07:52

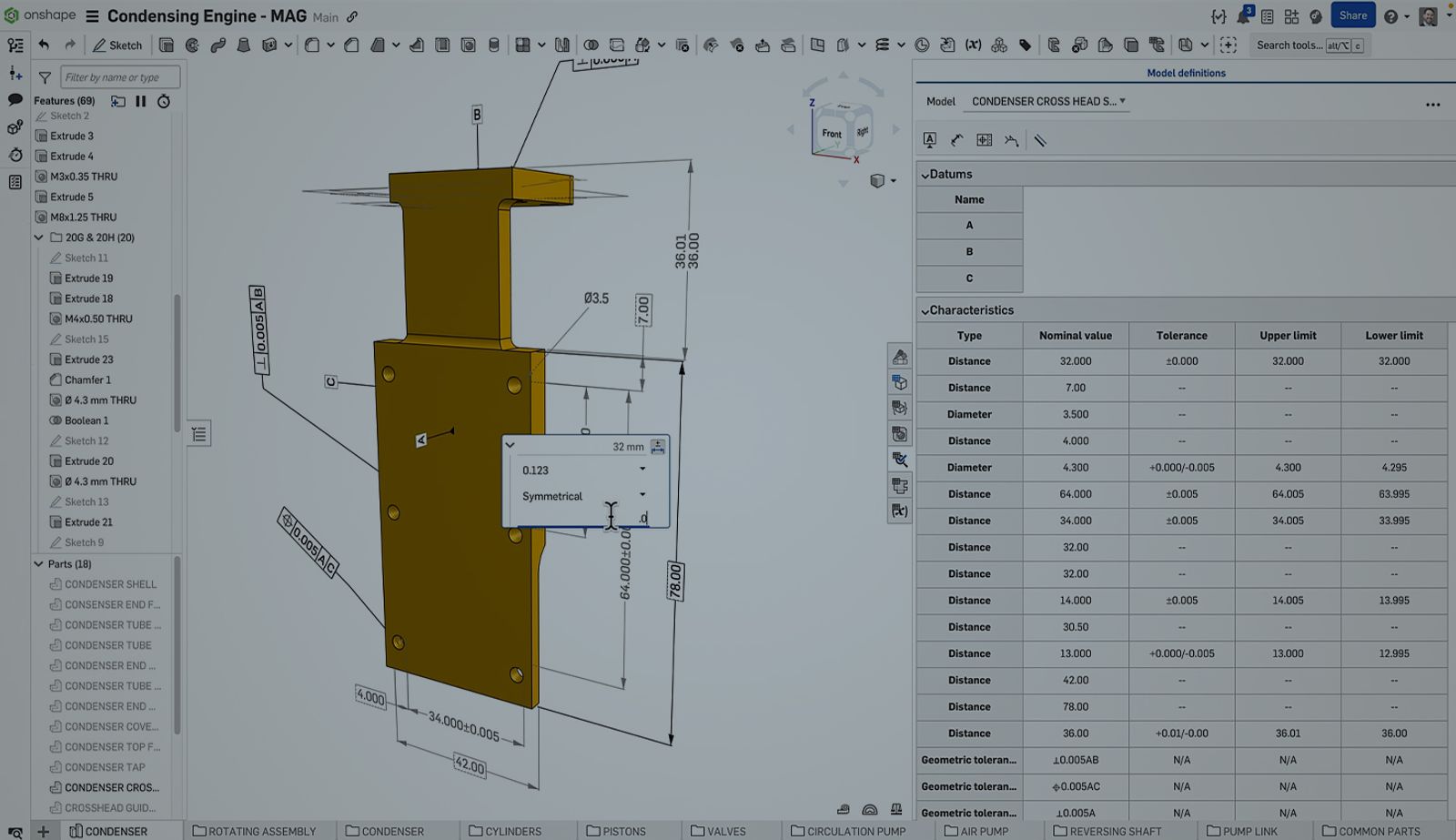

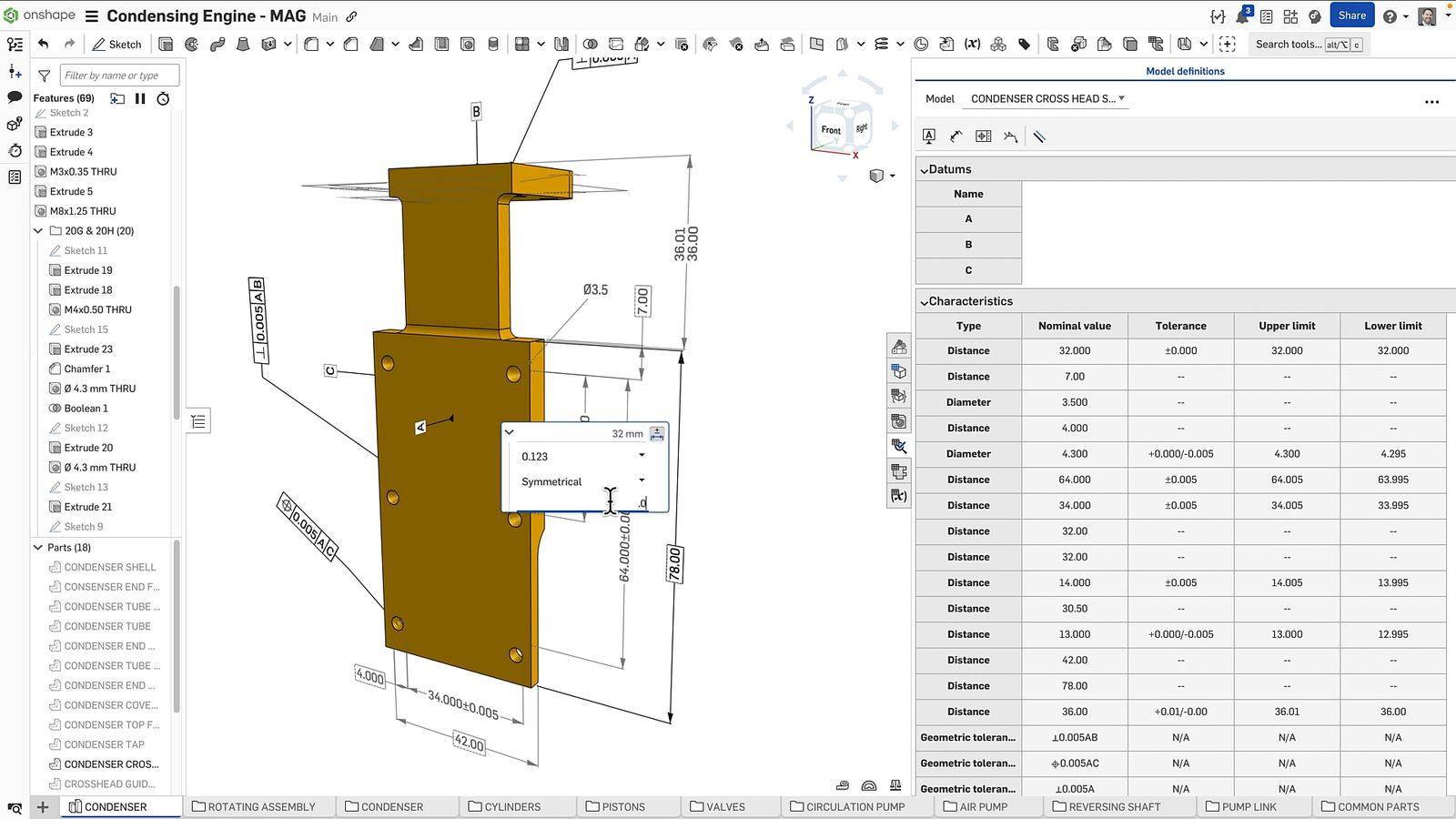

