions and folder structures. Engineers would check a file out, make changes, check it back in, and hope no one else had made a conflicting update in the meantime.

“It was slow, it was clunky, and it wasn’t really designed for the kind of iterative collaboration we wanted to do,” Yeiser says.

With Onshape, PDM is no longer a separate process. Every change is tracked automatically, version control is instant, and the whole team can work together in the same space without fear of overwriting or losing progress.

“PDM used to be a huge focus for us, but now it's just done automatically,” Yeiser says. “We don't even think about it anymore.”

Yeiser points out that this shift didn’t just eliminate technical barriers; it changed how the team thinks about design collaboration.

“In file-based systems, you're always cautious,” he says. “You’re waiting for someone to check something in or worrying if the version you're looking at is the right one. That friction slows everyone down. Onshape removes that entirely.”

Because there are no files to manage, there’s also no delay between design and decision-making. The most current data is always accessible to anyone who needs it — whether they’re down the hall or on the other side of the world. That immediacy has helped K2 move faster, make smarter decisions, and eliminate the costly mistakes that used to come from version mismatches or outdated references.

By moving away from a patchwork of disconnected CAD and PDM tools, K2 has also reduced its reliance on IT support and eliminated many of the manual steps that previously slowed down the release process. Product changes can now be implemented, reviewed, and approved faster, without compromising data integrity or design accuracy.

Learn more about how Onshape allowed K2 to rethink PDM for speed and security:

Driving product innovation with data-driven design

With Onshape, K2 is not only delivering products faster today but also laying the groundwork for smarter design in the future. The team is exploring API development to connect real-time mechanical analysis directly to their Onshape models, aiming for a fully integrated digital design environment. By linking analysis directly to Onshape, geometry and performance data stay connected, giving engineers immediate feedback as they design.

“This would mean we’re not just designing shapes and then checking if they’ll hold up,” says Yeiser. “We’d be designing with performance built in from the start. It lets us catch problems earlier, iterate faster, and ultimately deliver higher-performing skis to market.”