The Challenge

Reframe Systems is revolutionizing residential construction by applying industrial automation and digital design to an industry that hasn’t fundamentally changed in decades. Founded by former Amazon robotics engineers, Reframe Systems blends robotic automation, software-driven workflows, and digital design to solve urgent housing, labor, and climate challenges facing the residential construction industry and communities across New England.

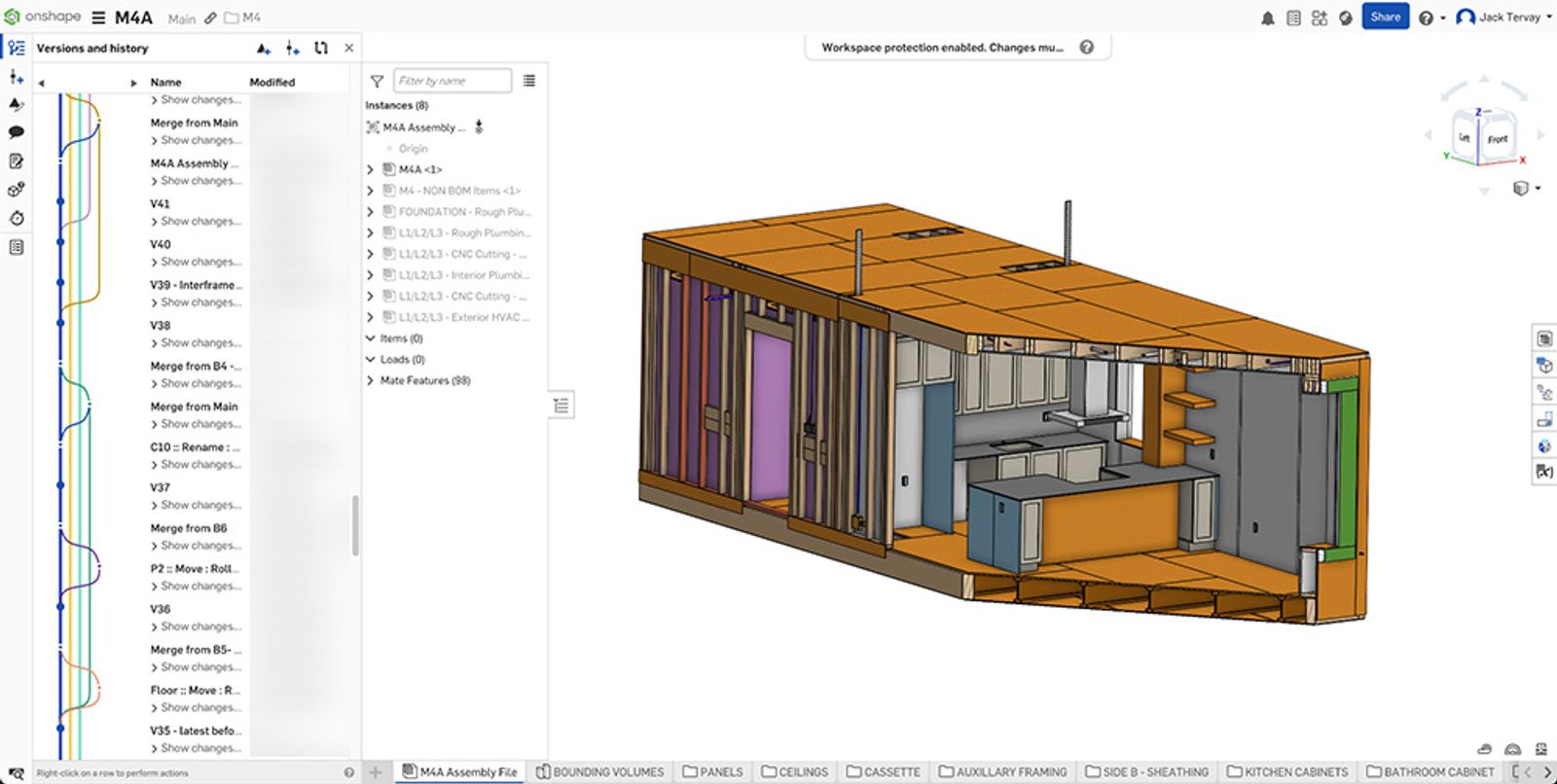

By using PTC’s Onshape as the foundation of its high-fidelity digital twin and custom automation workflows, Reframe has built a vertically integrated construction platform that enables rapid iteration, mass customization, and paperless production — transforming how developers and builders deliver sustainable, cost-effective housing at scale.

