The Challenge

OpenStar Technologies, a New Zealand-based startup, is developing a new type of fusion reactor with the goal of commercializing unlimited clean energy. Once seen as purely theoretical, OpenStar is helping make fusion energy a reality using an unconventional reactor with a powerful levitating magnet at its core. This is known as the levitated dipole. Their team faced the dual challenge of designing highly complex, one-off components like superconducting magnets and vacuum chambers while rapidly iterating to stay ahead in both a competitive and technically demanding field. With team members across multiple locations around the globe and a growing engineering staff, they needed a CAD solution that enabled fast design cycles, real-time collaboration, and built-in data management from day one. They decided to go with Onshape.

Results

- Faster iteration: OpenStar rapidly designs and refines complex reactor components using PTC Onshape’s cloud-native CAD, cutting design feedback loops from days to hours.

- Seamless global collaboration: Teams collaborate in real-time across time zones with Onshape’s integrated tools, improving communication and accelerating progress.

- Streamlined data management: Built-in version control gives OpenStar full visibility into design history, enabling quick access to previous iterations and a complete project record.

- Efficient release management: Feedback is gathered within Onshape before final release, helping manufacturing plan ahead and reduce delays.

We’re trying to solve one of humanity’s most pressing challenges. It’s incredibly gratifying work. With Onshape, we’re staying agile and moving fast, because the world can’t wait for fusion.’’

Reinventing fusion energy with a revolutionary approach

Fusion — the same process that makes stars shine — is a near-limitless form of clean energy. As opposed to fission, the nuclear technology the world currently uses, fusion doesn’t produce any planet-heating pollution or long-term radioactive waste. A key milestone for tackling the escalating climate crisis, fusion is able to use existing grid infrastructure, offering a climate solution that involves little change to the world as it is now.

OpenStar Technologies is aiming to make fusion energy a commercial reality using a bold, underexplored concept: the levitated dipole reactor. Drawing on early MIT research and integrating high-temperature superconducting (HTS) technologies, OpenStar is uniquely positioned as the only private company developing this inherently stable plasma configuration for practical fusion energy.

“Fusion has long been the holy grail of sustainable energy,” says Patrick Coulson, Director of Engineering Operations at OpenStar. “Our mission is to make abundant, carbon-free baseload energy real — and the levitated dipole gives us a credible pathway to get there.”

