07:07

Through a strategic partnership, Onshape, PTC's fully cloud-native CAD platform with built-in PDM, and SimScale, a powerful cloud-based simulation platform, have joined forces to transform how startup teams approach design and analysis. This collaboration makes comprehensive design and simulation – from structural analysis to fluid simulation and CFD – truly accessible directly through your web browser.

Everything Starts with a Design

How would an engineer approach a design problem? As an example, say your task is to equip an industrial warehouse with shelves, which need to accommodate 30 kg of payload. The shelves have to be thin and compact, not break or plastically deform under heavy loading, and demonstrate bending resistance so they won't fall off the mounts or interfere with the shelves below.

Using the traditional design approach, you would have to start with an existing design and figure out ways to make it thinner but still robust. You would rely on a structural analysis theory and material science to develop a few design iterations leading to a series of design candidates. Those candidates would then be manufactured before being tested and validated against real data. Such a process would likely have to be repeated multiple times until a satisfactory design is reached, which is both time-consuming and labor-intensive.

So, how could an engineer optimize their design process early on?

Onshape-SimScale: Cloud-Native CAD Meets Advanced Simulation

The partnership between Onshape and SimScale brings together the best of both worlds: Onshape Simulation provides the collaborative CAD foundation with integrated basic simulation capabilities, while SimScale delivers advanced simulation, including structural mechanics, heat transfer, and computational fluid dynamics (CFD) applications. This collaboration significantly accelerates the design process while making sophisticated simulation accessible to teams of all sizes.

At the CAD level, you can use Onshape to bring up any existing design from your library and begin implementing changes with your team right in your web browser. For instance, once you come up with an initial design, you can share a link to it with the rest of your team so everyone can inspect and suggest improvements. With Onshape's cloud-native platform, everything is readily available and can be accessed from anywhere.