Results

- 500-home annual capacity per microfactory with only $5M capital investment

- 3–4x faster modeling time for wall framing using Onshape custom features

- Reduced design feedback response time from days to minutes

- Streamlined, paperless production with cloud-native CAD and built-in digital work instructions

- Increased workforce agility, enabling apprentices to contribute meaningfully from day one

Onshape doesn’t just help us model faster; it lets us build smarter. It’s the foundation for scaling sustainable housing, nationwide.’’

Bringing Automation to an Aging Industry

The U.S. construction sector is facing a seismic shift. With over 40% of skilled construction labor set to retire in the next decade and ongoing housing shortages, the industry is under pressure to build faster, with fewer people.

Reframe Systems’ mission is to apply industrialization best practices, automation, digital design, and scalable workflows to construction. The company is currently focused on infill markets and smaller developers (10–100 unit projects) that require localized, flexible production. Rather than building one-size-fits-all homes, Reframe’s innovation lies in its ability to tailor designs to local zoning, site, and code requirements without sacrificing speed or efficiency.

“We didn’t come from construction. That’s why we saw an opportunity to rethink the entire process,” says Felipe Polido, Co-Founder and Head of Technology. “We asked: Why can’t homes be built like products: digitally designed, robotically fabricated, and assembled quickly and cleanly?”

The Microfactory Advantage

At the heart of Reframe’s model is the microfactory: compact, 50,000 sq. ft. production facilities (about the size of a home improvement store garden center) that are purpose-built to serve nearby urban areas. Each microfactory requires just $5 million in capital investment and can produce up to 500,000 square feet of built environment annually, equivalent to roughly 500 homes per year. This cost-effective model allows Reframe to scale rapidly while maintaining quality and flexibility.

Unlike massive, centralized modular factories, Reframe’s microfactories are embedded within the communities they serve. This proximity offers several advantages:

- Localized labor: The same electrician assembling a panel in the factory may be the one installing it onsite.

- Faster iteration: Feedback loops between design and production happen in minutes, not days or weeks.

- Reduced environmental impact: Local production means less trucking, lower emissions, and faster delivery.

“Our long-term vision is a microfactory for every five Home Depots in the country,” Polido says. “They’re low-capex, flexible, and let us bring industrialized housing to any market.”

Onshape as the Digital Thread Foundation

Although Reframe Systems initially experimented with desktop CAD, the team quickly realized they needed more than traditional BIM. Onshape’s modern CAD environment, particularly its automation capabilities and custom features, offered them the fidelity and flexibility required to build a true digital thread.

“With Onshape, we’re not just modeling buildings — we’re encoding how they get built,” says Ethan Keller, Design Automation Lead. “It’s the backbone of our digital thread, turning design data directly into machine instructions, factory tasks, and even zoning-aware AI optimizations.”

Using cloud-native Onshape, Reframe creates detailed models that drive:

