Cloud-Native PDM Software With CAD

Transform how CAD data is managed, accessed, and stored with Onshape’s built-in PDM.

Transform how CAD data is managed, accessed, and stored with Onshape’s built-in PDM.

What is Product Data Management (PDM) software?

Product Data Management (PDM) software centralizes CAD information so engineers can efficiently store, search, and manage their design data.

Onshape's PDM is built into its cloud-native CAD platform, serving as a foundation for all its CAD workflows. This modern approach simplifies data management and makes design data accessible to those who need it.

Key Features

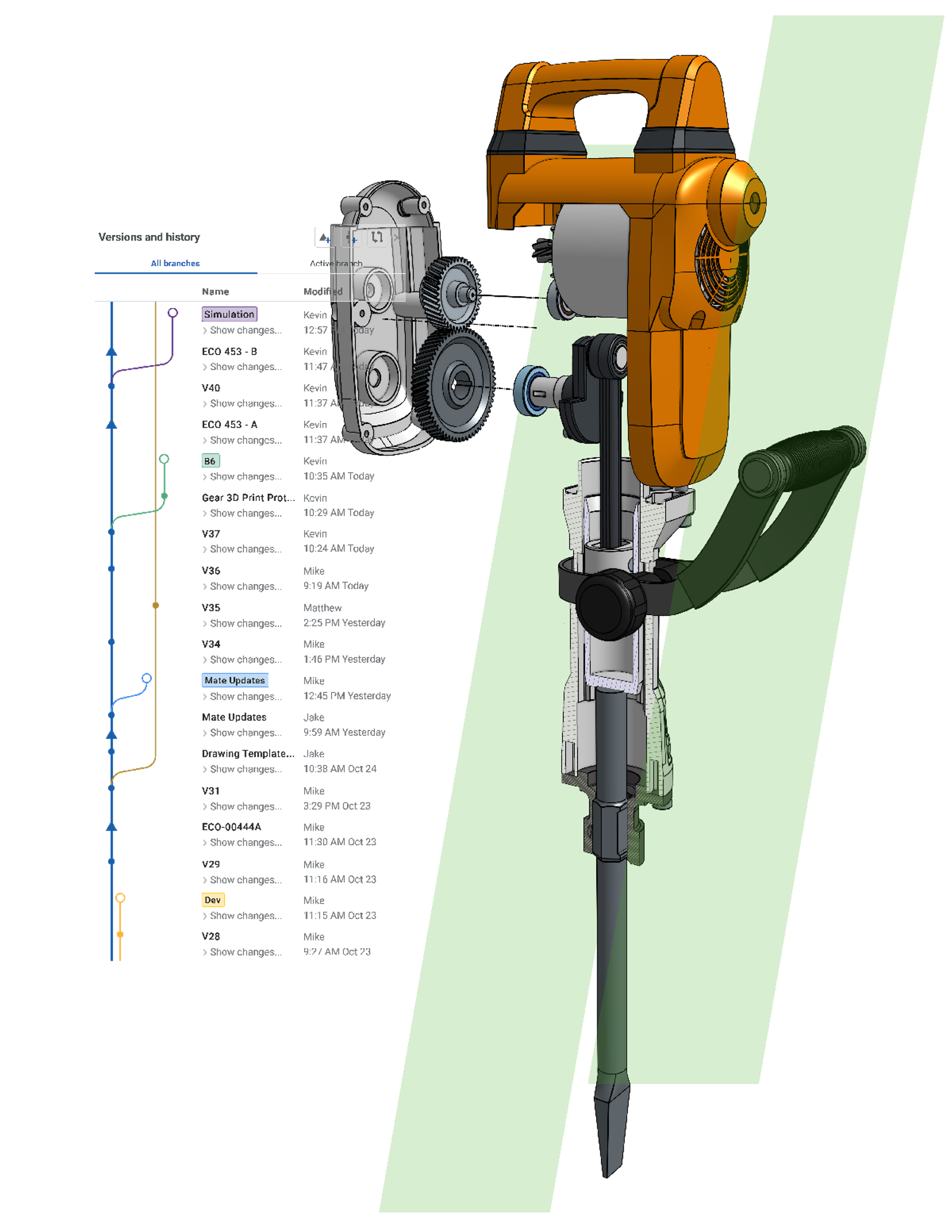

History, Versions, Compare

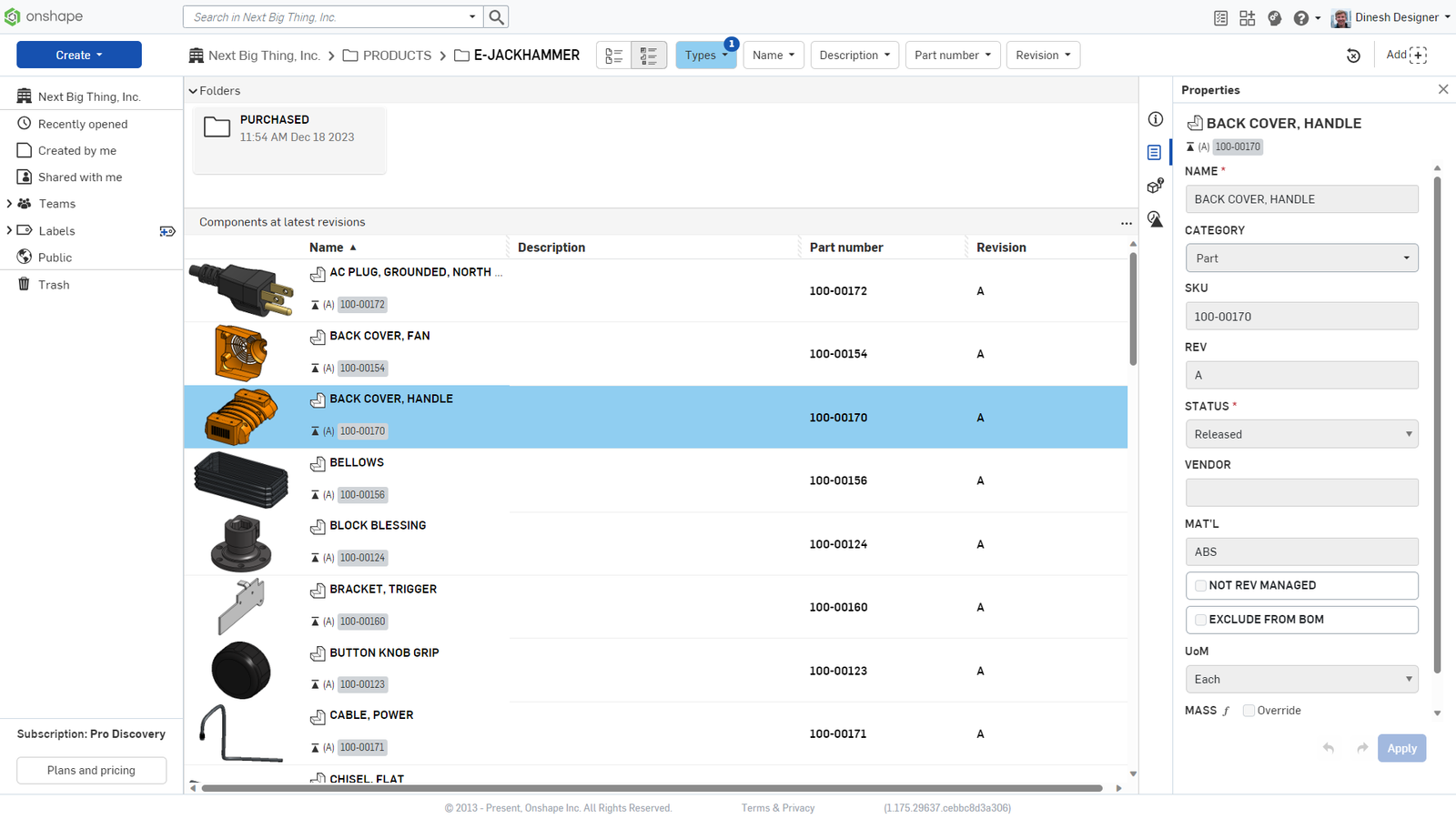

Onshape's built-in PDM stores all CAD data in Documents. These can contain assemblies, drawings, BOMs, media like images, videos, or PDFs. Onshape Documents centralize data and keeps a tracking of the entire access and edit history so users can easily revert back to an any previous state of the design.

Users can also compare designs to previous versioning.

Branching and Merging

Onshape helps teams iterate, discuss, and find solutions quickly through branching and merging which enables multiple engineers to work on the same design concurrently, without conflict.

Branching creates independent workspaces for individuals to explore ideas without fear of disrupting others' work. Teams can easily manage design conflicts with tools to compare and merge selective changes into the main design.