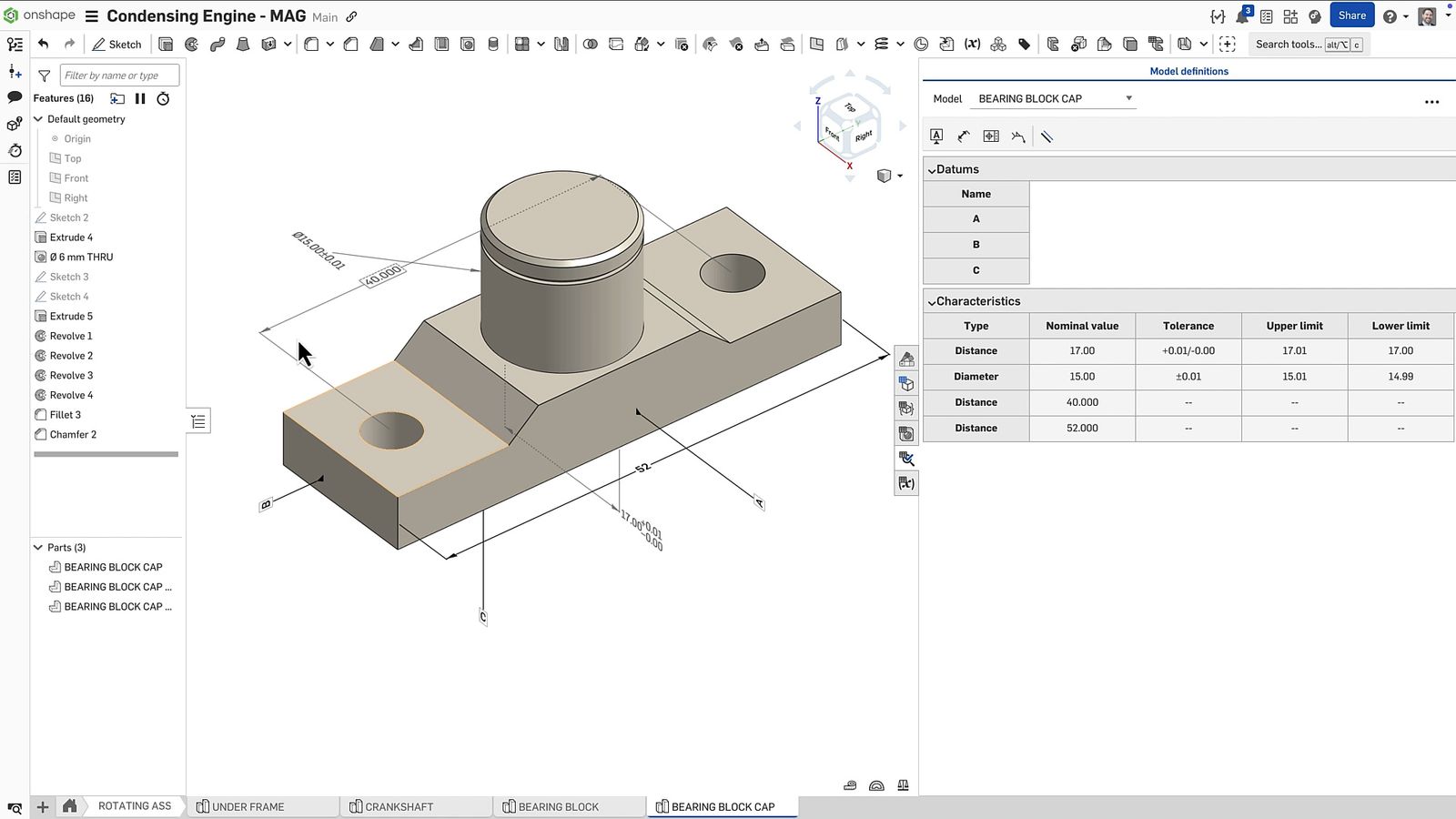

Ask any modern engineer or product designer what the source of truth is for their design, and they’ll most likely point to the 3D CAD model.