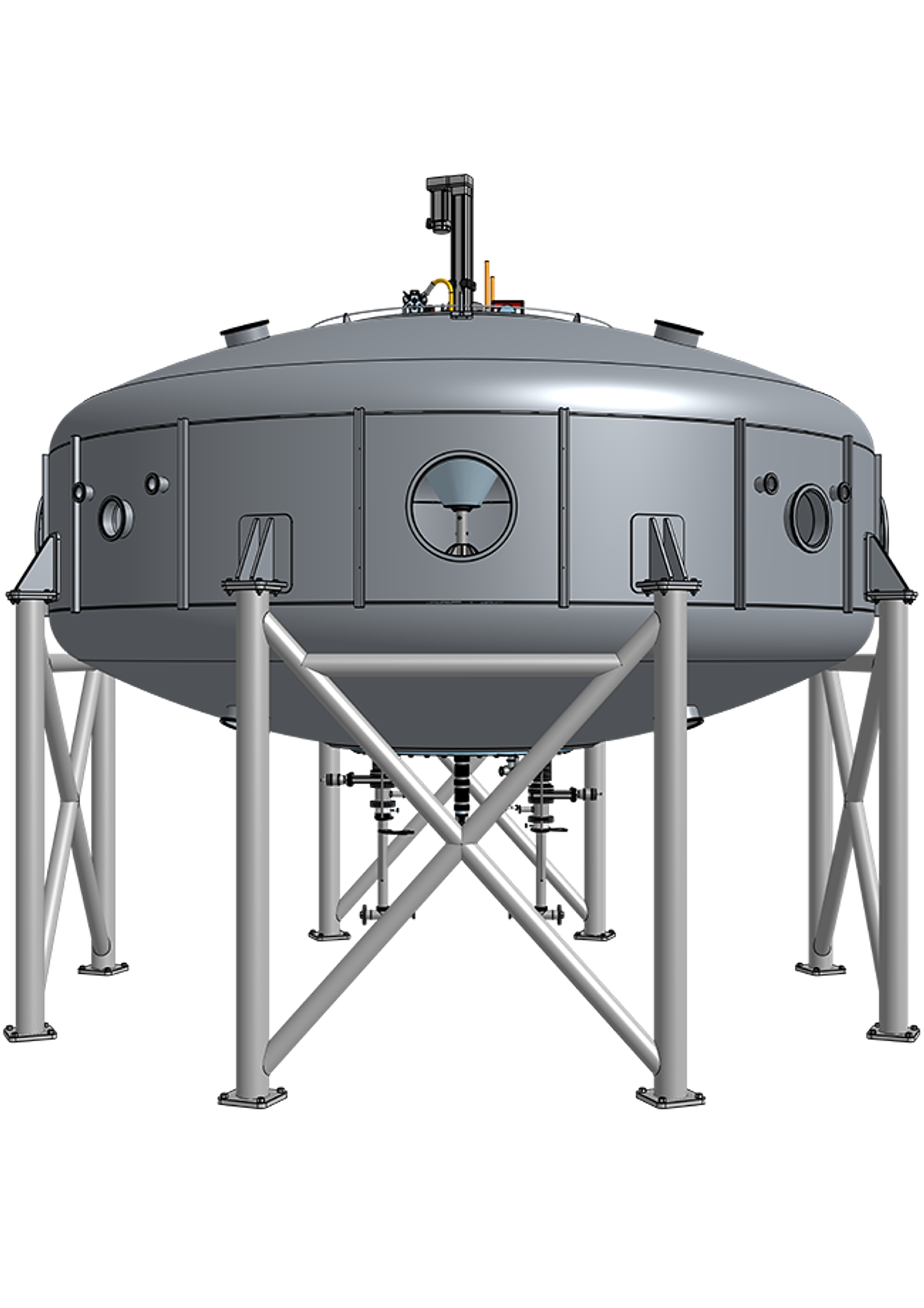

On the pathway to commercial fusion power generation, OpenStar's solution will also allow for high-impact, near-term applications. Their "Maui" class reactors, forecasted to come to market as soon as 2030, will serve as neutron sources for a diverse range of applications. These will include enabling superior unit economics for the production of medical isotopes, an urgent global need traditionally served by aging fission reactors, as well as the potential for transmuting high-level radioactive waste from the nuclear fission industry. OpenStar will be cleaning up the world and saving lives even before they reach commercial fusion power plants.

Speeding up innovation with Onshape

From its inception in 2021, OpenStar made Onshape its primary CAD platform. “We’ve always used Onshape,” Coulson explains. “It gave us the flexibility, collaboration tools, and price point we needed as a startup.”

For OpenStar, Onshape offers the right blend of flexibility, collaboration, and reliability needed to support their fast-moving, high-stakes engineering work. A cloud-native platform, Onshape eliminates the traditional pain points of file-based CAD systems like version conflicts, software crashes, and slow collaboration between sites.

With a growing, multi-location engineering team and a high volume of bespoke parts, OpenStar relies heavily on Onshape’s cloud-based access and built-in collaboration. Engineers can access and edit designs instantly from anywhere, enabling effective teamwork across continents and time zones, no installation or syncing required.

Onshape’s integrated data management and version control have been especially valuable to the OpenStar team. From organizing design iterations to managing document releases, OpenStar’s engineers are able to collaborate with clarity and confidence. Features like branching and merging allow for isolated experimentation without interfering with production work, while release workflows keep manufacturing teams aligned and ready to act the moment a design is approved.

“When a design is ready for review, our manufacturing team is notified instantly,” says Coulson. “They can begin planning or provide feedback right in the platform before the drawings are even released. It shortens the entire feedback loop.”

From powerful mate connectors to always-available version histories, Onshape has become a core enabler of OpenStar’s mission to iterate rapidly, maintain momentum, and stay focused on what matters — building the future of clean energy.

“If I were recommending Onshape to a friend, I’d say this: it just works,” says Coulson.

