05:45

Managing the intricate relationships between components in complex product assemblies presents a challenge for designers using CAD (computer-aided design) software. Ensuring that components fit together correctly, function as intended, and can be efficiently modified requires careful planning and robust design methodologies.

Top-down design offers a powerful approach to address these challenges, enabling design teams to define the overall structure and interdependencies before diving into individual part details, ultimately ensuring parts fit together the first time and function as expected.

What is the Top-Down Design Approach?

The top-down design methodology fundamentally reverses the traditional part-centric approach. It begins with the "big picture"—the overall system, the conceptual layout of the assembly, or a clear definition of the product's intended function and form. The emphasis is on establishing the design intent, critical interdependencies, and spatial relationships between major components or subsystems at the outset.

This methodology involves progressively breaking down the complex system into smaller, more manageable subsystems and components, refining the details at each level. Often, this starts with defining global parameters, shared datums, or simplified representations (placeholders) for the main subcomponents before adding intricate details.

Onshape's cloud-native architecture provides a unique foundation for implementing top-down design methodologies, offering distinct advantages over traditional file-based CAD systems. Its integrated environment for modeling, assembly, data management, and collaboration enables seamless and robust relational design workflows.

Let’s take a look at 7 ways Onshape enables a better top-down design approach.

7 Ways Onshape Enables Better Top-Down Design Approach

Onshape Documents

Unlike traditional CAD where projects consist of numerous separate part files, an Onshape Document acts as a project container or workspace. A single Document can hold multiple tabs containing various types of project data: Part Studios (for part creation), Assemblies, Drawings, imported files (STL, IGES, PDF, images, videos), Variable Studios, and more.

This unified environment means all project-related information resides in one managed location, inherently facilitating the management of relationships between different design elements. Folders can be used within the Documents page for further organization. The Document itself is the unit of sharing, versioning, and collaboration.

