The Challenge

Transporting critical cargo like medical supplies, emergency equipment, and time-sensitive goods typically relies on airplanes and helicopters. While effective, these aircraft are expensive to operate, complex to maintain, and often impractical for remote or underserved regions. They require onboard crews, extensive ground infrastructure, and favorable operating conditions, all of which increase cost and risk.

Swiss-based Dufour Aerospace envisioned a new solution: long-range hybrid-electric uncrewed drones capable of flying hundreds of kilometers while carrying substantial payloads and advanced sensor systems. These drones take off and land like helicopters but deliver the speed, efficiency, and safety of airplanes. This makes them an ideal solution for real-world critical cargo delivery with high safety standards and low operating costs.

Dufour’s product-development cycles require tight integration between software, hardware, structures, and certification requirements. In early years, they relied on a patchwork of manual processes and disconnected tools to manage design data, part numbers, and releases. Manual exports, spreadsheet-based workflows, and fragmented communication between design and manufacturing created friction as the team grew and projects became more complex.

“It’s about bringing all the disciplines together, from software engineering to hardware, and managing it so everything fits together,” says Dufour CEO Sascha Hardegger.

As Dufour grew into a full-fledged aerospace OEM, Dufour needed a modern, cloud-native design and data-management platform that could scale with its ambitions. They chose PTC’s Onshape CAD+PDM and Arena PLM to achieve these outcomes.

Results

- Saved approximately $100,000 annually in CAD licensing and infrastructure costs

- Enabled faster iteration on complex aerospace systems with Onshape’s real-time collaboration and data management tools

- Reduced design data requests from manufacturing teams by 50% thanks to the Onshape-Arena Connection

- Saved up to 8 hours of engineering time per part release due to automated design handoffs

As an aerospace startup transitioning to a proper design organization, having tools that allow us to communicate our design data in a controlled manner is crucial. The combination of Onshape and Arena lets us make this transition smoothly, stay agile, and deliver complex drones that meet customer needs.’’

Reducing CAD Licensing & Infrastructure Costs by $100,000 Annually

On-premise legacy CAD systems often require expensive licenses, powerful local workstations, and complex IT infrastructure. These costs scale quickly as teams grow and access expands beyond core design roles. Onshape’s simplified licensing plans have delivered substantial cost savings for Dufour Aerospace.

Based on internal analysis, Dufour estimates that adopting Onshape saves them approximately $100,000 per year in CAD licensing and infrastructure costs compared to traditional CAD systems. Onshape allows Dufour to provide appropriate CAD access across the organization without over-provisioning full licenses.

Engineers design in the same cloud-based environment that manufacturing, quality, and supply chain teams use to review models and drawings. Any Onshape user can access designs from their standard work laptop, phone, or tablet, eliminating the need for expensive workstations (and accompanying IT overhead) that legacy CAD systems require no matter what level of access a user needs.

These savings support continued investment in engineering innovation while maintaining a scalable, cost-effective digital foundation.

