The Challenge

Avidbots is the developer of Neo, the world’s leading fully autonomous floor-scrubbing robot for large commercial spaces – such as airports, shopping malls, hospitals and warehouses. The Avidbots product development team was seeking a better way to share its updated CAD data across their internal departments and external partners worldwide. Using a file-based CAD system, the company had been experiencing workflow delays when exporting their new design changes in PDFs and uploading them to shared folders, resulting in half the team’s day being devoted to data management.

Results

- Onshape’s real-time data management enabled the Avidbots engineering team to reclaim 50% of its product design time which used to be devoted to synching CAD changes across the organization.

- Onshape’s Sharing feature allows design teams to instantly and securely share CAD models with outside partners with just a web link.

- Facilitating more iterations and experimentation, a comprehensive Edit History tracks who made what change and when, allowing teams to return to any prior state of the design process if desired.

With Onshape, our collaboration process is much more fluid and allows everyone more direct access to the CAD models. It frees us up to focus on our highest value tasks.’’

Cleanliness has always been a public health and worker safety priority for companies, but the worldwide COVID-19 pandemic has magnified its importance for obvious reasons. The bigger the facility, the bigger the challenge – dust, grime and germs don’t wait for the maintenance staff to finish their rounds and are unforgiving if someone inevitably misses a spot.

Based in Kitchener, Ontario, Avidbots is the developer of Neo, the world’s leading fully autonomous floor-scrubbing robot for large commercial spaces – such as airports, shopping malls, hospitals and health care facilities, factories, schools and warehouses. Some of the world’s busiest airports, including five of the top 10 airports at the prestigious 2020 World Airport Awards by Skytrax, currently rely on its Neo robots. Multinational companies such as 3M, GE, Toyota, DHL and Hitachi, are also deploying the autonomous floor scrubbers to ensure a safe and healthy work environment.

Company founders Pablo Molina and Faizan Sheikh, both graduates of the nearby University of Waterloo School of Engineering, grew up loving futuristic kids TV shows like “The Jetsons” and Japan’s cyborg hero “Jiban.” If you look at the smiling face built into the design of the Neo 2, it’s not difficult to imagine the machine having its own personality.

The remotely monitored sanitation robots are not meant to replace human maintenance workers, but to free them up to perform higher-skilled tasks.

“Labor represents anywhere from 70 to 85 percent of the overall cleaning cost in the marketplace,” notes Jeff Schrantz, VP of Global Sales for Avidbots. “And now with COVID, organizations are seeing it's much harder to staff those jobs, and some workers are requesting health-risk premiums on top of that. So Neo can really help with high labor costs.”

“We also know that customers are challenged with high employee turnover and a high level of absenteeism,” he says. “I was speaking recently with an executive at a company with facilities all over the world. He told me, ‘We can neither quantify nor qualify what takes place in our facilities when there's nobody there but the cleaning crew. Now we have visibility through the use of metrics in our Avidbots Command Center to both quantify and qualify the clean.’"

Schrantz adds that using Neo as a fully autonomous cleaning solution is invaluable in isolated COVID-19 hospital wards where human contact is kept to a minimum. He described his recent experience doing a product demonstration at a hospital in a Middle Eastern country:

“The minister of health was standing in the hallway looking through a pane glass window knowing he needed to limit personnel in the ward,” he recalls. “Our robot was navigating around hospital beds with patients in them, and navigating around health care workers because that was the only way that they could clean the floors in that COVID isolation ward. Watching this video made me so proud of what we’re doing here at Avidbots.”

Powered by the Avidbots AI Platform, Neo 2 is continuously aware of its surroundings and can navigate around obstacles, avoiding anyone or anything. This capability is extremely valuable in unpredictable environments, such as a warehouse with workers and forklifts constantly moving. In this video, you can see the robot respond to an employee pulling a chair away from a table and leaving it in the middle of the floor:

Communication is a Bigger Challenge than Mechanical Design

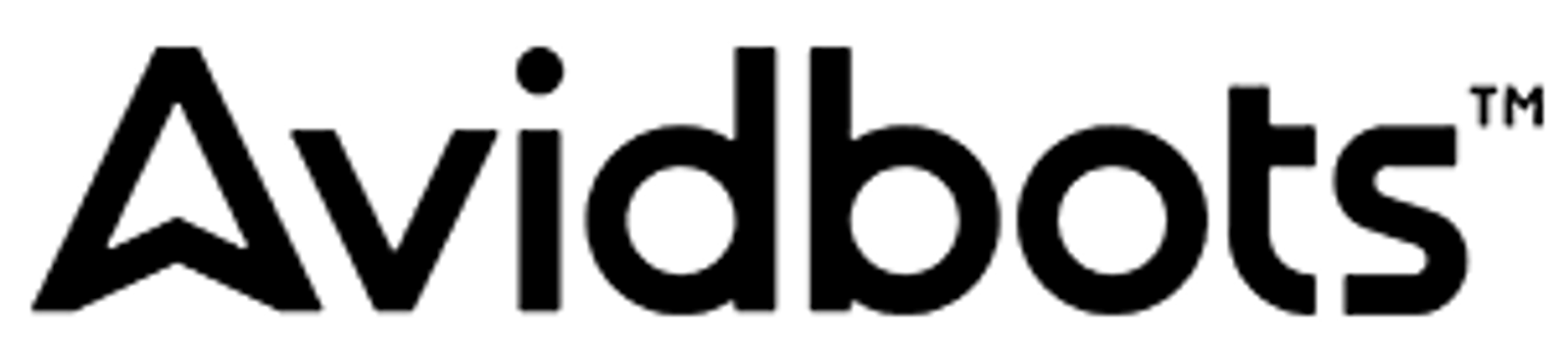

The Neo 2 represents the eighth-generation of Avidbots’ sanitation robots. The latest iterations have focused on improving Neo’s cleaning abilities and further enhancing its autonomy.

“Our technology for obstacle avoidance is something that's unique in the industry and really is our key differentiator in the market,” says Ian Gardiner, Senior Mechanical Engineering Specialist in Mechatronics Engineering. “Floor cleaners have been around for decades. We’re not inventing the form of the floor cleaner; we’re inventing the autonomy of the floor cleaner.”

According to Gardiner, the challenge of sharing updated product design data across their internal departments and external partners has historically been more challenging than the mechanical engineering tasks themselves.

“Our design team is working on improvements every day. We know what we want to build. Our challenge has been communicating rapid iterations across the organization.” he says. “And not just in our local facility, but across a set of teams that are distributed worldwide because we also work with partners.”

“We eventually want to securely share product data, part numbers and build specifications globally. Internally, we have our purchasing, manufacturing, service and customer support teams. Externally, we have vendors and service partners. They need accurate, current and historical data to do their best work. One reason for moving to Onshape was to facilitate that collaboration and that sharing of our data,” Gardiner adds.

The Avidbots product development team switched to PTC’s Onshape cloud‑native product development platform in early 2020 after being frustrated by how their file-based on-premise CAD system was slowing down communication.

“Email and spreadsheets were our typical way of sharing information, but with these older CAD systems, a lot of your data gets buried within the system. You have to purchase extra licenses and/or add-ons to make CAD available to people,” he recalls. “So we would export PDF drawings and put them into folders that people could access. But these are disconnected from the real models that are being developed day by day. Half our team’s time used to be spent constantly reproducing and updating changes.”

Onshape’s real-time data management provides one single source of truth for product designs across the organization. Whenever one member of the team makes a change, everyone else can instantly see it. A comprehensive Edit History tracks who made what change and when, allowing teams to return to any prior state of the design process if desired. In addition, Onshape’s Sharing feature allows design teams to instantly share CAD models with other departments or outside partners with just a web link.

“With Onshape, our collaboration process is much more fluid and allows everyone more direct access to the CAD models,” says Gardiner. “It frees us up to focus on our highest value tasks which are solving design challenges like the best way to capture squeegee water. We can’t leave any streaks on the customers’ floors.”

Beyond Scrubbing Floors: Future Applications

The Greater Kitchener-Waterloo area is one of Canada’s hotbeds of digital innovation. Not only because of the University of Waterloo, but also due to renowned startup incubators such as Communitech.

“There’s a big talent pool here and a real appetite for creation and sharing ideas. Avidbots is part of that culture and I’m excited about how our core technology can be applied across a lot of applications,” says Schrantz.

“Neo is now our main cleaning robot, but our core technology is artificial intelligence, the mapping and understanding of objects, and dynamically adjusting around those objects,” he adds. “We're going to start to use Neo as a platform for all kinds of industries and adapt our physical form to meet different customer needs.”

“This is a platform that is only limited by our ability to dream and dream big. So our future robots might be used for disinfection, to monitor temperature and humidity, maybe check for gas leaks in a building, look for tears in a carpet, or make deliveries,” Schrantz says. “Neo's the magic carpet that we are all traveling on. And we are only limited by our own imagination and the imagination of our clients and prospects to challenge us to do even greater things.”