05:22

In Japanese, “kaikaku” means radical change. It is the act of reforming and redesigning production processes to make a business lean, flexible, and current.

For the London-based startup KAIKAKU, the term is an embodiment of what it hopes to do in the restaurant industry: “radically transform restaurant chains by building a next-gen integrated platform powered by robots and AI.”

That’s part of KAIKAKU’s mission statement. The company’s leaders believe that restaurant employees and their customers will benefit from the efficiencies of a robotic system called Fusion that handles the “tedious” tasks of food preparation. They would know. They’ve been developing – or you could say “cooking” – Fusion right in their own healthy foods restaurant. Common Room doubles as a KAIKAKU laboratory. With big servings of AI, they’re refining Fusion as it gains experience making meals for Common Room customers.

“It’s very much a living lab,” said Ivan Tregear, a KAIKAKU co-founder and Chief Technology Officer.

Robots Trying to Make a Lasting Dining Experience

KAIKAKU co-founder Josef Chen experienced the grind of food service in childhood while working in his family’s Chinese restaurant in Austria. Cutting and peeling vegetables, marinating meats, brining chicken, making sauces, and taking other time-consuming prep steps – he knew there had to be a better way. It finally hit him: robots could handle the repetition of that critical but unending work.

Flash forward to 2023, when Chen enlisted Tregear and two others to start KAIKAKU and Common Room. They initially considered programming the physical actions behind food prep into another company’s service robots but realized the cost would turn away restaurants that already operate on a thin margin. “And many robots are time consuming and difficult to interface with one another,” Tregear said. “We knew we had to make the most of a scrappy, dirty, and cheaper robot that we made ourselves.”

Developing and testing robots in a type of restaurant that requires relatively minimal prep work seemed like the “lowest-hanging fruit” before the team eventually programs the robots to figure out more refined tasks such as chopping ingredients and cooking. At Common Room, KAIKAKU developers and programmers work out of sight of customers, who place their orders on a kiosk and fetch their meals from employees at a counter.