Accelerating Aerospace Design with Cloud-Native Onshape

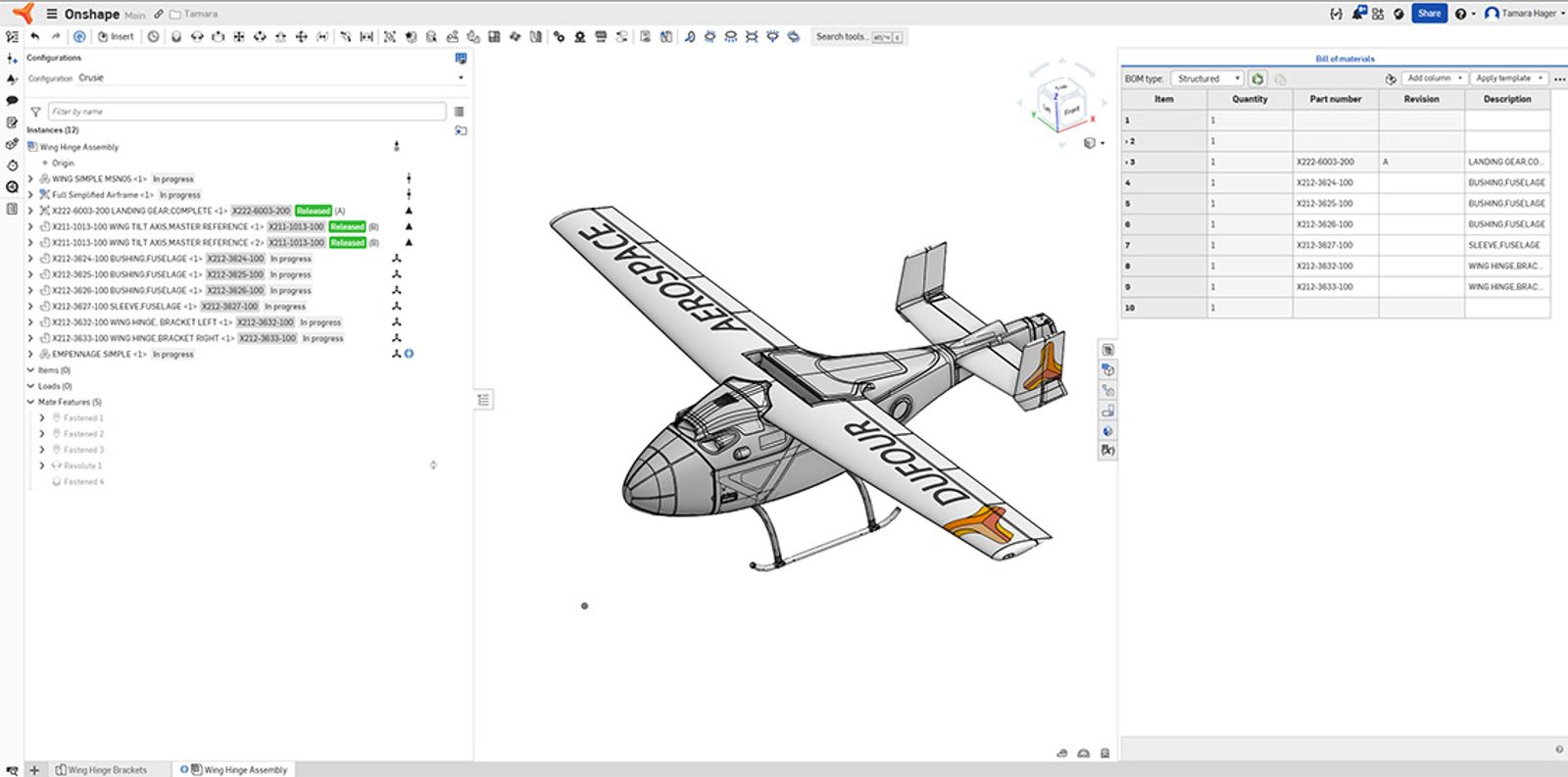

Dufour Aerospace adopted Onshape to support the fast, iterative development cycles required for their uncrewed drones. The cloud-native CAD and PDM platform enables engineers to design complex, multi-part systems in a single environment, with parts created in context and assemblies validated early through direct clearance and interface checks.

Available 24/7 through any web browser, Onshape allows team members to collaborate simultaneously from any device and location in real time. Onshape eliminates file-based CAD check-in/check-out workflows, so it’s easy to share designs, review changes, and resolve issues without downloads, file transfers, or local hardware installations.

“You can work from different locations, open the same design, and discuss it together in real time,” says Tamara Hager, Design Team Lead. “With Follow Mode, it really feels like you’re in the same room.”

Thanks to Onshape’s built-in product-data management, automatic versioning and revision history allow engineers to explore design alternatives confidently, knowing that changes are fully traceable and recoverable.

“You can see which parts are released, what the status is, and there’s built-in traceability so everyone is aware of changes,” says Hager. “Even if there’s a new version, you can see exactly what changed. That’s extremely important for versioning and avoiding errors.”

These capabilities support critical requirements for aerospace development like early validation, rapid iteration, and disciplined configuration control.

Streamlining Manufacturing and Supplier Collaboration with Onshape and Arena

Before adopting the Onshape-Arena Connection, Dufour’s manufacturing teams often depended on design engineers to locate drawings, confirm revisions, or explain interfaces. As the business scaled, the volume and complexity of these requests increased significantly, creating frequent interruptions and slowing both teams.

With cloud-native Onshape, Dufour established a shared, single source of truth for design data. By integrating that design data with Arena PLM, engineers, manufacturing, and suppliers can access the same up-to-date models, assemblies, and released drawings instantly without relying on file transfers or access from other teams.

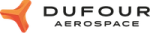

“Since we introduced Arena, manufacturing doesn’t call us anymore to find drawings,” says Manuel Flepp, Head of Structures. “They can usually find what they need themselves, and if not, we just share a link.”

As a result, Dufour estimates that design data requests and communication between engineering and manufacturing teams have been reduced by about 50%. Engineers remain focused on design and development, while manufacturing teams gain faster access to accurate information, streamlining collaboration across the organization.

Saving Up to 8 Hours Per Part Release Through Automated Data Management

Before Arena, Dufour’s engineers manually generated part numbers using Excel spreadsheets, exported drawings and 3D models, and then distributed files to suppliers through external cloud storage vendors. These workflows consumed valuable engineering time and created opportunities for errors.

By connecting Onshape directly with Arena, Dufour automated the part-release process. Part numbers are generated and synchronized automatically, and released parts and drawings are transferred directly into Arena without additional effort from the design team. Bills of materials (BOMs) are created and maintained in a single, authoritative system, ensuring consistency across engineering, manufacturing, and the supply chain.

“We use Onshape in our everyday design workflow and Arena when we release a part for manufacturing. At that moment, parts and drawings get synchronized to Arena and shared in a controlled manner with the supply chain,” explains Flepp.

This automated workflow saves two to three hours per release by eliminating manual part number management, and an additional three to five hours per release by removing the need for manual data distribution to suppliers. Combined, Dufour saves up to 8 hours per part release, allowing engineers to focus on product development rather than administrative tasks.

Onshape and Arena: A Strong Digital Foundation for Aerospace Innovation

Dufour Aerospace’s mission to deliver reliable, long-range uncrewed drones for critical logistics and sensor missions depends on speed, precision, and trust in its design data. By adopting Onshape and connecting it with Arena, the company has built a digital foundation that supports collaboration, traceability, and controlled growth.

The result is a development environment that allows Dufour to move quickly, supporting its evolution to a mature aerospace design organization capable of delivering safe, certified drones for real-world applications.