It’s ironic, then, that critical dimensions, tolerances, and manufacturing details are often found only in the 2D drawing. More and more teams are recognizing the value of bringing this crucial information into the 3D model itself.

This approach, known as Model-Based Definition (MBD), embeds manufacturing intent directly into the model earlier in the design process — enabling better communication with stakeholders, reducing errors, and streamlining downstream processes like CAM, inspection, and even detailed drawing creation. All of it flows from a single, authoritative source.

What is Model-Based Definition?

Model-Based Definition (MBD) is a method of creating a complete digital definition of a product within the 3D CAD model itself. Instead of relying solely on separate 2D drawings, MBD includes much of the necessary dimensions, tolerances, annotations, and other product manufacturing information (PMI) directly on the model.

With MBD, your 3D model becomes the go-to source of manufacturing information. It captures not only geometry but also the intent for how the product should be manufactured, inspected, and assembled.

Common MBD elements include:

- Dimensions and tolerances

- Geometric Dimensioning and Tolerancing (GD&T)

- Datums

- Annotations and notes

- Surface finishes

- Material specifications

Bills of Materials (BOMs) and other assembly-related information also need to be accessible with the model. This integrated approach reduces misinterpretation, minimizes duplication of effort, and helps ensure consistency across the design and manufacturing processes.

Why Engineering Teams are Moving to MBD

The advantages of adopting Model-Based Definition are becoming increasingly clear across engineering and manufacturing disciplines:

- Accelerated time to manufacturing: MBD shortens the time and resources needed to create, update, and maintain separate 2D drawings, enabling teams to move from design to production faster.

- Fewer errors: MBD reduces the risk of human error from misreading 2D drawings, which are often harder to interpret, especially with complex geometry or tight tolerances. MBD presents necessary information directly in the 3D model, ensuring clarity and consistency across teams, as well as minimizing duplication of critical dimensions in multiple places.

- Improved collaboration: MBD aligns design, manufacturing, and quality teams around a single, always-current model.

- Better compliance: MBD strengthens traceability and audit readiness, which is especially important in regulated industries. Because it requires all stakeholders to access and work from the same digital model, it inherently improves data consistency and ensures everyone is referencing the latest approved information.

- Increased automation: MBD enables downstream tools such as CAM, CMM inspection, and PLM systems to access all relevant product data directly from the 3D model.

For regulated or high-precision industries, MBD isn't just a modern best practice — it's rapidly becoming essential to digital transformation strategies.

Key Terms Associated with MBD

Understanding MBD also means becoming familiar with several related terms and standards:

- PMI (Product Manufacturing Information): All non-geometric data needed to manufacture a part, including dimensions, tolerances, notes, and material specs.

- GD&T (Geometric Dimensioning and Tolerancing) and Datums: A symbolic language that defines allowable variation in geometry, crucial for quality control.

- 3D Annotations: Notes, symbols, and dimensions added directly to the 3D model rather than in a separate 2D drawing.

- STEP AP 242: A neutral file format that supports MBD data and is designed for long-term archiving and interoperability.

MBD vs. MBE

MBD and MBE are often used interchangeably, but they refer to different scopes:

MBD | Model-Based Definition refers specifically to embedding PMI in the 3D CAD model. |

MBE | Model-Based Enterprise describes the larger organizational initiative where the annotated 3D model drives all downstream processes, including manufacturing, procurement, and quality. |

MBD

Model-Based Definition refers specifically to embedding PMI in the 3D CAD model.

MBE

Model-Based Enterprise describes the larger organizational initiative where the annotated 3D model drives all downstream processes, including manufacturing, procurement, and quality.

Think of MBD as a key enabler of the broader MBE vision.

Barriers to MBD Adoption

Despite the clear benefits of Model-Based Definition, adoption has been slower than expected in many organizations. The reasons are often less about the technology itself and more about long-standing habits, infrastructure, and cost considerations:

- Cultural inertia: 2D drawings are deeply entrenched in traditional engineering workflows. For many teams, the creation of a drawing is viewed as the official step that defines a "complete" design.