Linked Documents

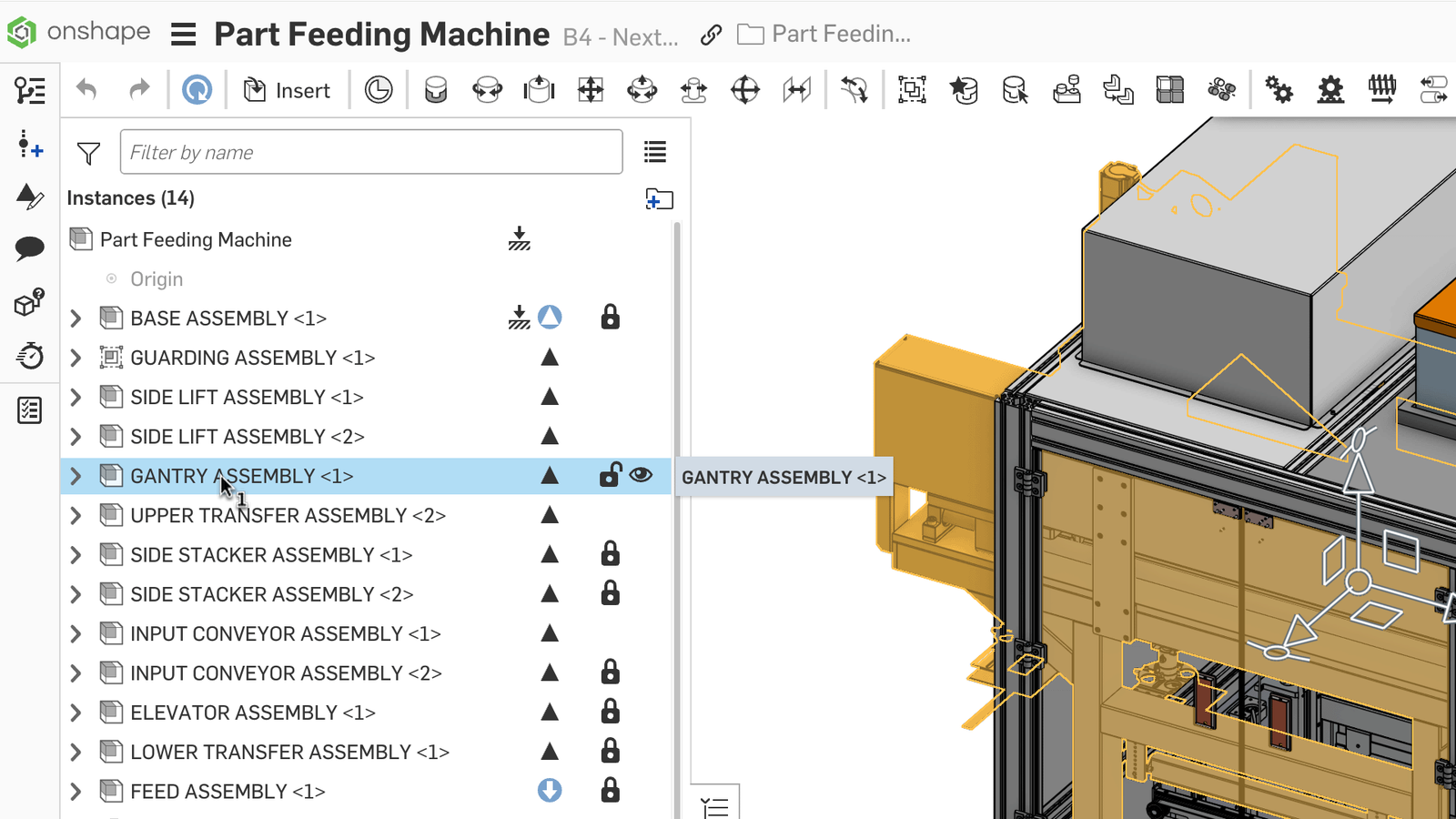

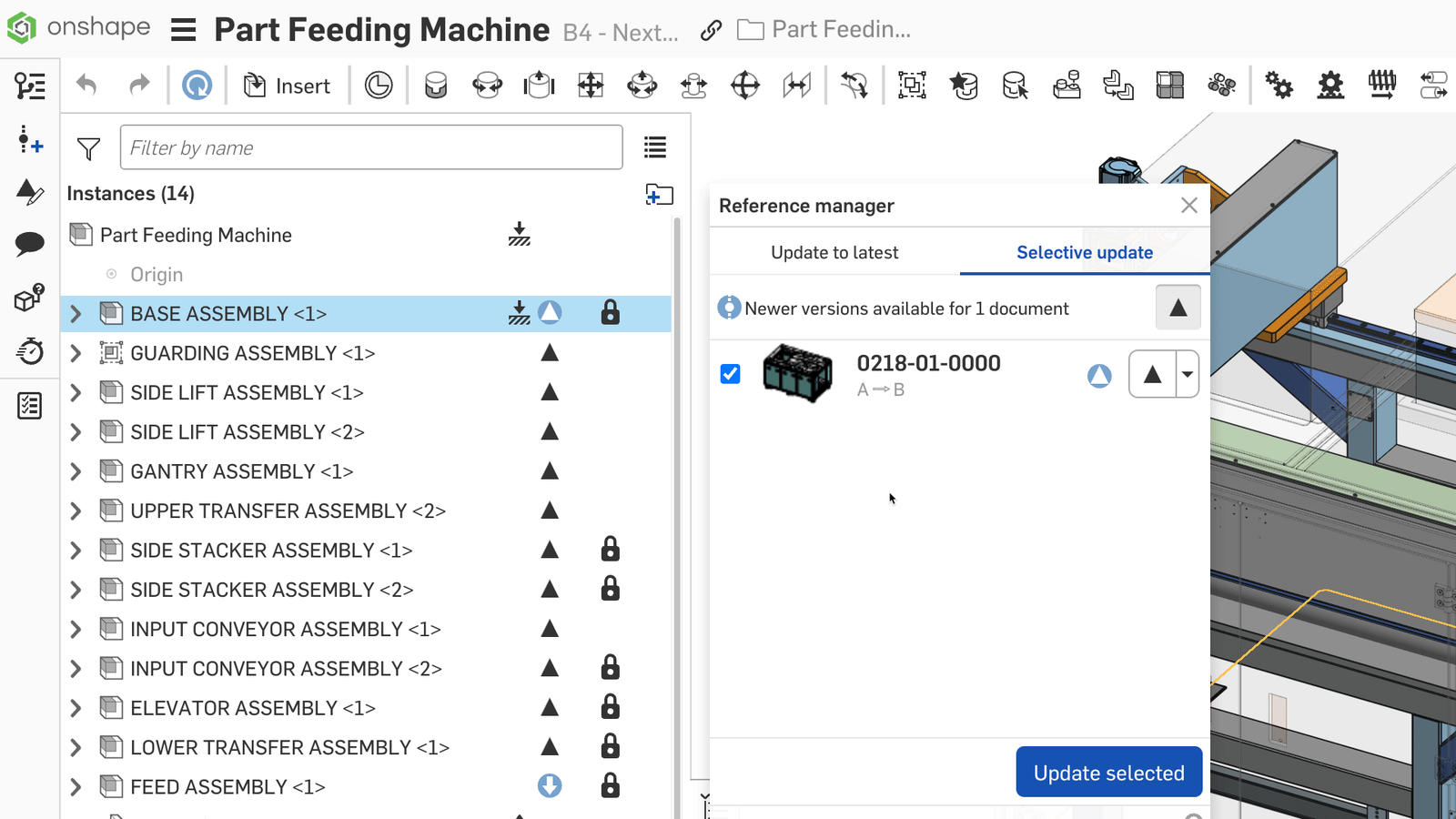

This feature allows elements—typically parts or subassemblies, but potentially sketches or surfaces, too—from one Onshape Document to be inserted and referenced within another Document.

This capability is fundamental for breaking large, complex designs into smaller, more manageable modules and for creating libraries of standard or frequently reused components.