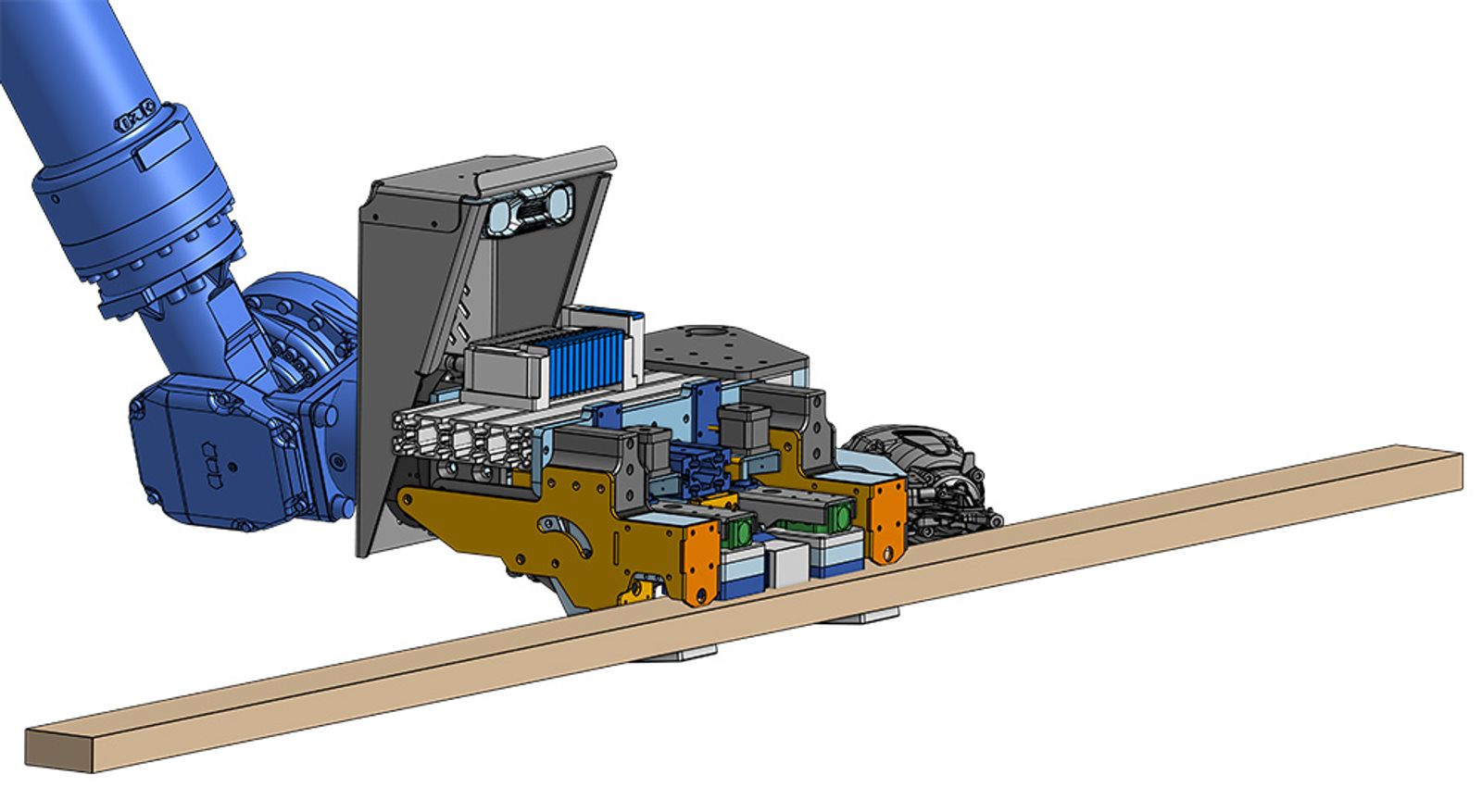

- Machine instructions for cutting saws and robotic arms

- Work instructions for the factory floor via their custom app

- AI optimization for zoning compliance and materials selection

Each wall panel is fully defined in Onshape, including studs, sheathing, plumbing, and electrical cutouts. This model becomes the single source of truth across design, fabrication, and installation.

Built in the Cloud, Powered by AWS

Onshape’s foundation on Amazon Web Services (AWS) gives Reframe the enterprise-grade reliability and security it needs to industrialize homebuilding. While Onshape provides the CAD and data management capabilities that drive Reframe’s digital thread, AWS ensures those capabilities are delivered with proven uptime, global scalability, and the same trusted infrastructure relied on by Fortune 100 companies and government agencies.

“Onshape has established itself as a pioneer in cloud-native product development, offering professional-grade CAD capabilities and integrated data management that’s revolutionizing how teams collaborate,” says Mark Frost of AWS. “And by leveraging AWS’s global infrastructure, Onshape delivers a unique platform that eliminates traditional IT burdens while enabling real-time collaboration.”

