05:23

Historically, software development has thrived on a “move fast and break things” approach, with quick fixes that are inherently cheaper to deploy. Hardware, however, faces high failure costs; flaws in physical products can demand expensive interventions. Constrained by physical testing (virtual and/or real), hardware development has been inherently slower with a more risk-averse culture, contrasting sharply with software’s “fail fast” mentality.

However, market expectations have fundamentally shifted, and so has the very nature of hardware design itself, which now incorporates significantly more embedded software systems. Hardware companies are now compelled to adopt the iterative agility of software firms.

With product lifecycles rapidly shrinking and a growing demand for continuous customization in industrial equipment, the traditional “waterfall” approach—aiming for a single, perfect launch—is no longer a safe method. Instead, it has become a major competitive liability.

The primary constraint on modern hardware companies is no longer manufacturing or the supply chain. The bottleneck is upstream: Design Velocity.

Today, your Design Velocity is directly proportional to your Business Velocity and is dictated by the software used by your team.

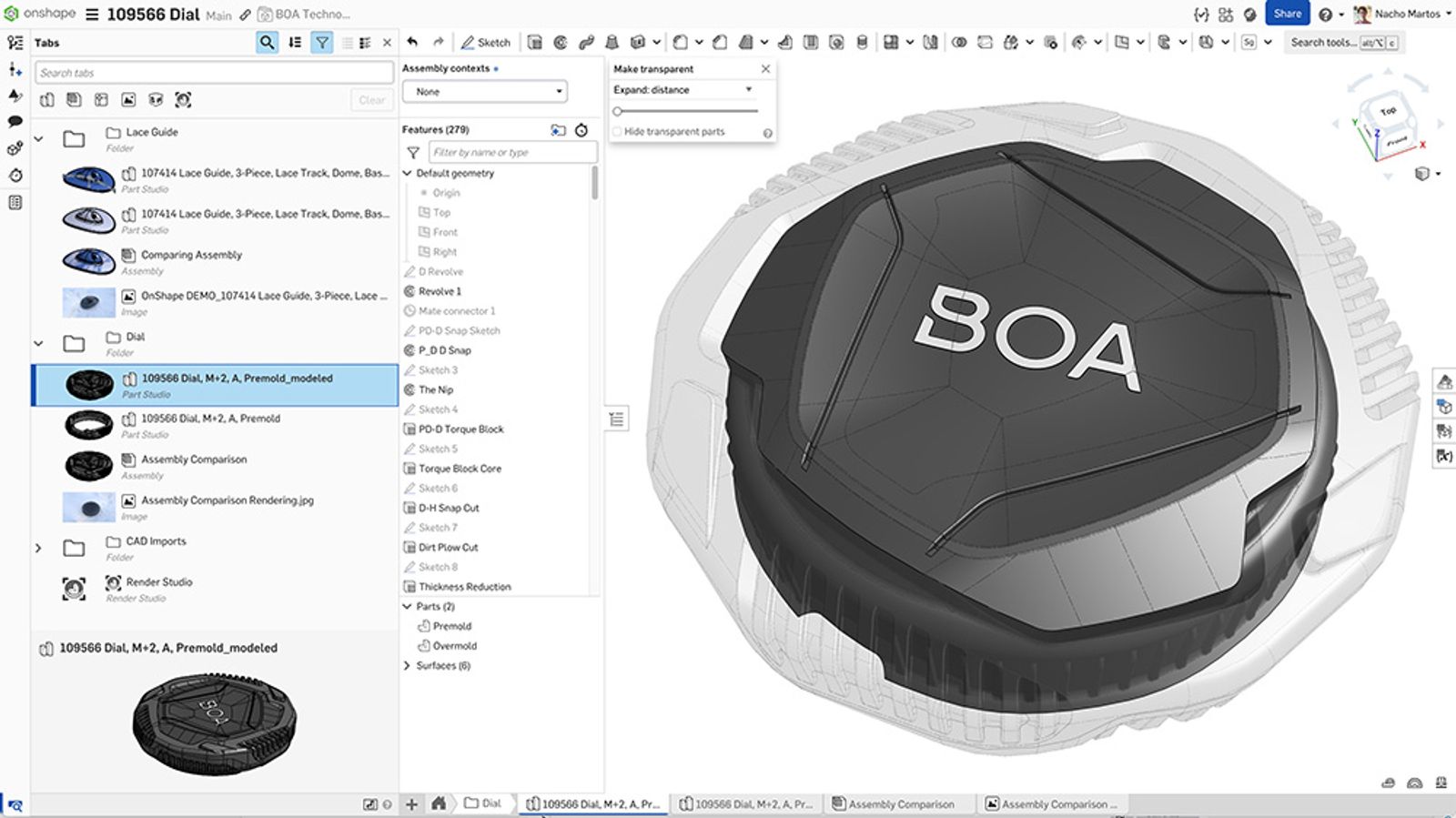

A 25% increase in engineering productivity at BOA Technology after switching to Onshape. Read the case study.

Defining Design Velocity (It’s Not Just Mouse Clicks)

How fast can this CAD user model a complex part? How quickly can we generate a drawing view?

While individual proficiency is important, it is a micro-optimization. Saving 10 seconds on a sketch is meaningless if that file sits in a PDM vault for three days waiting for approval.

Real Design Velocity is not measured in mouse clicks. It is measured in Cycles of Learning. It is the total time it takes to travel the loop:

- Concept

- Prototype

- Test or Simulation

- Design Change

The faster you spin this flywheel, the faster you stabilize the product. The companies winning in the market today aren’t necessarily the ones with the “genius” initial idea. They are the companies that can iterate an idea 50 times in the same span it takes their competitor to iterate 5 times.

The variable that kills Design Velocity is rarely the geometry creation itself. The variable is the “Wait Time.” It is the empty space between value-added tasks. It’s waiting for a large assembly to load over a VPN. It’s waiting for a file to be checked back in by a colleague. It’s waiting for IT to install the latest service pack so you can open a vendor’s file.