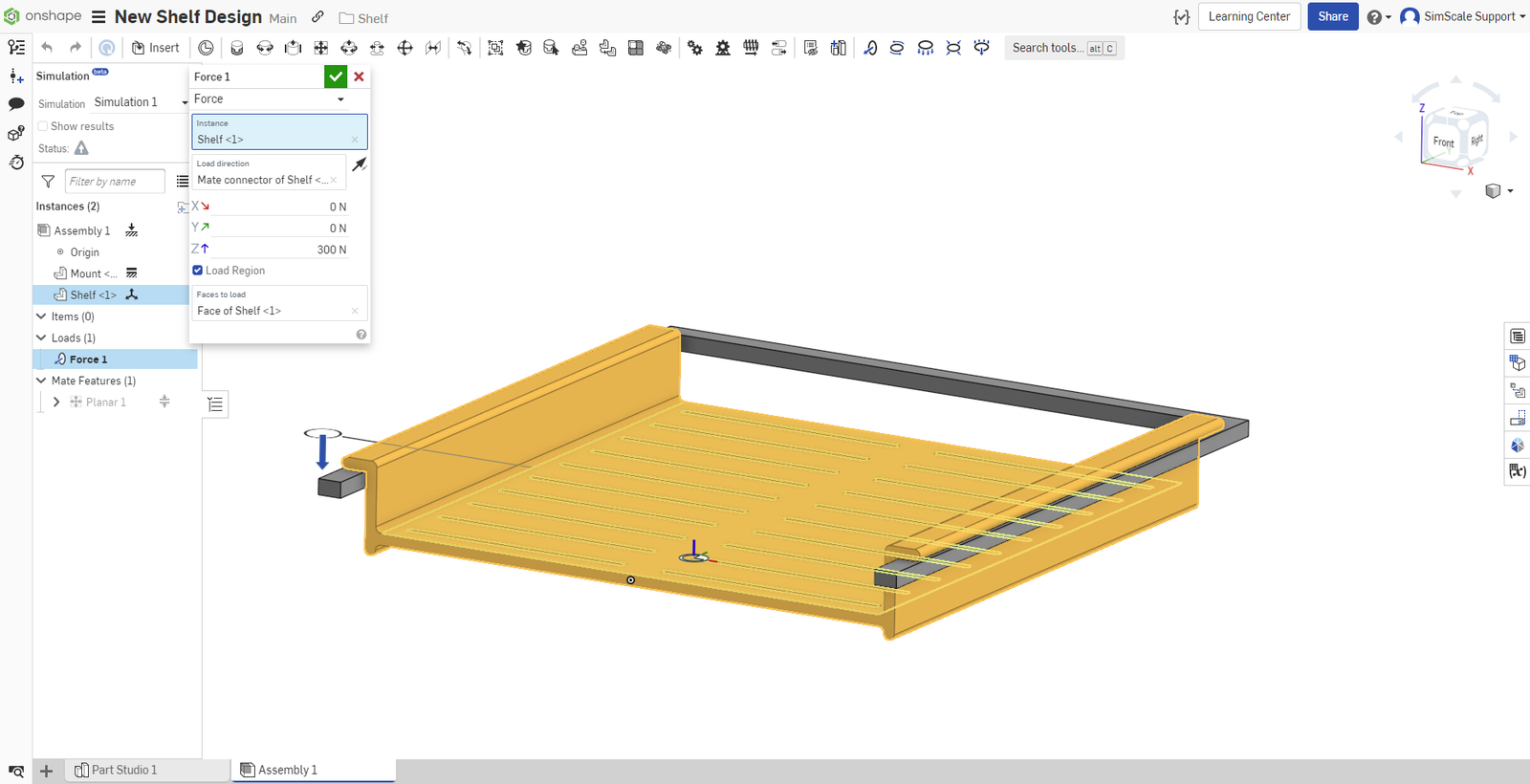

By the time you have your design ready for testing, you'd probably start thinking about building prototypes. However, prior to that, you can run quick FEA simulations inside Onshape to test your design virtually simply by switching tabs on your web browser.

Figure 1: Onshape Simulation setup.

Via a quick and intuitive setup, you can take advantage of Onshape's built-in simulation capabilities and gain valuable design insights. Within seconds, you can immediately see the most sensitive areas of your design. In our example, the simulation results in Figure 2 show that the central part of the shelf is massively deforming by 3 mm, which is already 60% of its thickness.

Figure 2: Onshape Simulation results show shelf deformation.

There might be several reasons why this might be happening. Onshape has a pre-populated material library allowing the team to check and compare different materials with different mechanical properties quickly. You can simply change the material assignment and instantly see how this affects the deformation.