- Limited digital access on the shop floor: In many manufacturing environments, not every area is equipped with a device capable of viewing 3D models. Printed 2D drawings persist because they remain the most accessible and easily distributed format.

- Viewer and format limitations: Historically, viewing, and marking up MBD data outside of the native CAD application has required additional tools — such as lightweight viewers or specialized file formats like 3D PDFs. While intended to make model access easier, these secondary formats can quickly fall out of sync with the source model, adding complexity and undermining trust in the data.

- Cost of access: Traditional CAD licensing models often make it expensive to extend access to non-engineering roles. When only a few people can view or interact with the MBD data, the benefits of a model-based approach are diluted.

- Poor integration in design workflows: In many systems, MBD is treated as a separate capability rather than an integral part of the design process. As a result, applying MBD can feel like an extra step that is cumbersome and disconnected from the core modeling workflow.

Overcoming these barriers is key to unlocking the true value of MBD — and it's where modern, cloud-native solutions begin to make a meaningful difference.

The Role of Cloud-Native Technology in MBD Success

Model-Based Definition has been around for years, but its adoption has been slowed by the limitations of traditional file-based CAD and PDM systems. These systems make it difficult to ensure everyone is working from the same version of the model and can introduce friction when collaborating across departments or with external partners.

This is where cloud-native platforms like Onshape come in.

By eliminating files and enabling real-time collaboration, Onshape removes many of the barriers to successful MBD implementation:

- Access from any device: Whether you're in the office, on the shop floor, or working remotely, the full 3D model with all annotations is available in a browser. Inexpensive tablets, smartphones, and Chromebooks make it practical and affordable to bring 3D access to more places than ever before.

- A single source of truth: There are no file copies, check-in/check-out processes, or sync delays. Everyone sees the live, authoritative version of the model.

- No additional viewers or CAD installs required: Stakeholders across your organization and supply chain can interact with MBD data in a browser without needing CAD licenses or IT support. Lightweight licensing options also make it affordable to enable access for the entire enterprise — even for users who only need to view the data.

- Built-in version control and history: Every change is recorded, enabling traceability and compliance without additional effort.

With tools like Onshape, your team can accelerate its transition to MBD and unlock its full benefits — without increasing complexity or overhead. Learn about the next generation of MBD coming to Onshape soon.

The Potential of Cloud-Native Technology in MBD Success

While MBD offers clear benefits, its full potential is often constrained by the limitations of traditional, file-based CAD systems. These tools were never designed to support a truly integrated, real-time model definition workflow — especially across distributed teams and systems.

Cloud-native platforms like Onshape represent a significant opportunity to remove these limitations. Although full MBD capabilities are currently in development, the foundation is already in place to support a seamless and scalable approach:

- Unified access to a single model: A shared, always up-to-date model helps ensure every stakeholder is working from the same definition without needing file transfers or version reconciliation.

- Cross-platform availability: Any device, any time — whether on the shop floor or in a supplier’s office.

- Lightweight licensing for viewers: Makes it possible to enable the entire enterprise, from engineers to quality inspectors to procurement, without bloating IT costs or needing to install any separate viewing applications.

- Built-in collaboration and versioning: Conversations, feedback, and change history happen directly in the model environment, supporting better traceability and faster iteration.

As MBD support matures within cloud-native environments, engineering teams will gain a far more agile, connected, and efficient way to define and deliver products — positioning themselves to fully realize the promise of model-based practices.

Final Thoughts

Model-Based Definition represents a shift toward richer, more reliable communication across the product development lifecycle. By embedding key information directly into your 3D models, your team can streamline processes, reduce errors, and improve product quality.

And with the help of cloud-native tools like Onshape, the barriers to adoption are lower than ever.

If you're starting your journey toward MBD or exploring ways to modernize your digital workflows, now is the time to take a closer look.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more