Because Onshape runs entirely in the cloud, Reframe can launch new microfactories without heavy IT overhead, help distributed teams collaborate in real-time, and guarantee that every stakeholder works from a single, always up-to-date model. The combination of Onshape’s modern CAD platform and AWS’s resilient cloud services allows Reframe to expand with confidence, knowing that their designs and production data remain secure, accessible, and continuously available.

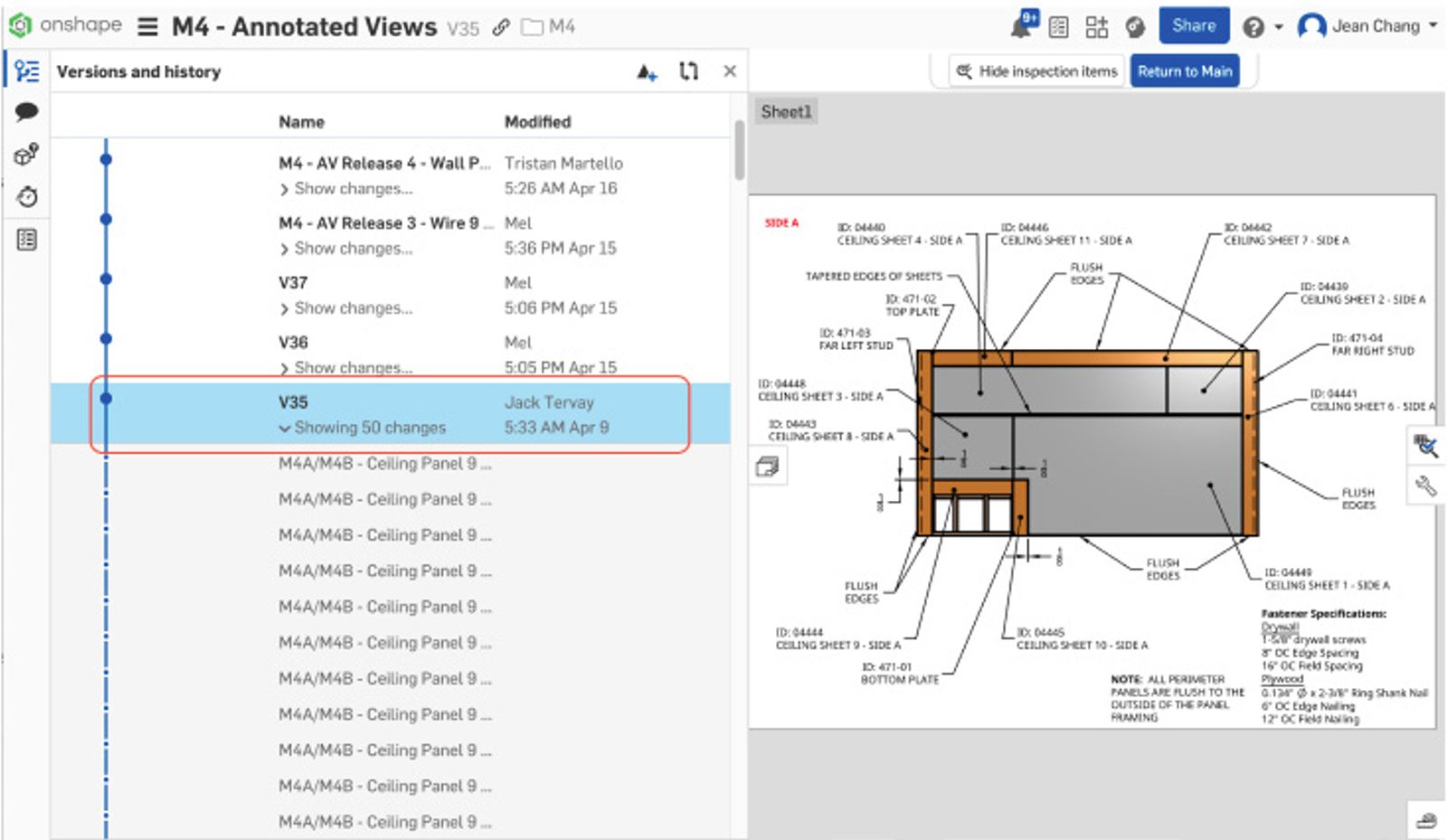

Codifying Construction Automation with Custom Features

To optimize its industrialized approach to construction, Reframe has developed a suite of custom FeatureScripts and automation tools within Onshape that codify their building logic and streamline every step of design through production. Onshape allows Reframe to create highly detailed, build-ready models faster and with fewer errors, unlocking both scale and flexibility.