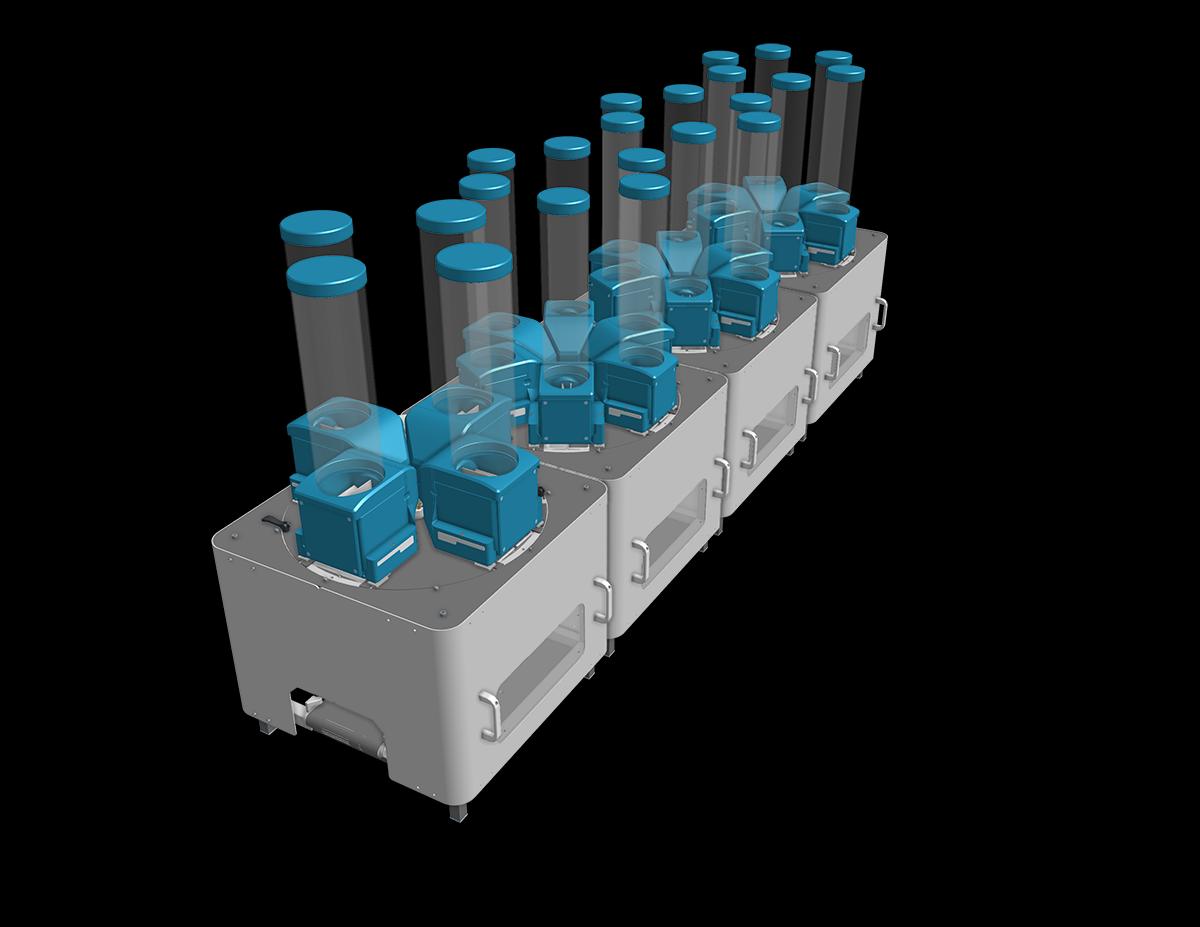

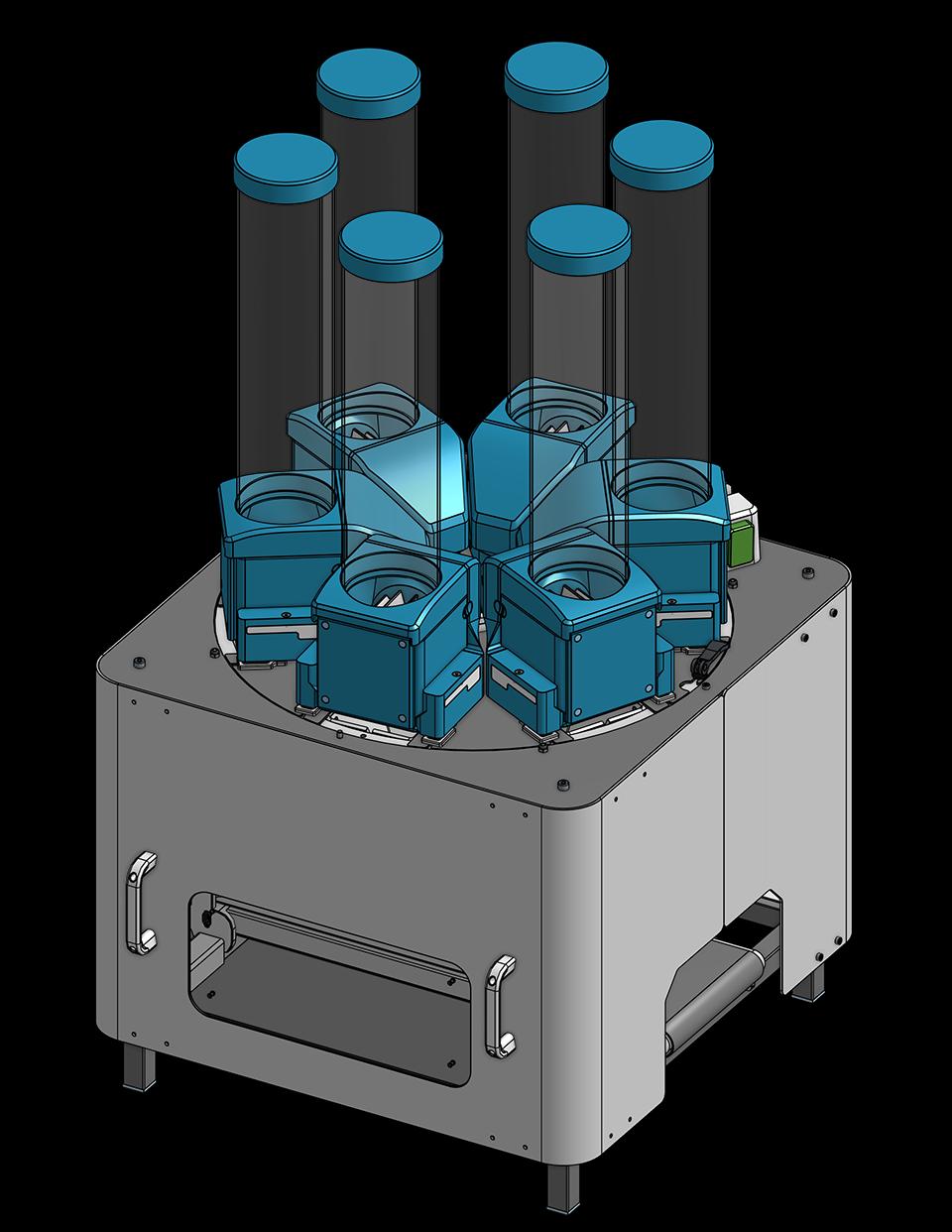

If customers were to peek behind the Common Room curtain, they’d see that Fusion isn’t a robot along the lines of C-3PO from “Star Wars.” Rather than arms and legs, Fusion uses a series of tubes to dispense vegetables and other salad ingredients onto a conveyor belt. At the end of the process, an employee behind the restaurant counter can add salad dressing, a sauce, or a protein like chicken. “And then they hand the customer a bowl with a smile,” Tregear said.

“Ideally, at maximum output, you could get a bowl out every 15 seconds,” he added. “A robot frees up manual labor, basically preparing all the bowls and doing all the menial and tedious tasks. That allows us to still have humans as an integral part of the store experience: the hospitality part.”

From Collaboration to Version Control: Cloud CAD Comes Through

The KAIKAKU team has big ambitions for Fusion. Restaurants hoping to leap into KAIKAKU’s futuristic vision of food service will purchase a cloud-based system that includes the robot modules that prep food, ordering kiosks, and AI capabilities such as quality assurance, customer behavior analytics, and predictive decisions based on sales data.

As they continue to develop and refine Fusion, one of the team’s biggest challenges is contending with how the physical properties of foods vary not just in size and shape but also storage temperature. But they’ve seemed to figure it out. “We've got to the point where for prepping most ingredients, Fusion is as good or better than a human's accuracy,” Tregear said. “Dialing that in even more is big for us.”

To get there, KAIKAKU relies on the Onshape Startup Program, an initiative that gives qualifying hardware startups access to Onshape Professional, a fully cloud-native CAD and PDM package with integrated simulation and rendering tools. The Common Room employees who hand customers their food and clean tables have a dual role; they are also on the KAIKAKU development and engineering side and are taking advantage of Onshape on computers and 3D printers.