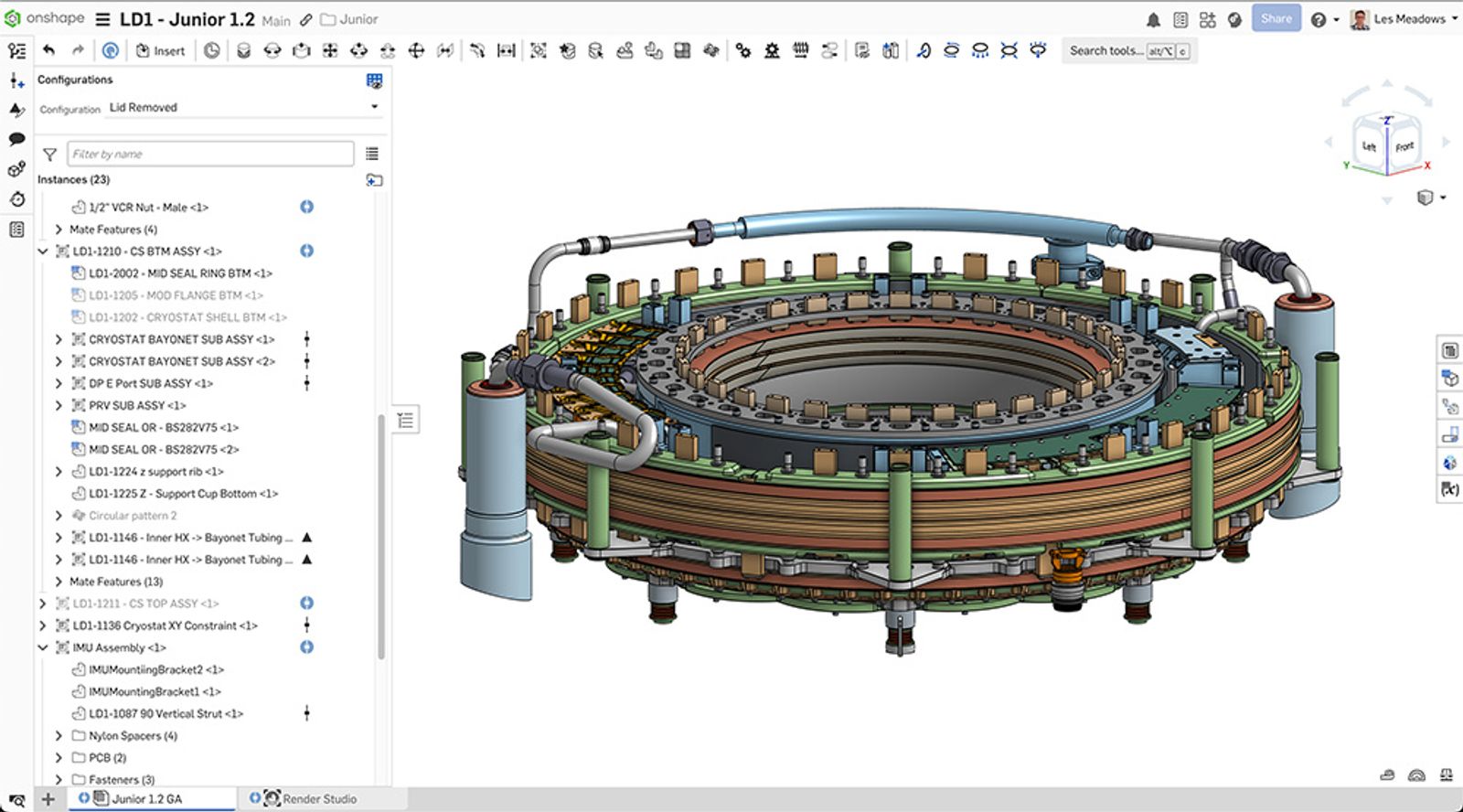

With Onshape, a streamlined design iteration process at CIXI. Read the case study.

The Hidden Cost: Legacy File-Based CAD

For the last three decades, the engineering world has accepted a workflow that is fundamentally broken. We have accepted the “Serial Workflow” as a necessary evil of mechanical design.

In a traditional file-based CAD environment (even those with expensive PDM systems attached), data is locked in files. Because a file can only be reliably edited by one person at a time, the workflow becomes strictly linear.

- Engineer A opens the assembly to work on the chassis.

- Engineer B wants to work on the mounting bracket, but the assembly is "Checked Out."

- Engineer B waits.

Or, worse, Engineer B makes a local copy, does their work, and then spends an afternoon trying to manually merge their changes back into the main assembly, praying they don’t accidentally overwrite Engineer A’s work.

This is Data Friction. It is a hidden tax on every single interaction in your engineering department.