Part Studios

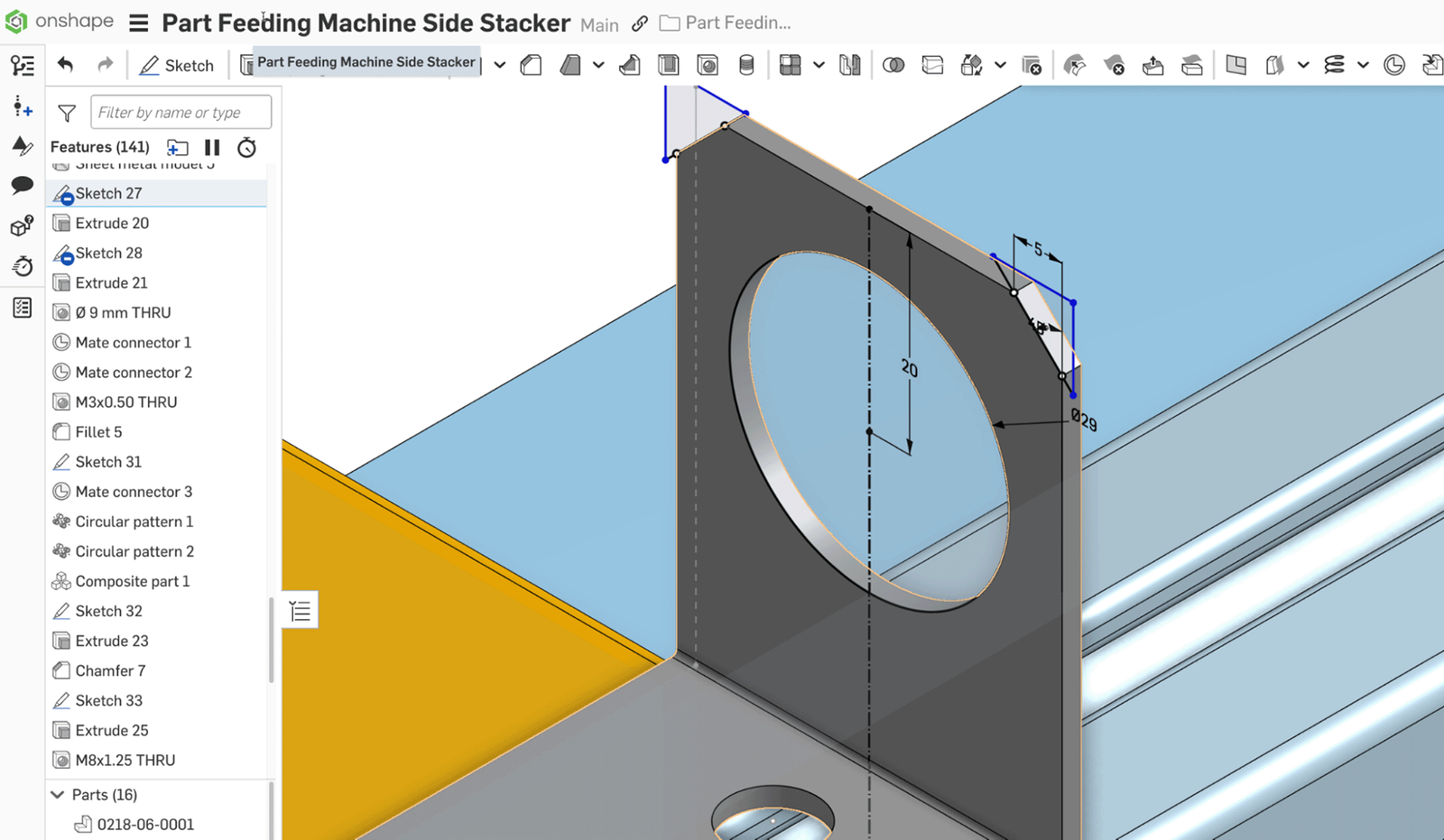

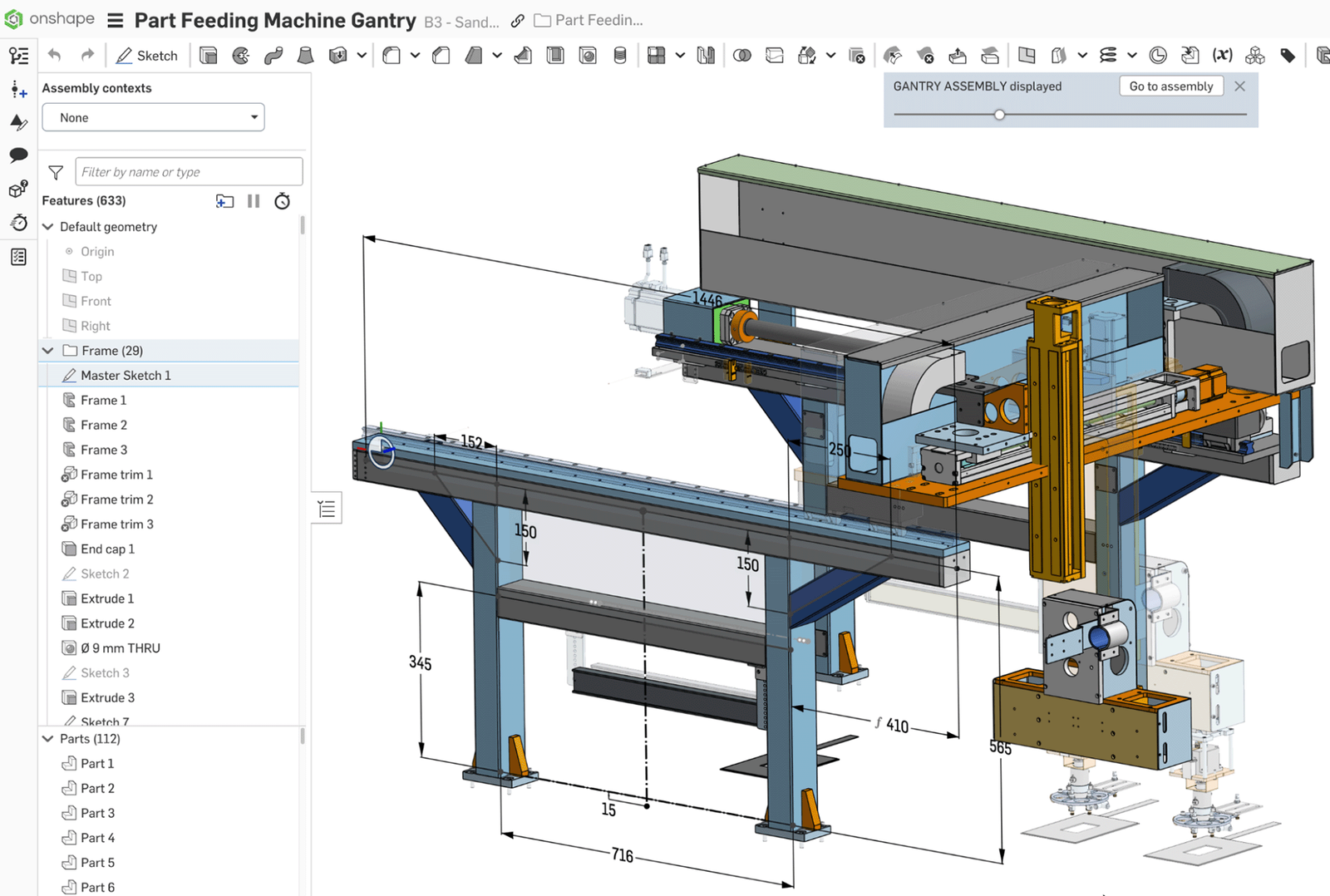

A Part Studio is a tab within an Onshape Document dedicated to creating and editing parts, surfaces, and sketches. Critically, a single Part Studio can contain multiple distinct parts. All parts created within the same Part Studio share a single, ordered, parametric feature list.

This shared history means that features can reference geometry from multiple parts within the studio, creating inherent, robust relationships that update automatically when shared features or sketches are modified.

Global Variable Studios

A Variable Studio is a dedicated tab where named variables (e.g., #OverallWidth, #HoleDiameter) are defined. These variables can then be referenced in sketches, feature dimensions, and patterns across multiple Part Studios and Assemblies within the same Document.

Changing a variable's value in the Variable Studio automatically updates all referencing dimensions parametrically throughout the Document. For top-down design, Variable Studios can be used to capture global parameters that can be shared across part studios and assemblies.