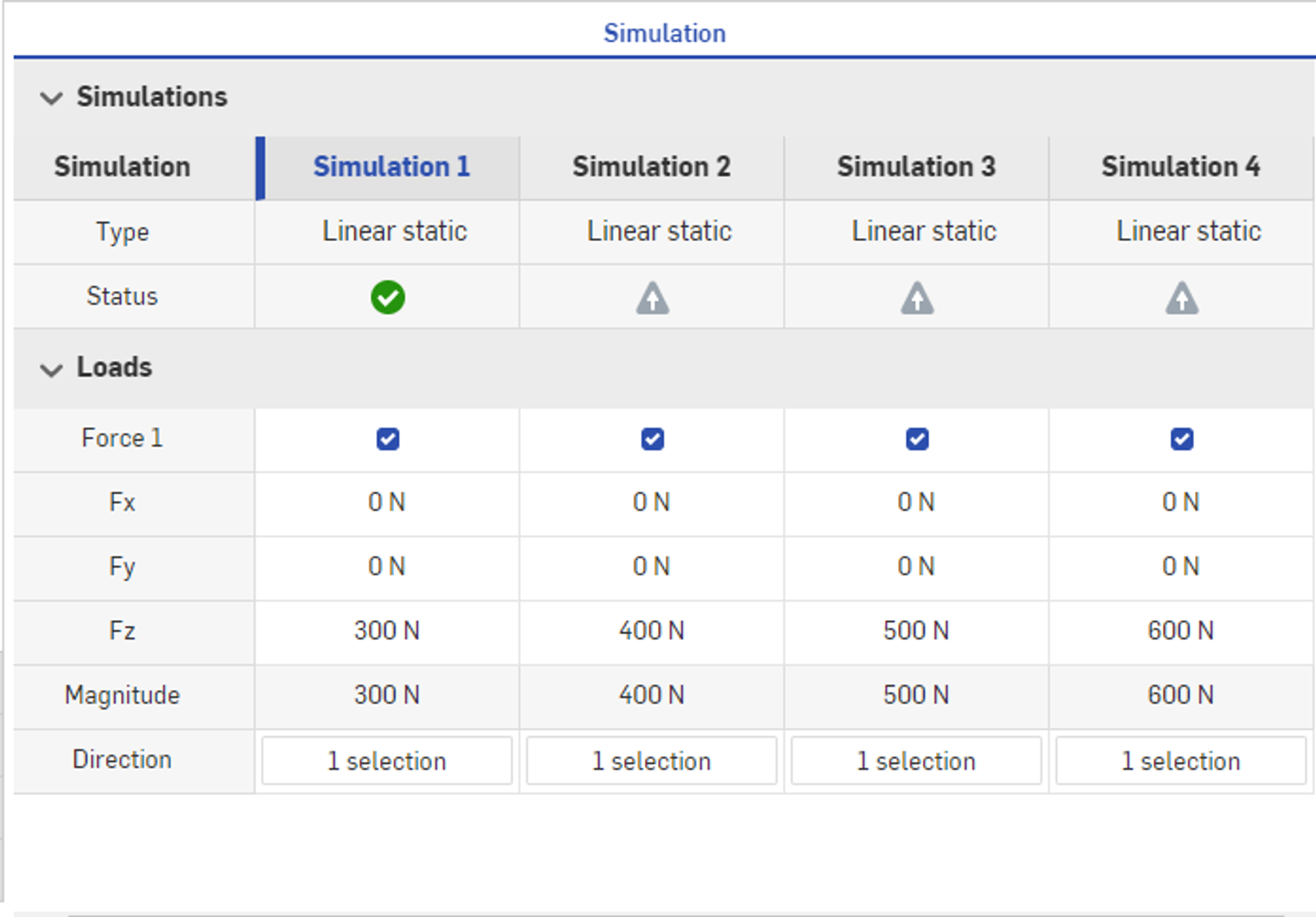

You can also run multiple studies by progressively increasing the shelf loading to study what might happen if the shelf is accidentally loaded by more than the designated weight it was designed to hold.

Figure 3: Onshape Simulation panel is running multiple simulations.

But what really makes Onshape's integrated simulation stand out is the speed and efficiency of applying geometrical design changes to the model simply by switching browser tabs. Going back to the Part Studio tab, you can easily modify any design feature, such as increasing shelf thickness, changing its shape, and adding supporting ribs. You can then submit the changes, revert back to the simulation tab, and within seconds, see the updated results according to the applied changes.