The Accelerator: Cloud-Native & Parallel Processing

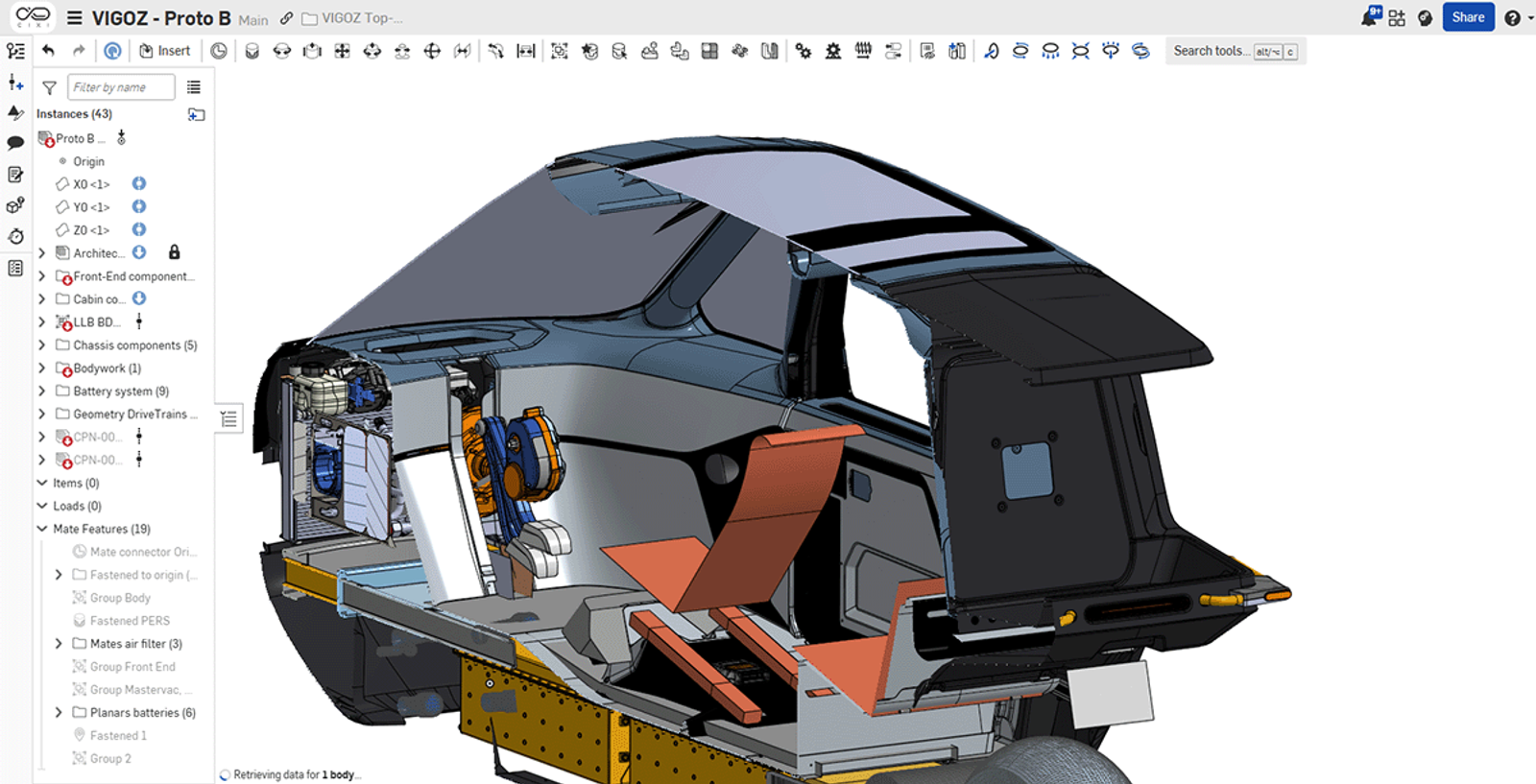

When using Onshape, faster Iteration at Open Star Technologies. Read the case study.

To uncap your Business Velocity, you must move from serial processing to parallel processing. This requires a shift from file-based CAD to cloud-native CAD.

Cloud-native platforms like PTC’s Onshape rely on database architecture, not file architecture. This distinction may seem subtle technically, but massive operationally. In a database, there are no files to copy or lock. There is a “Single Source of Truth” that exists in the cloud.

This enables Simultaneous Collaboration.