Assemblies

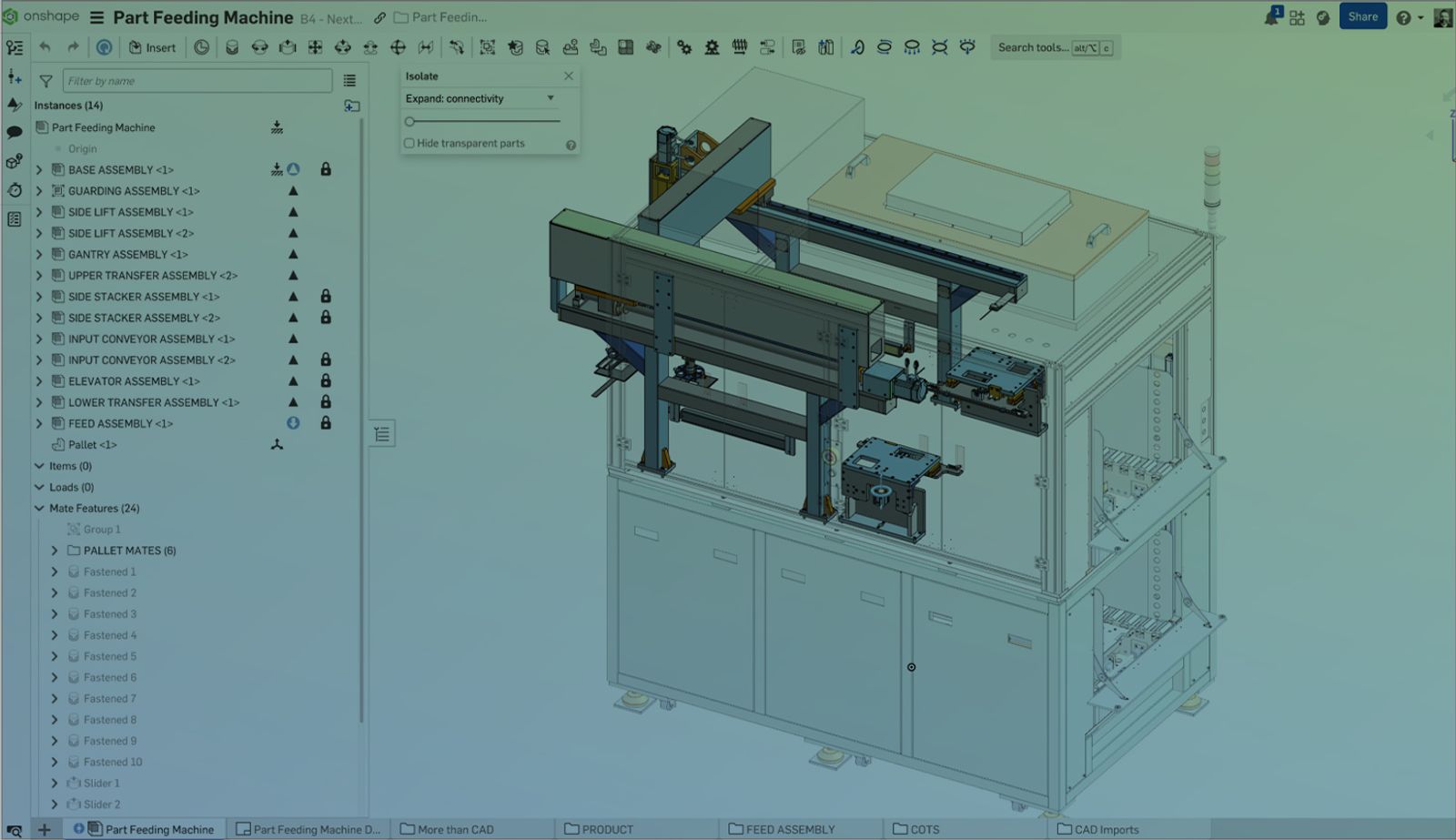

Assembly tabs are where instances of parts (from Part Studios within the same Document or from Linked Documents) and subassemblies are brought together.

In the Assembly environment, users define the kinematic relationships (how parts move relative to each other) using mates and establish the hierarchical structure of the product. Assemblies are primarily for defining structure, motion, and fit, rather than creating the fundamental part geometry itself.

In-Context Design

In-context design allows a designer to edit a specific part while viewing it within the visual context of its parent assembly. While editing, geometry from other assembly components can be referenced to drive the features of the part being edited.

If a reference is created, then Onshape tracks an “Assembly Context”. The Assembly Context is not a live link to the ever-changing assembly. Instead, it's a stable snapshot capturing the precise positions and geometry of the referenced assembly components at the instant the contextual reference was established.

This snapshot mechanism is what fundamentally differentiates Onshape's approach from the often fragile in-context links in traditional file-based CAD.