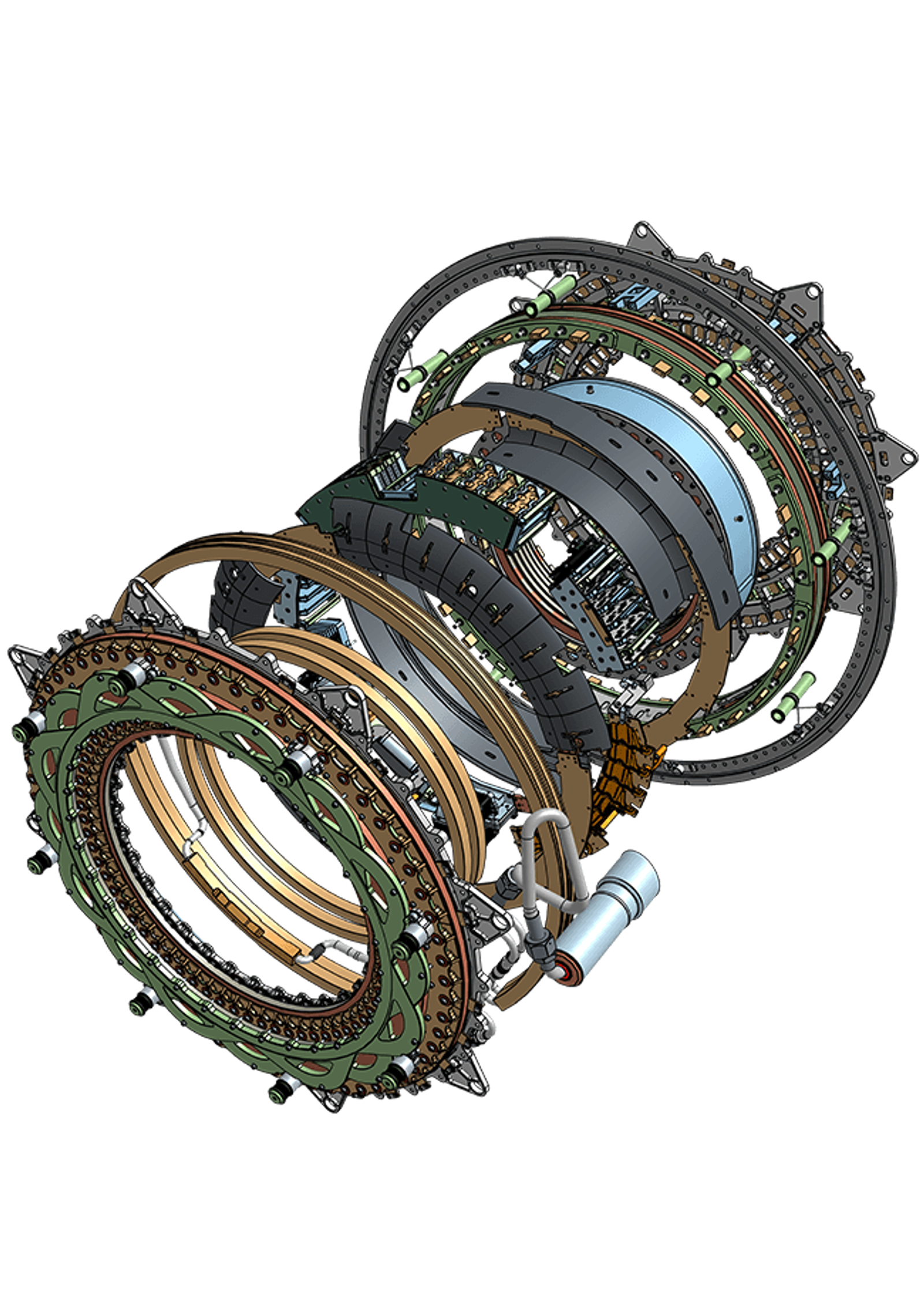

Here are some of the 1158 unique parts and complex systems OpenStar has developed in Onshape:

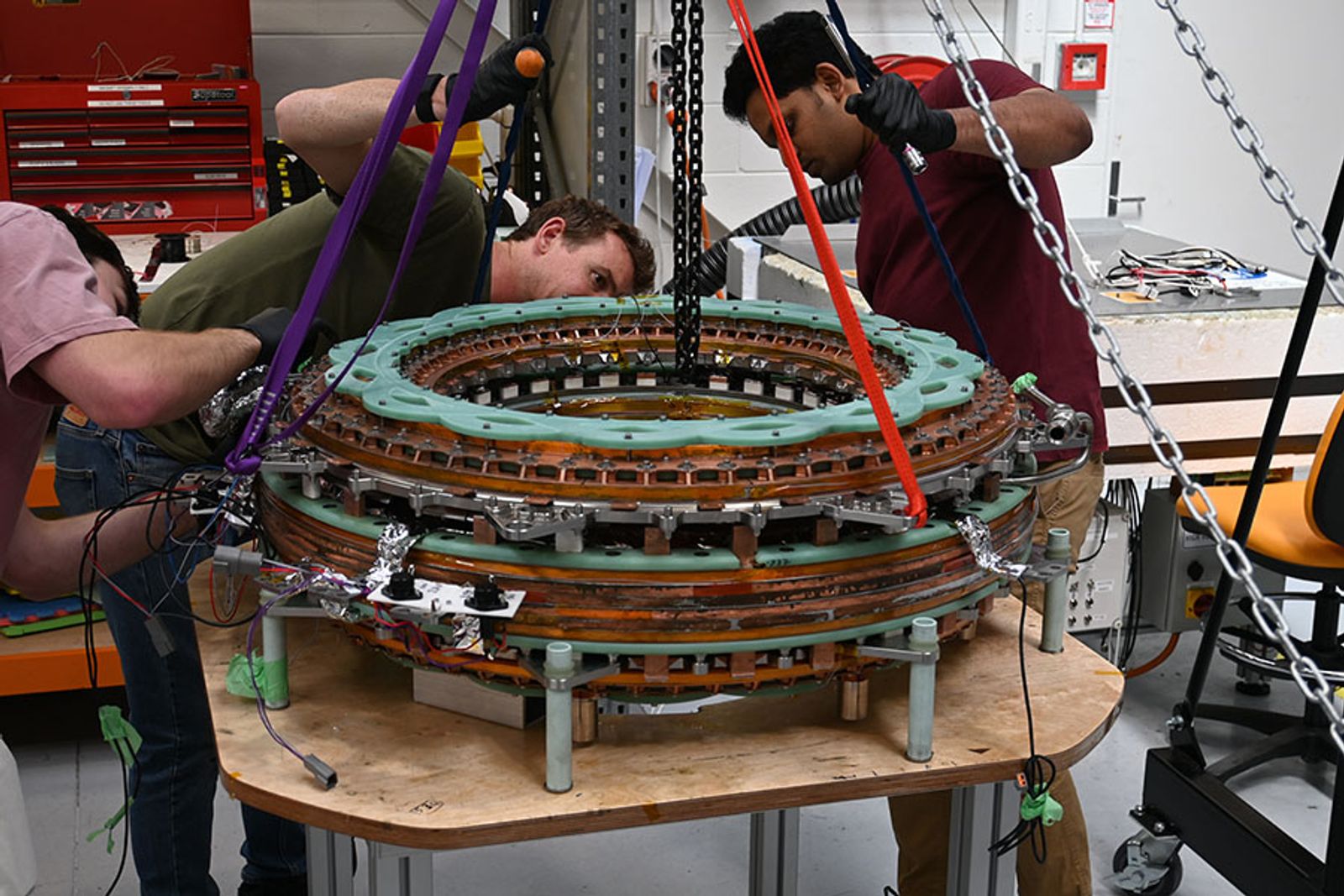

- The core magnet: A 500kg superconducting structure that reaches 5.6 Tesla and is cooled to 25 Kelvin before being levitated inside a vacuum chamber.

- 5.2m vacuum chamber: The largest structure in the project, designed to house plasma experiments in a highly controlled environment.

- Superconducting power supplies: Compact systems integrated directly into the floating magnet to maintain magnetic field strength without physical tethering.

“These are tight, constrained, high-stakes design problems,” says Coulson. “Onshape lets us collaborate and iterate fast — exactly what we need.”