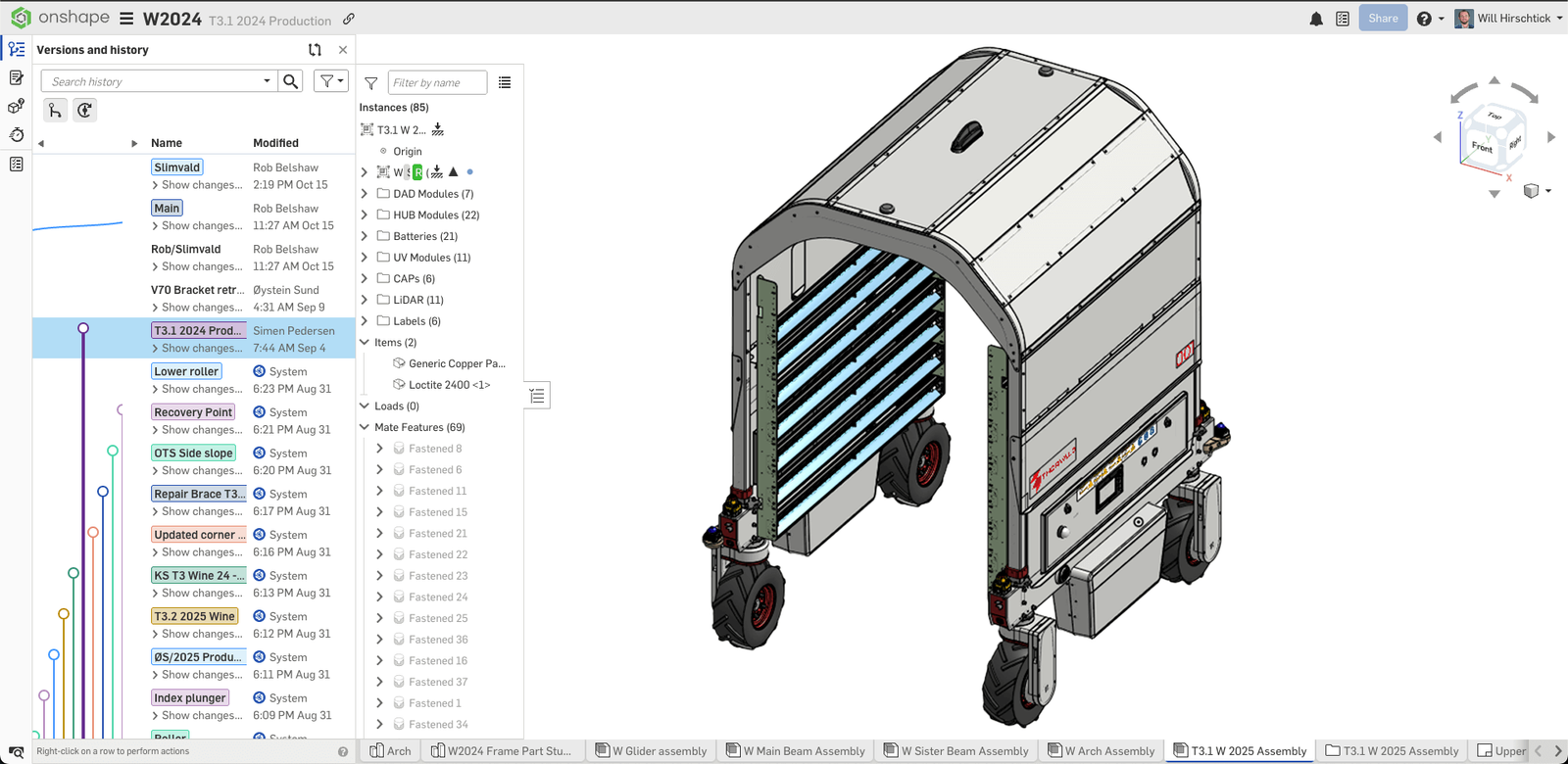

Software teams have used “Agile” methodologies for years—sprints, branching, and merging. Onshape brings these capabilities to hardware.

- Branching: An engineer can take the main design, create a “Branch” to test a radical new design, and iterate freely without affecting the main assembly.

- Merging: If the experiment works, they can merge that geometry back into the main design instantly. If it fails, they can leave the branch as is—documenting the experiment. No "Save As" confusion.

If Design Velocity is the number of iterations you can achieve per week, parallel processing acts as a multiplier. Further, cloud-native CAD removes the IT Footprint. There are no installs, no license servers to ping, and no version incompatibilities.

The Ripple Effect on Business Beyond Design Teams

30-40% faster design cycles through real-time cloud collaboration at Saga Robotics. Read the case study.

When you remove the bottleneck in the design phase, the velocity flows downstream to the rest of the organization. Design data is the lifeblood of a hardware company; when it flows freely, every department becomes faster. For example, integrating Onshape and Arena PLM accelerates business processes by connecting design and supply chain data instantly.

How it works:

- Design to BOM: When an engineer finalizes an assembly in Onshape, a single action syncs the complete Bill of Materials (BOM) to Arena. During setup, category mappings ensure accurate flow of part numbers, descriptions, and materials.

- BOM Enrichment: Arena enhances the BOM by adding crucial information not needed in the CAD environment, such as supplier data, manufacturer part numbers, and supply chain risk intelligence.

- Real-Time Procurement: Procurement gains immediate visibility into component selections as engineers add them, eliminating the weeks-long delay previously associated with formal BOM releases.

- Simultaneous Collaboration: This connectivity enables concurrent work streams. For example, mechanical engineers can model the PCB outline in Onshape for fit checks, while the purchasing team simultaneously sources components and uses Arena's embedded Supply Chain Intelligence to find alternative parts.

This system ensures that each discipline operates effectively within its optimal environment while maintaining a live, connected data flow.

Das Onshape Discovery-Programm

Erfahren Sie, wie qualifizierte CAD-Experten Onshape Professional bis zu 6 Monate lang nutzen können — kostenlos!

Latest Content

- Fallstudie

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 Mehr Infos

- Blog

- Evaluating Onshape

- Zusammenarbeit

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 Mehr Infos

- Blog

- Kunden und Fallstudien

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 Mehr Infos

- Blog

- Evaluating Onshape

- Bildungswesen

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 Mehr Infos