Versioning

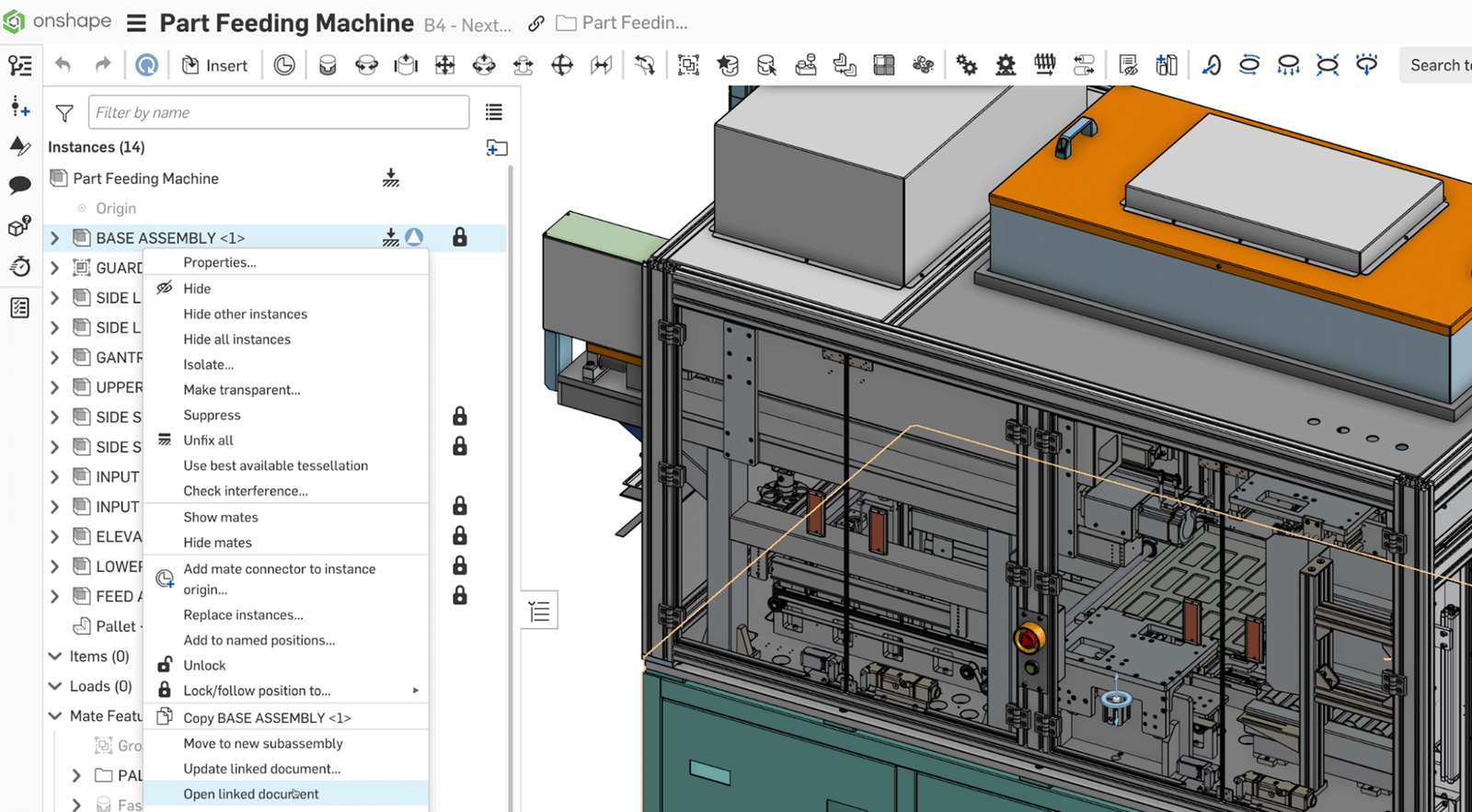

Versioning is the key to stability. When inserting an element from another Document, Onshape defaults to linking to the active workspace (the live, editable state) of the source Document.

While this provides immediate updates for changes made in the source workspace, it can lead to instability if the source part is under active development. The recommended best practice for stable top-down design, especially for standard parts or released subsystems, is to explicitly link to a specific, immutable Version or Release of the source Document.

The designer, always in control while working in Onshape, must consciously choose to update the link by right-clicking the instance/feature and selecting "Update Linked Document". This controlled update process prevents unexpected changes from cascading through assemblies and gives teams control over when external modifications are incorporated.

Cloud-Native CAD Enables Top-Down Design

Top-down design provides a powerful framework for managing complexity and ensuring the integrity of product assemblies. While the principles are not new, Onshape's unique cloud-native architecture and purpose-built features offer a modern, robust, and highly collaborative environment for implementing these strategies effectively.

With features like multi-part Part Studios for cohesive component design, Managed In-Context Design for reliable assembly referencing, and version-controlled Linked Documents for modularity and reusability. These tools enable teams to centralize design intent, maintain consistency, and simplify the iterative process, significantly mitigating the risk of broken links and update failures commonly associated with traditional top-down design methodologies.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more