The Challenge

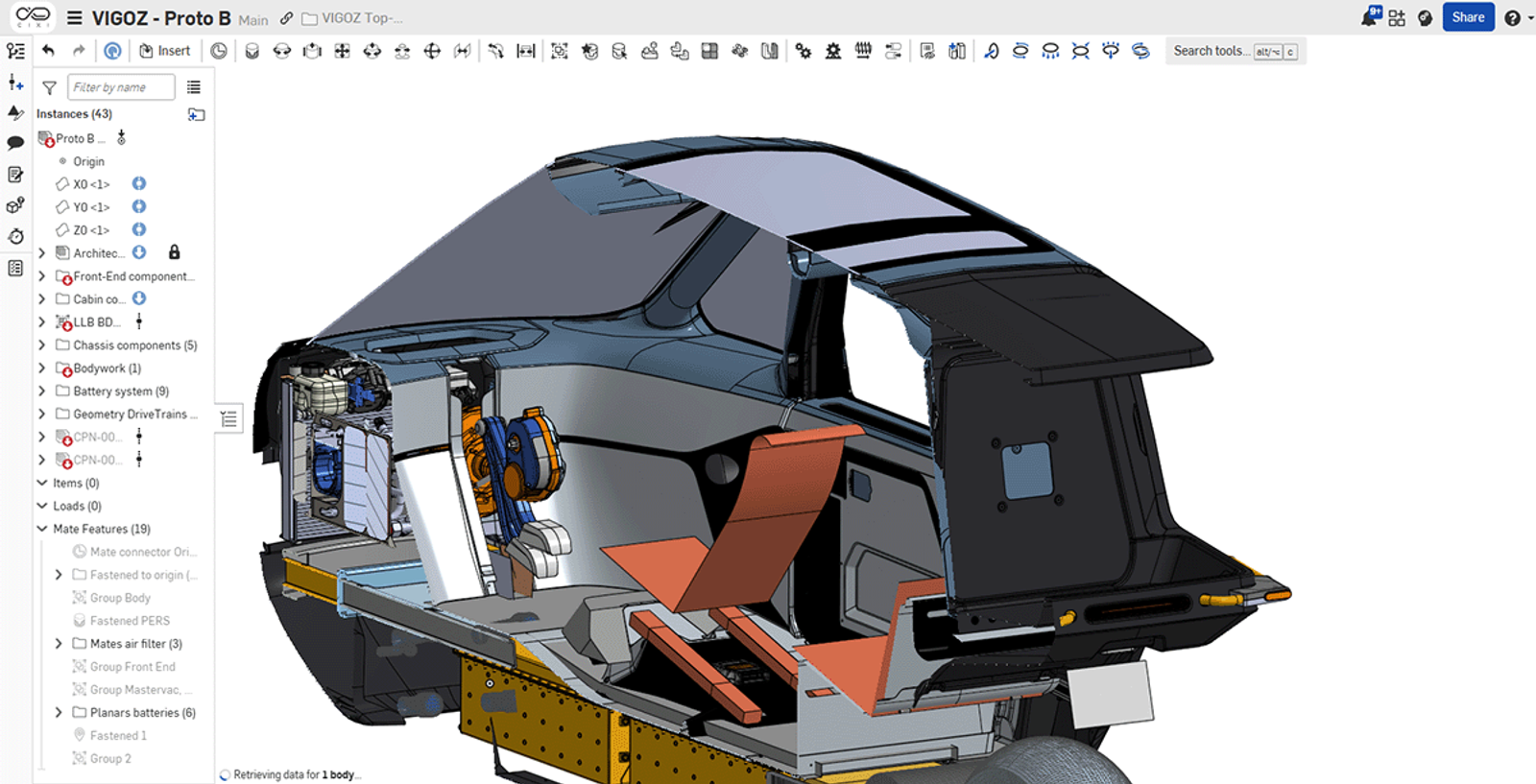

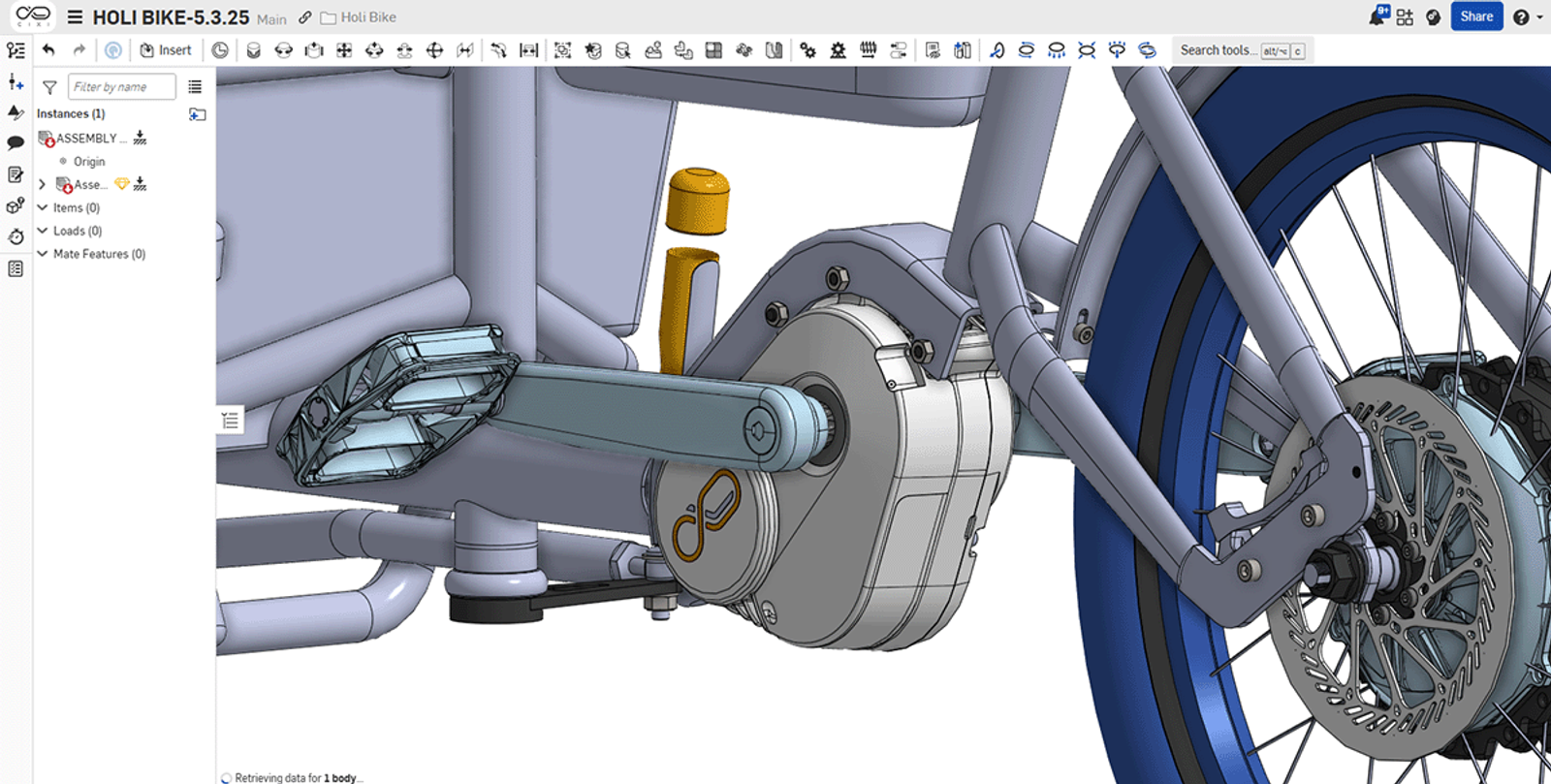

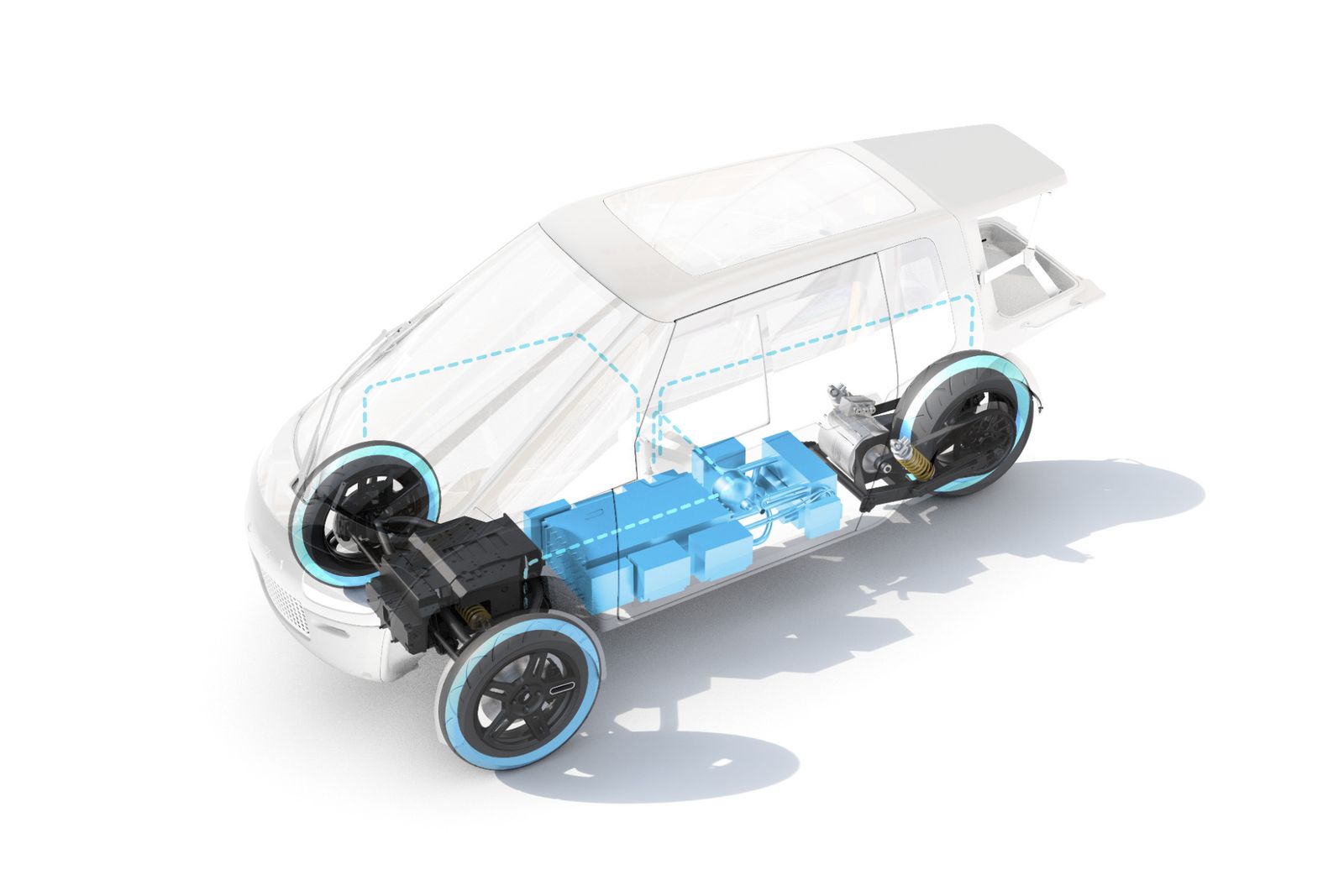

CIXI, a pioneering French mobility company, is setting out to redefine urban transportation with active mobility solutions. Their patented PERS chainless pedaling technology is integrated into high-speed active vehicles, blending cycling ergonomics with automotive-grade performance to encourage physical movement without requiring people to change their daily routines.

But as CIXI scaled development of their flagship innovations, their legacy CAD and PDM system, SOLIDWORKS, slowed progress. Engineers frequently lost work due to crashes or corrupted files, and performance issues meant they spent at least one hour per week simply waiting for models to load or regenerate. Check-in/check-out workflows routinely blocked collaboration across projects, causing engineers to overwrite each others’ work or unknowingly build on outdated designs. Managing versions and maintaining traceability became tedious and error-prone, especially as assemblies grew in complexity.

These mounting operational bottlenecks were compounded by the limitations of their local hardware. The team relied on high-end workstations just to maintain acceptable performance, yet still faced slowdowns, forced upgrades, and yearly downtime for software maintenance. Sharing files outside the engineering team was equally inefficient, requiring constant exports and manual file transfers.

As CIXI accelerated development and expanded into a fully digital product ecosystem, its CAD infrastructure could no longer support the pace, flexibility, or collaboration required. The search for a modern, scalable, cloud-native solution led them to PTC’s Onshape.