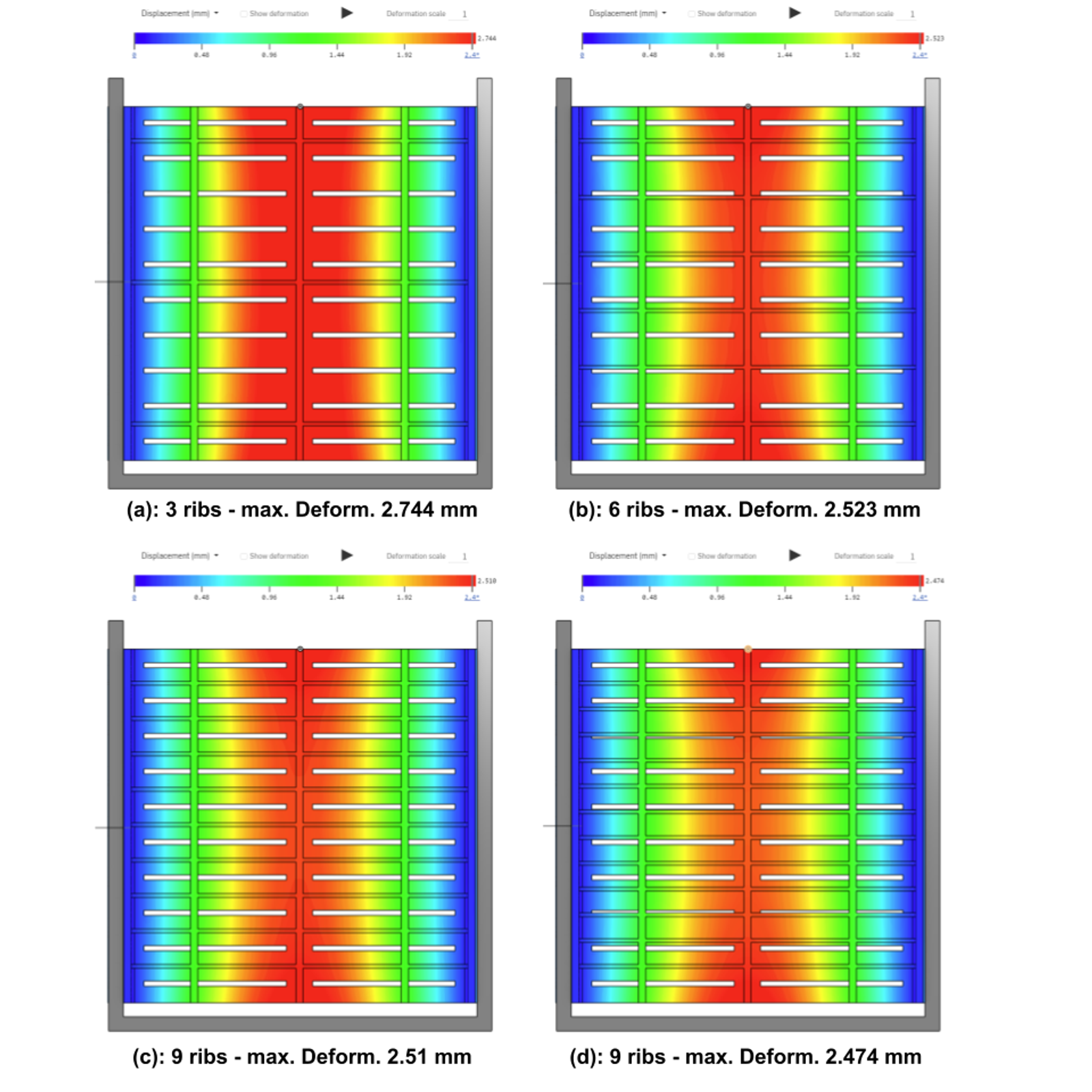

In this particular example, you can add extra support ribs to reduce the maximum deformation and prevent failure in case of overloading. Of course, in such cases, it's important to keep the total mass of the model as low as possible to reduce material costs. For that, you can develop a parametric approach in Onshape to adjust the total number of ribs and run a series of simulations to check the maximum deformation, like in the example below.

Figure 4: Quick comparison of four alternative designs of rib supports to minimize deformation.

Based on these results, adding nine ribs seems sufficient to increase the new design's stiffness and help it withstand failure in cases of overloading.

The same process can be repeated for any other geometric feature, material properties, and loading conditions. Onshape's built-in simulation is a suitable tool for fast design iterations and efficient trend analysis.

Advanced Simulation with SimScale: CFD, FEA, and Thermal Analysis

By now, you'd have checked several alternative configurations, tested different material properties, and benchmarked the new shelf design under different loading conditions. Using Onshape's initial simulation capabilities, you can select a couple of high-potential designs and seamlessly transition to SimScale to unlock advanced simulation capabilities including computational fluid dynamics (CFD), high-fidelity structural analysis, and thermal simulation – all while working in your web browser.

