03:59

Understanding how different team members approach CAD modeling can transform your engineering workflow. Using Onshape Analytics, research from the University of Toronto’s Ready Lab has identified distinct collaboration patterns that reveal why some teams design more efficiently than others.

Professor Alison Olechowski, who leads the Ready Lab, studies how engineering design teams work together to create better products. Her research uses CAD analytics to push the frontiers of designer expertise and collaboration, ultimately helping teams work smarter and tackle design complexities more effectively.

Note: Only Enterprise and Education Enterprise plans offer Onshape Analytics.

Why CAD Analytics Matter for Team Performance

"Onshape is my research laboratory," explains Professor Olechowski. Unlike traditional research that requires extensive instrumentation, modern CAD platforms provide comprehensive audit trails – complete records of model changes tagged by user and time. This data reveals invaluable insights about how high-performing teams collaborate.

Companies like Avidbots, which create autonomous cleaning robots, leverage these insights to break down barriers between disciplines and fully utilize their team's diverse skills. For organizations embracing agile design methods, understanding collaboration patterns becomes crucial for streamlining workflows.

The Four CAD Personalities

Analysis of engineering teams reveals four distinct CAD collaboration styles:

The Architect

Establishes the foundational structure of models and contributes creation actions throughout the design lifecycle. Architects think systematically about how components will fit together and often set modeling standards for the team.

The Collaborator

Actively shares documents, leaves detailed comments, uses branching and merging features, and frequently manages interfaces between assemblies. Collaborators excel at keeping team members connected and aligned.

The Reviewer

Views CAD models and provides feedback through comments but typically doesn't modify geometry directly. Reviewers often represent stakeholders from manufacturing, quality, or other non-core engineering functions who provide critical input.

The Observer

Identifies and fixes issues through intermittent but precise editing actions. Observers often oversee geometric dimensioning, tolerancing, and CAD standards compliance, catching details others might miss.