A Designer’s Perspective: From Ideation to Production in Hours

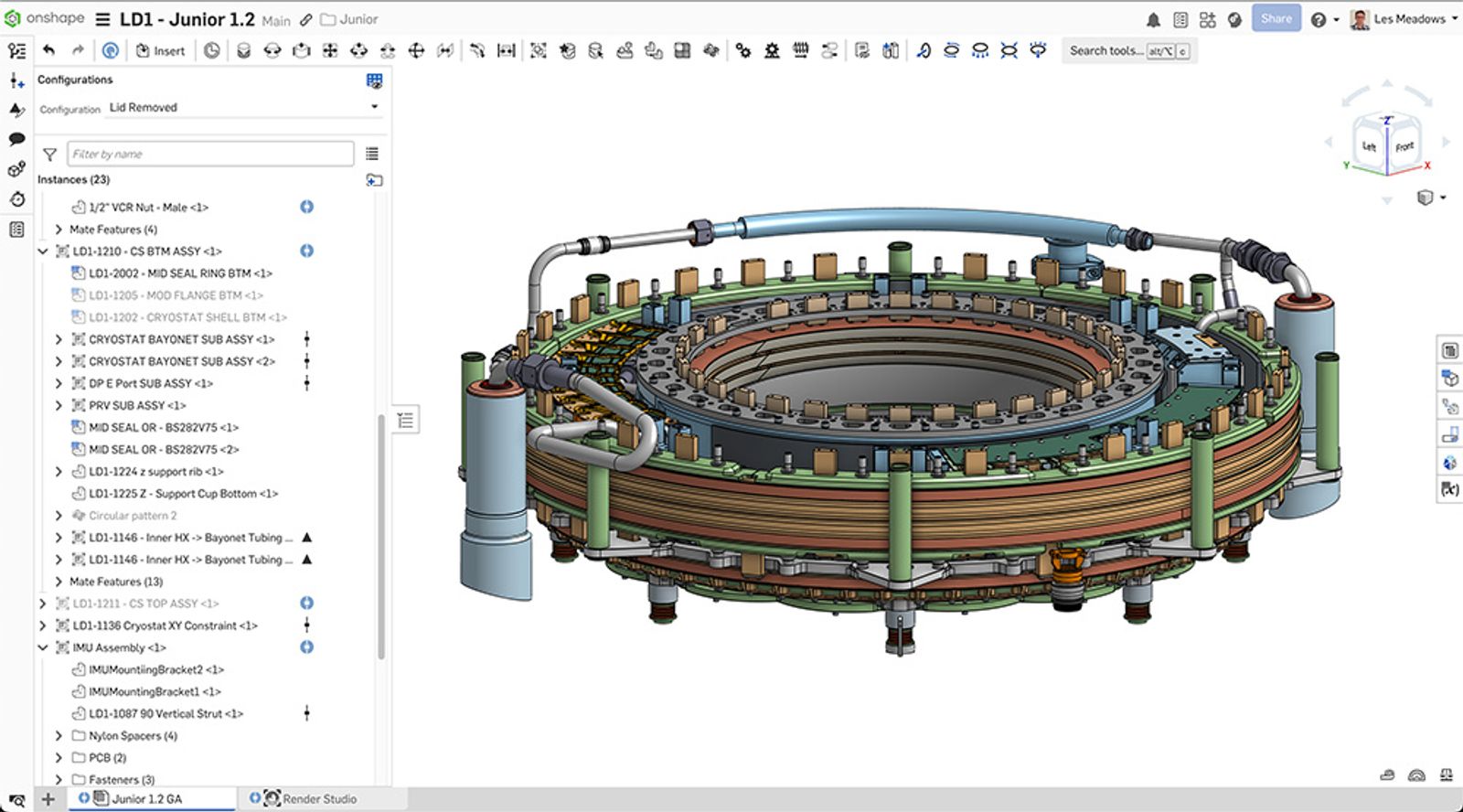

Industrial Designer Les Meadows, who led the development of OpenStar’s superconducting flux pump, emphasizes how Onshape streamlines the entire product lifecycle.

“Before OpenStar, I worked with Rhinoceros 3D, Fusion 360, and SOLIDWORKS, and faced constant frustrations with versioning, crashes, and lack of a single source of truth,” Meadows recalls. “Onshape solved all of that.”

For Meadows, Onshape’s branching and merging tools are indispensable. “We can isolate concepts, test changes, and integrate them without disrupting active workflows. It keeps experimentation fluid and risk-free.”

He also credits Onshape’s custom FeatureScript tools for extending functionality: “We’ve created our own surface tools and thread generators, which now feel native to the platform,” he explains.

From early sketches to BOM-ready production files, Onshape has allowed Meadows to reduce turnaround time “from days to hours.”

Powering the future — together

As OpenStar continues to scale its engineering team and advance toward commercial prototypes, Onshape remains central to its fast-paced development cycle.

“We’re trying to solve one of humanity’s most pressing challenges,” says Coulson. “It’s incredibly gratifying work. With Onshape, we’re staying agile and moving fast, because the world can’t wait for fusion."