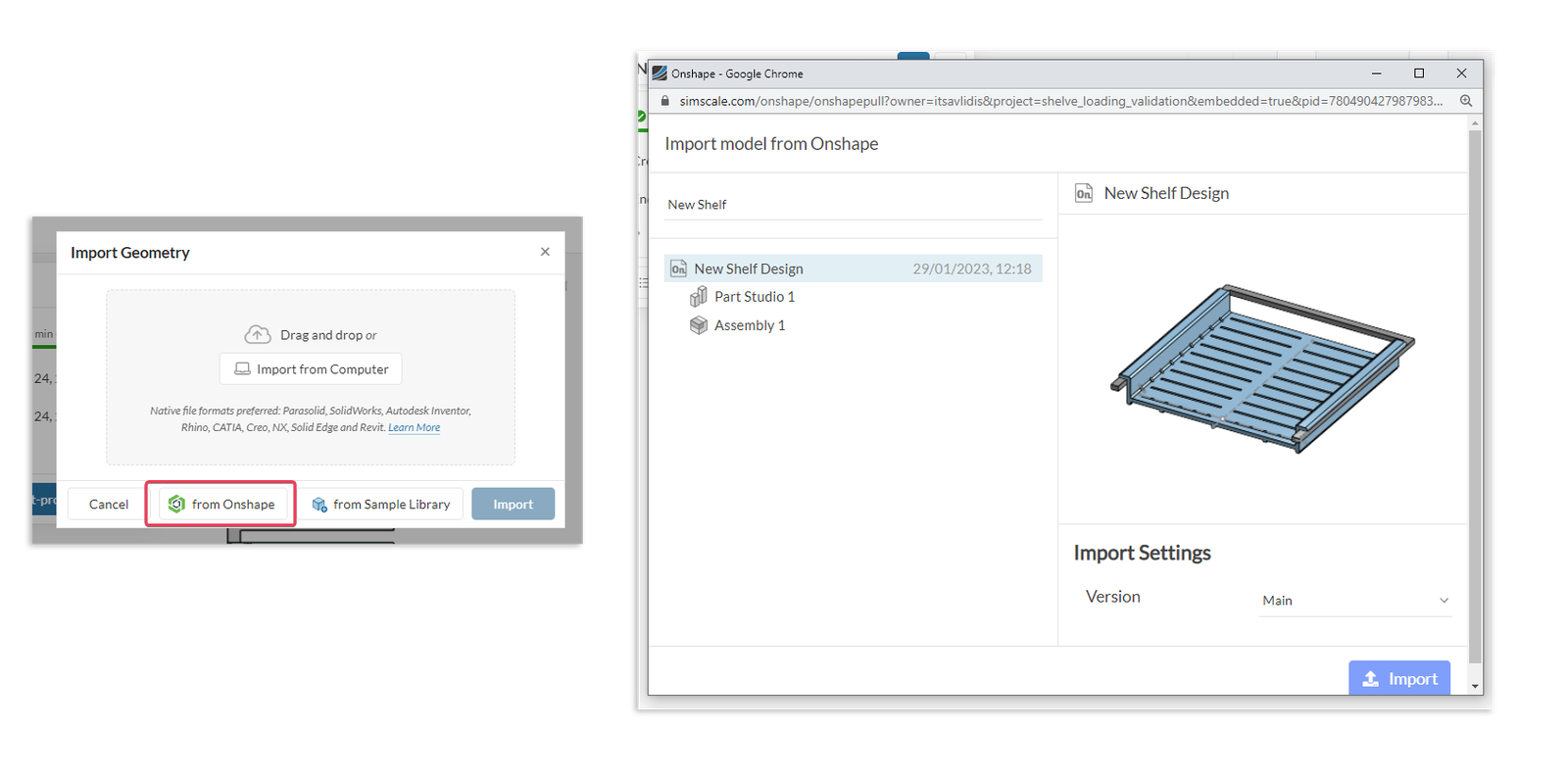

Through the partnership, designs can be easily imported from Onshape to SimScale via the dedicated geometry import plug-in, creating a seamless workflow between CAD and advanced simulation.