“FeatureScript lets us embed our building logic directly into the CAD system,” Keller says. “It’s not just modeling, it’s programming a building.”

Here’s how Reframe’s team is putting Onshape’s automation capabilities to work:

Robotic wall framing reduces design time 75%

This custom FeatureScript generates a fully framed wall based on a selected wall type, automatically creating and placing all structural members (studs, plates, sheathing, plumbing cutouts, and more). Once manual and time-consuming, this process is now 3–4x faster, dramatically reducing the time needed to define wall structures across an entire project.

“This tool alone cut framing design time to a quarter of what it was,” says Polido. “And it’s just one of dozens of scripts we’re building.”

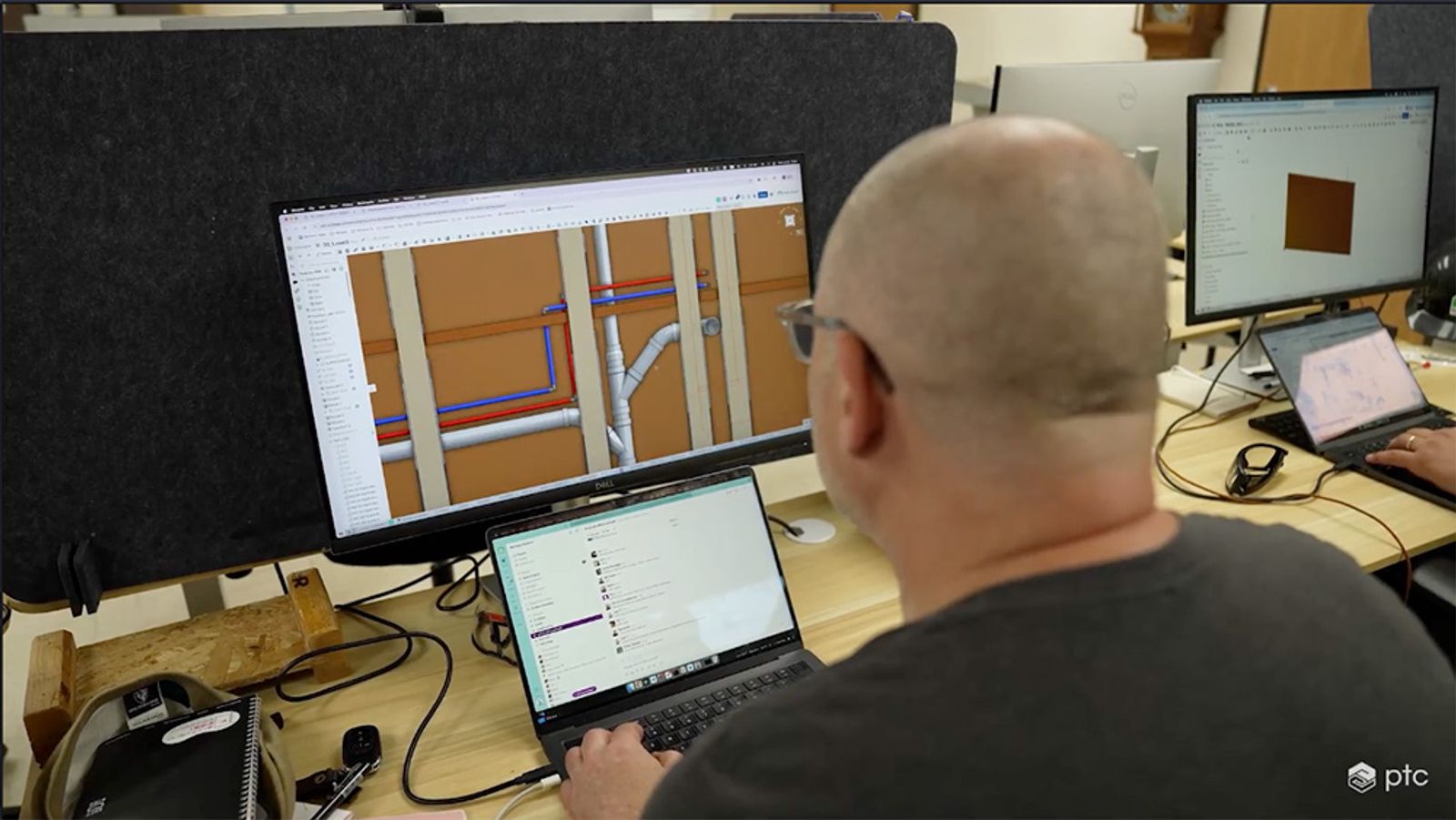

Standardized plumbing logic eliminates manual errors

Reframe uses a smart script to automatically place plumbing fittings from a standardized parts library based on layout conditions and design constraints. This ensures consistency across projects, eliminates manual placement errors, and allows modelers to focus on more complex design decisions.

Automated coring saves time & minimizes risk

Another FeatureScript handles the placement of holes for pipes and ducts, cutting precisely where needed based on the mechanical layout and the materials involved. By embedding this logic directly into the model, Reframe eliminates the need for manual measurements and reduces installation risk in the field.