Results

- Cloud-native reliability saved 40+ hours per engineer annually by eliminating CAD downtime and crashes

- Streamlined the design iteration process with built-in PDM tools

- Reduced hardware costs by 75% without sacrificing speed or performance

- Simplified real-time collaboration, improving teamwork, accelerating decision-making, and aligning stakeholders

Onshape fits perfectly in our vision of numerical continuity. It gives us a clean, connected source of truth across our tools and teams.’’

Eliminating CAD Downtime & Crashes Saves 40+ Hours Annually Per Engineer

Before moving to cloud-native Onshape, CIXI’s engineering efficiency was tied closely to the performance of its on-premise workstations. CAD users spent nearly one hour each week simply waiting for file-based models to open, save, or reload; time that snowballed across the team and slowed project velocity. This not only disrupted the technical workflow but also eroded confidence and created a culture of caution, where engineers hesitated to push new ideas forward for fear of losing them.

With Onshape, design calculations happen instantly in the cloud, offloading the heavy lifting from local machines. This shift not only accelerates daily operations, but it also stabilizes them. Every action is saved instantly and securely in real time. Engineers no longer need to “save early, save often,” manage local backups, or fear losing momentum and ideas. The impact on CIXI’s productivity is immediate and compounding. Each engineer effectively gains 40–45 hours of design time each year that was previously lost to idle waiting.

“We don’t have crashes now, and loading times are basically nothing,” says CIXI mechanical engineer Thomas Lemaitre.

Fearless, Faster Iteration With Built-In PDM

CIXI’s products require extensive exploration of alternative geometries and mechanisms. Under their file-based system, versioning was difficult to manage, and branching was largely impractical.

Onshape’s built-in product-data management (PDM) tools changed this dynamic entirely. Engineers can now branch and merge designs freely, exploring multiple concepts side-by-side and comparing iterations quickly without duplicating files or losing track of ideas.

“Onshape’s versioning system lets us navigate between several branches or return to a previous version extremely easily and quickly compared to a file-based system,” says CEO and co-founder Pierre Francis.

This helps the team converge on optimal solutions sooner. They iterate designs more ambitiously with greater trust in their tools, which translates directly into higher-quality designs and more confident prototyping. The result is a more fluid, fearless approach to innovation that aligns naturally with CIXI’s culture.

Reducing Hardware Costs by 75% While Increasing CAD Accessibility

Under their previous system, CIXI was locked into using powerful, expensive desktop workstations often costing €2,000 or more per machine. These high-end setups struggled under the weight of large assemblies and regeneration cycles and required frequent maintenance, upgrades, or replacements.

Those headaches disappeared with Onshape. Engineers can now work effectively on lightweight laptops without compromising performance or speed for a fraction of the cost. CIXI reduced their hardware spend by 75% while improving accessibility for team members working remotely.

And because Onshape is fully cloud-native, there are no installations, no patches, and no yearly upgrades to plan for. CIXI is simply always up to date with the latest version. New features, improvements, and performance enhancements are pushed live every three weeks, with a total of 17 automatic releases per year.

“If you have to spend one week a year updating a full CAD system, you’re losing money,” says Lemaitre. “With our previous system, upgrading the software stopped our team from working. Now we just log in and it’s up to date.”

Streamlined Stakeholder Collaboration Boosts Team Efficiency

CIXI works closely with internal and external stakeholders, so sharing CAD data quickly and reliably is critical. In the past, design reviews were slow and logistically difficult, requiring file downloads and data transfers.

With Onshape, document access flows through simple permissions and shareable links. Non-CAD users can review designs in real time with view-only accounts, eliminating the need for exports or specialized software. Comments, tasks, and markup tools allow stakeholders to provide feedback that’s automatically tied to the correct version of the model.

“Design reviews are much more efficient [in Onshape],” Francis says. “Each stakeholder can open the design on their laptop, which helps with review preparation and reduces meeting time.”

This smoother, more integrated collaboration improves teamwork and ensures stakeholder alignment.

“Teamwork is very efficient thanks to real-time collaboration, and the comment and task system allows for very efficient work segmentation without designers stepping on each other’s toes,” Francis says.

Building Greater Digital Connectivity Through a Single Source of Truth

Onshape’s open integration (API) framework aligns with CIXI’s long-term goal of building a single source of truth across all of their departments and tools.

“We try to have single sources of data across the company,” explains CTO and co-founder Nicolas Ohlmann. “Onshape contributes to that with a clean database and seamless integration with our other tools.”

As the company expands its product lines and moves into new services, this unified data infrastructure ensures that information flows consistently and efficiently between teams.