How Manufacturing Experience Shapes Design Approach

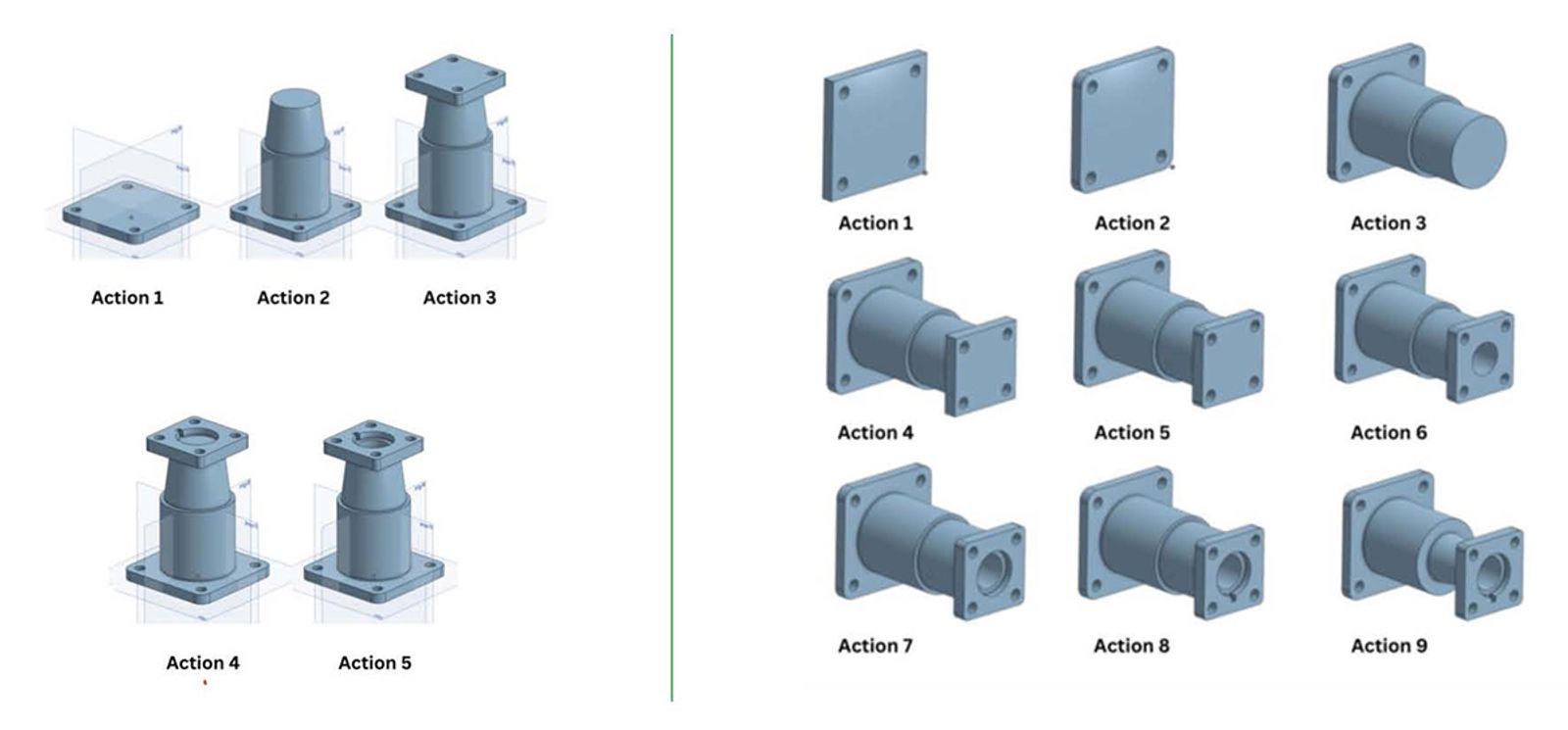

An experiment reveals fascinating connections between a designer’s background and their CAD modeling methods. Engineers familiar with 3D printing tend to build models from the top plane, mimicking how additive manufacturing creates parts layer by layer. In contrast, professionals with machining experience often model from the front plane, reflecting how parts are held in chucks during subtractive manufacturing.

These ingrained approaches highlight how past experience influences current design decisions – sometimes in ways that may not be optimal for the specific manufacturing method planned for a part.

Identifying Your Team’s Collaboration Patterns

To understand your team’s dynamics take a look at Onshape Analytics, look for these behavioral indicators:

Architects create the most features and establish folder structures Collaborators generate the most comments and branch/merge activity

Reviewers have high view-to-edit ratios and comment frequently Observers make surgical edits focused on standards and compliance

Understanding these patterns helps teams adapt workflows to leverage each member's natural strengths while identifying potential collaboration gaps.

Building Collective Intelligence

The key insight from this research isn’t just identifying personalities – it’s using this awareness to build collective intelligence about what makes design processes more effective. Teams that understand their collaboration patterns can:

- Assign tasks that match natural working styles

- Identify when certain personality types are missing from projects

- Develop training programs that help team members expand their collaborative skills

- Create workflows that accommodate different approaches to problem-solving

The Future of Data-Driven Design Collaboration

As engineering teams become more distributed and projects grow more complex, understanding collaboration patterns becomes increasingly valuable. Analytics provide objective insights that can help teams optimize their workflows, reduce design iteration cycles, and ultimately create better products.

The research from the Ready Lab demonstrates that the data generated during everyday CAD work contains powerful insights about team dynamics and design effectiveness. By becoming more aware of these patterns, engineering teams can work smarter, not just harder.

Commercialisez vos produits plus rapidement, plus efficacement et de manière plus sûre.

Latest Content

- Étude de cas

- Robotique

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 En savoir plus

- Blog

- Evaluating Onshape

- Simulation

- Rendu

- Surfaçage

- Produits de grande consommation

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 En savoir plus

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 En savoir plus

- Blog

- Becoming an Expert

- Pièces de tôlerie

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 En savoir plus