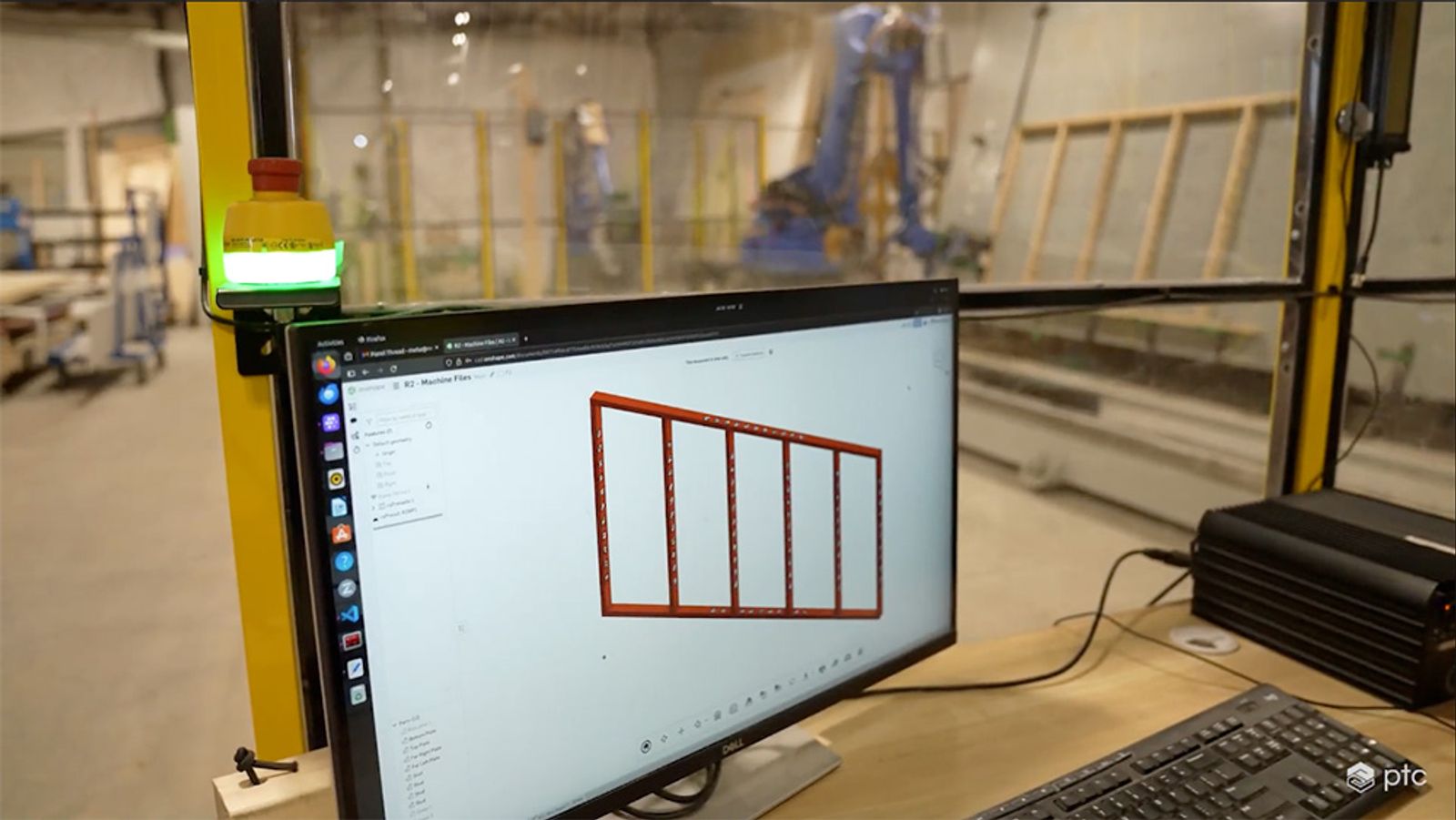

Converting CAD data to machine systems codifies carpentry

Reframe’s team developed a tool that converts CAD data directly into machine instructions for their automated saw system, similar to G-code for CNC machines. This replaces what would normally require a high-skilled, dedicated CNC programmer and allows a less experienced team to fabricate high-precision parts on demand.“With this setup, we’ve taken what used to be a specialized job and made it fully automated,” says Keller. “We’re codifying carpentry.”

Each of these custom tools feeds into Reframe’s broader digital twin strategy. Detailed models created in Onshape carry metadata that downstream tools like the robotic framing arm can use to make decisions and guide fabrication. For example, studs are marked with unique IDs that the robot scans and uses to pull assembly instructions directly from the model, enabling fully automated wall assembly.

“We’re building a system where the model isn’t just a drawing; it’s the factory’s brain,” says Polido.

With these tools, Reframe turns sketches into complete floors of framing in minutes.

“What used to take a day now takes an hour,” Keller explains. “And once the model’s built, our robotic framing arm can assemble walls using only the metadata embedded in the model.”

By automating and codifying what were once manual, error-prone steps, Reframe is driving consistent, scalable, and customizable construction.

From CAD Model to Assembly — No Paper, No Log

Reframe’s design pipeline is 100 percent digital, with every task assigned via an in-house app called Sidekick that connects Onshape models to on-the-floor instructions. Carpenters use tablets to view real-time, step-by-step guides tied to the live CAD model, ensuring accuracy and eliminating confusion.