Figure 5: Import directly from Onshape to SimScale via the available plug-in.

In SimScale, users can add significantly higher fidelity to their qualified models and access simulation types not available in basic CAD packages. Here are some examples of SimScale's advanced capabilities:

- Higher Accuracy with 2nd-Order Elements: Capture curved geometry and stress gradients more precisely with quadratic elements.

- Smarter Meshing with Symmetry: Apply symmetry to reduce model size and boost mesh density where it counts.

- Realistic Contact Simulation: Model separation and friction to reflect real-world part interactions.

- Advanced Material Models: Simulate plastic deformation and rubber-like stretch with elasto-plastic and hyperelastic models.

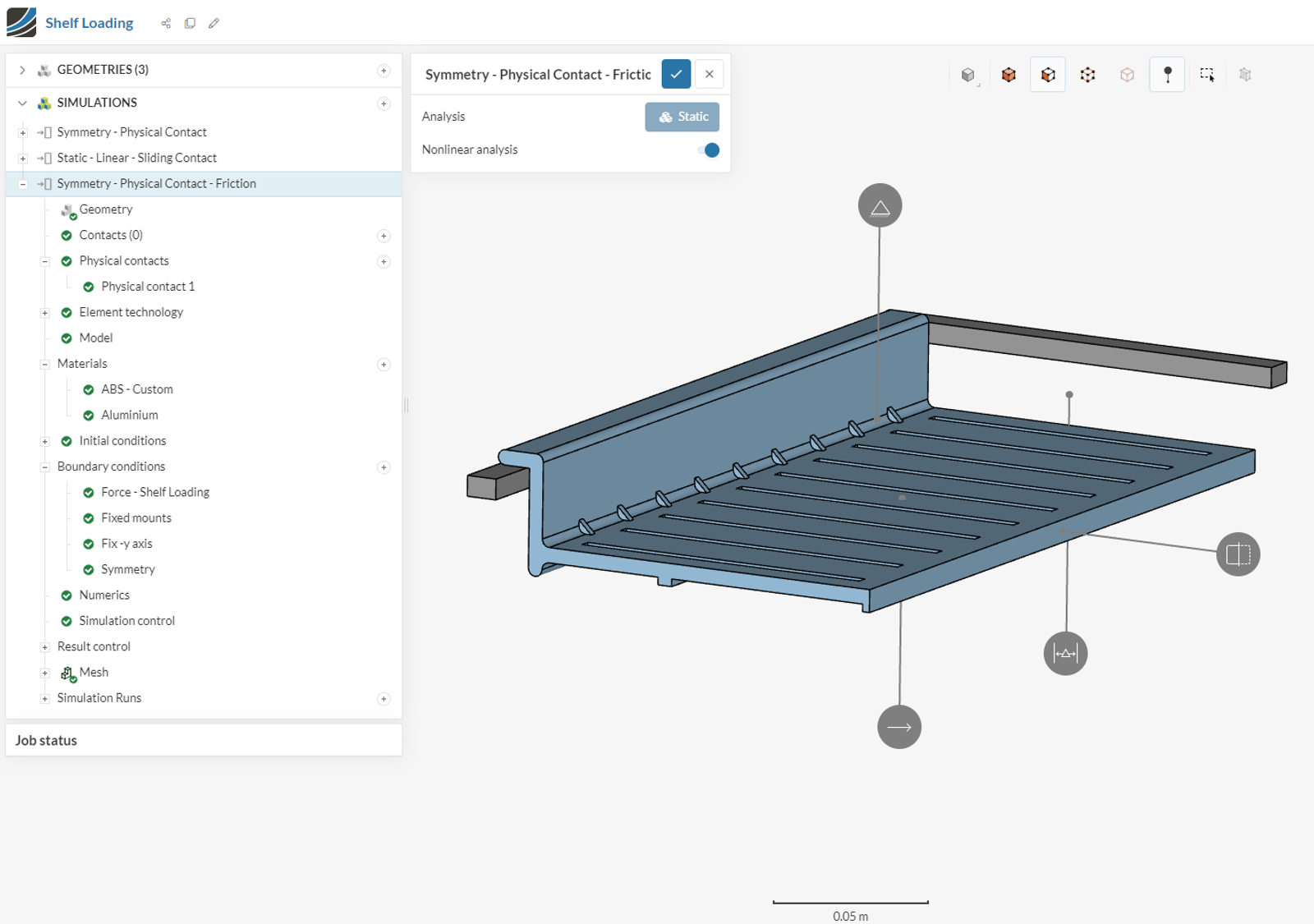

For structural analysis, modeling the physical contact between the shelf and the mounts is crucial; excessive bending might lead the shelf to fall off the mounts, and the equipment might get damaged.

The model can be split in half, using the symmetry boundary condition, increasing the total mesh node count to improve accuracy. Using 2nd-order mesh elements and utilizing mesh refinements on regions of particular interest also add to the final accuracy, especially when it comes to bending behavior.

Figure 6: The simulation tree/setup in SimScale.

Checking the deformation results, you can identify the actual maximum deflection of the shelf (~ 11 mm). It also appears that increasing the overall load of the shelf is likely to lead to it falling off the mounts as already 30 kg are causing it to bend and separate quite excessively.

Figure 7: A high-fidelity shelf bending simulation in SimScale.