For one, Onshape's Part Studios has “saved us much time and hassle” when creating the different configurations of Fusion, Tregear said. Fusion has an elaborate parametric modular design, he said. “You’ve got different stations which are separate entities. You have two of them, or four of them, and so on depending on how many ingredients. And the dispenser bases are different sizes to accommodate the sizes of ingredients. They’re all rendered in the final master assembly, and Onshape has helped us set that up.”

Tregear hadn’t used Onshape before joining KAIKAKU. He was instantly impressed by the ease with which he and his team collaborate. The key is Onshape's versions and history panel, which enables the team to either create view-only versions or branch a version to create a new workspace. “That we have this sort of git-style version control is amazing, especially for us engineers who are software-minded,” he said. “That doesn’t really exist in SOLIDWORKS.”

Being able to merge changes from a document version or workspace into an active document workspace “is also just insane,” Tregear said. “That has also saved us time, being able to do something you can't do in regular SOLIDWORKS, and that’s basically having two people work on the same file. In SOLIDWORKS, that is a surefire way to break everything. That we now can just go from a couple versions, merge, and come back into our own workspace is awesome.”

Establishing workflows through Onshape release management has also helped development. “It’s really good at tracking the sort of ground truth,” he said. “We iterate quickly. A robot you see one day is not the same as the one you saw two weeks ago. Being able to clearly tag and mark what a release and generation of hardware it is has been super helpful.”

Tregear is looking forward to leaning on Onshape even more as KAIKAKU prepares for a new design cycle to create the next version of Fusion. “It has been a pleasure to use Onshape and take advantage of the Startup Program. The support we’ve had has been immeasurable.”

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and analytics in one system.

Latest Content

- Case Study

- Industrial Equipment & Machine Design

Reframe Systems: Transforming Homebuilding with Digital Automation and Cloud-Native Onshape

09.25.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more