If an issue arises, designers can update a model and re-release the work instruction to the floor in hours or minutes, compared to an industry standard 7–9 day response time for RFIs.

Giving an example, Polido shares: “One of our carpenters finished a task in Sidekick, which is the floor app that we use, and he noted that there was a call out missing. One of our designers noticed that and within basically nine minutes updated the drawings, re-released it, and it was back on the floor with the right fix.”

“The feedback loop is tight. That’s how we move fast and avoid costly rework.”

Scaling Skilled Labor Without More People

Automation has enabled Reframe to reduce the number of high-skill, seasoned experts required onsite, allowing apprentices and general laborers to handle much of the assembly work. The company's robotic systems take on repetitive, high-risk framing tasks, freeing up skilled tradespeople to focus on value-add work like finishing and inspections.

Their Boston-area factory produces 3–5 wall panels a day, and they've built over 1,000 linear feet of wall assemblies with robotic assistance.

Looking Ahead

With factories planned for Los Angeles and beyond, Reframe’s scalable, repeatable system positions the company to rapidly deploy industrialized housing solutions across the U.S. while fulfilling local customization requirements and minimizing environmental impact.

At the center of it all is Onshape: the core infrastructure powering the logic, automation, and speed behind Reframe’s breakthrough system.

“Onshape doesn’t just help us model faster, it lets us build smarter,” says Keller. “It’s our foundation for scaling sustainable housing, nationwide.”