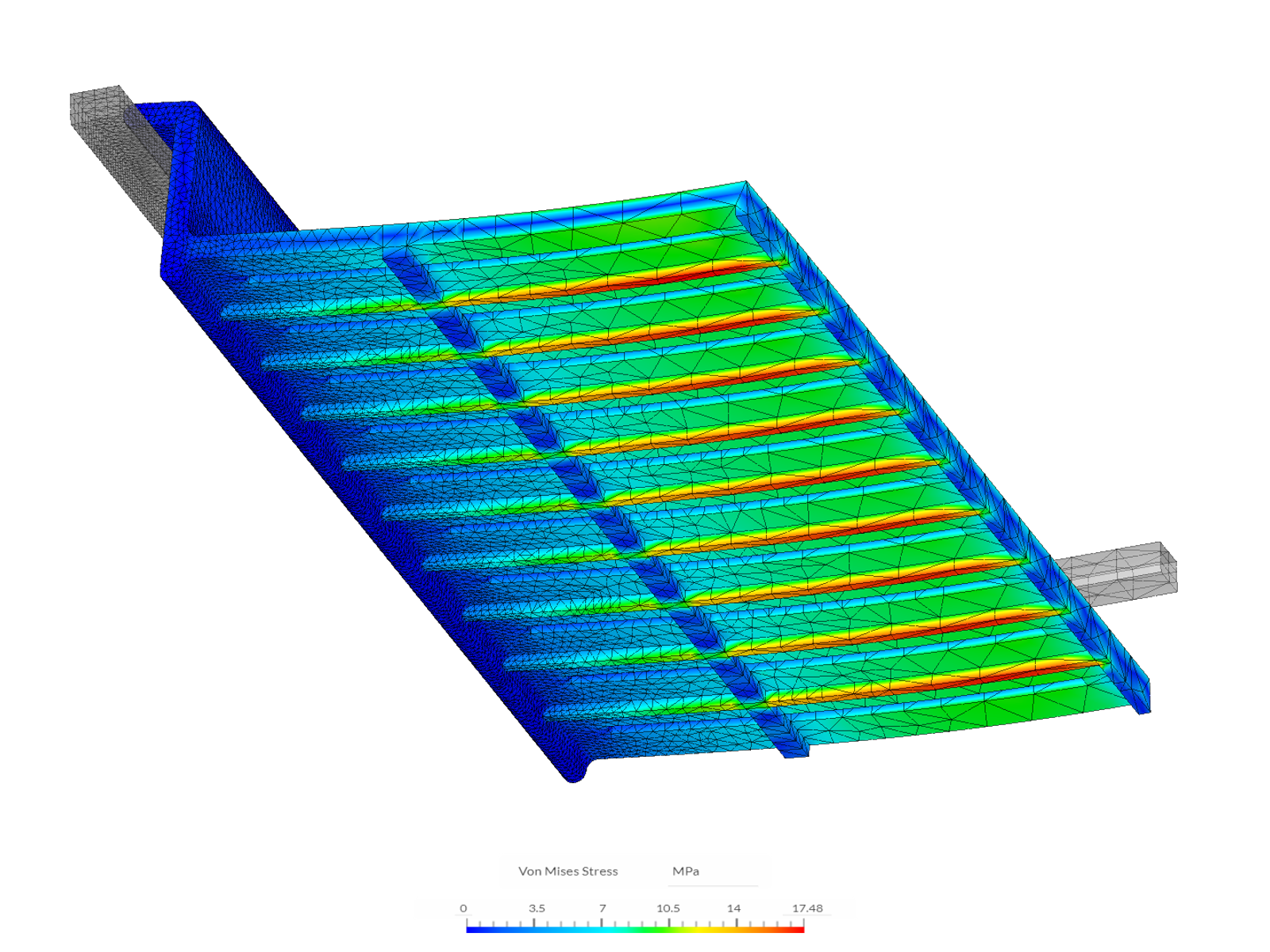

You can also visualize the maximum developed stresses by inspecting the Von Mises Stresses of the model. In our example, the maximum occurring stress seems to be 17.48 MPa. Keep an eye, however, on the material used (e.g., ABS thermoplastic polymer). Commercial ABS material might come in different compositions, affecting its mechanical properties.

Figure 8: An example of Von Mises Stress plot of shelf loading.

A Complete Simulation-Informed Design Process Through Partnership

The Onshape-SimScale partnership creates a comprehensive simulation-informed design workflow that leverages the strengths of both platforms. Onshape provides the collaborative CAD foundation with integrated basic simulation for rapid design iteration, while SimScale delivers advanced simulation capabilities including CFD, high-fidelity FEA, and thermal analysis for detailed validation and optimization.

With a few clicks in Onshape, you can switch from drawing to simulation and evaluate your designs with built-in FEA capabilities. You can then switch back to CAD, rapidly implement any design changes and re-evaluate them within the same environment by simply switching tabs. This helps develop an initial simulation-informed design process, drastically speeding up the whole design cycle and the generation of high-potential design candidates.

These design candidates can then be seamlessly transferred to SimScale for increased simulation fidelity and access to advanced analysis types including:

- Computational Fluid Dynamics (CFD) for analyzing fluid flow, pressure distributions, and aerodynamic performance

- Advanced Structural Analysis with geometrical, material, and contact non-linearities

- Thermal Simulation for heat transfer and thermal stress analysis

- Multiphysics Simulations combining multiple physics phenomena

This partnership helps enrich the design process with comprehensive trend analysis driven by parallel cloud computation, sparking innovation and providing deep insights into the mechanical and fluid dynamic performance of products. It also helps validate decisions with physical test replication through the web browser.

Supporting the Next Generation of Engineers

Through their strategic collaboration, Onshape and SimScale are committed to democratizing access to powerful design and simulation technology. The partnership includes special programs for start-ups and educational institutions, ensuring that the next generation of engineers has access to professional-grade tools regardless of their organization's size or budget.

You can explore the complete Onshape-SimScale workflow by checking out the SimScale project setup and results of the shelf design example by creating a free account today. Experience firsthand how this powerful partnership combines collaborative CAD with advanced simulation capabilities, including CFD, structural analysis, and thermal simulation – all accessible directly through your web browser.

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and real-time collaboration in one system.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more