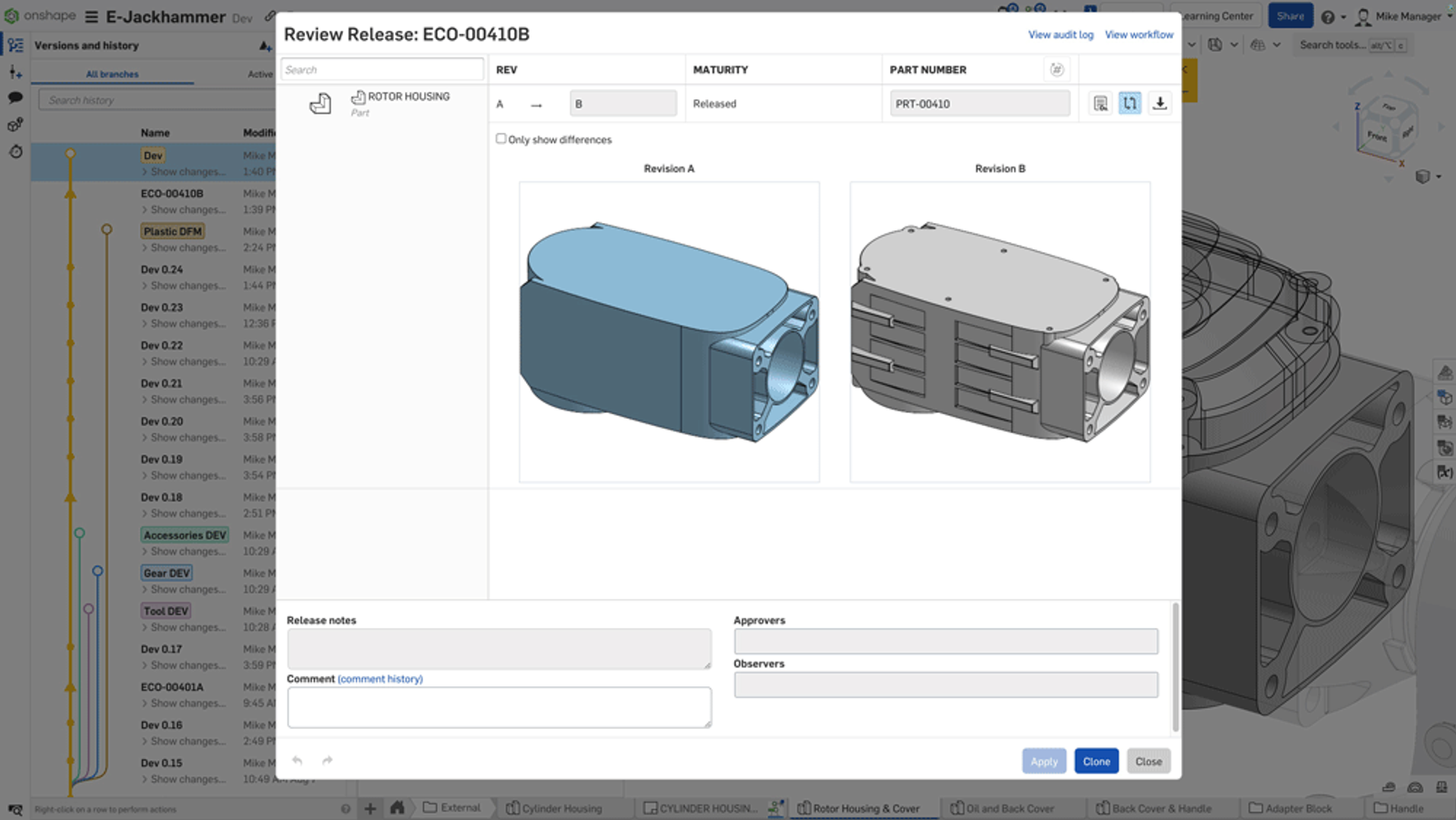

Release Management

Onshape accelerates release processes from hours or days to mere minutes by automatically organizing design data and eliminating the need to locate CAD files.

Set up release processes in just a few steps, including review and approval workflows, roles, and company preferences.

Additionally, Onshape makes it easy to share the correct, approved design with your extended manufacturing team and eliminate the need for CAD version-specific viewing tools through Publications.

Advanced Search

Onshape’s Where Used is a powerful tool for tracking where a part has been used in an assembly. It can also help you locate instances where custom features have been applied.

Can’t remember a name or part number? Simply search by property values to find any Part, Assembly, Drawing, or Document.

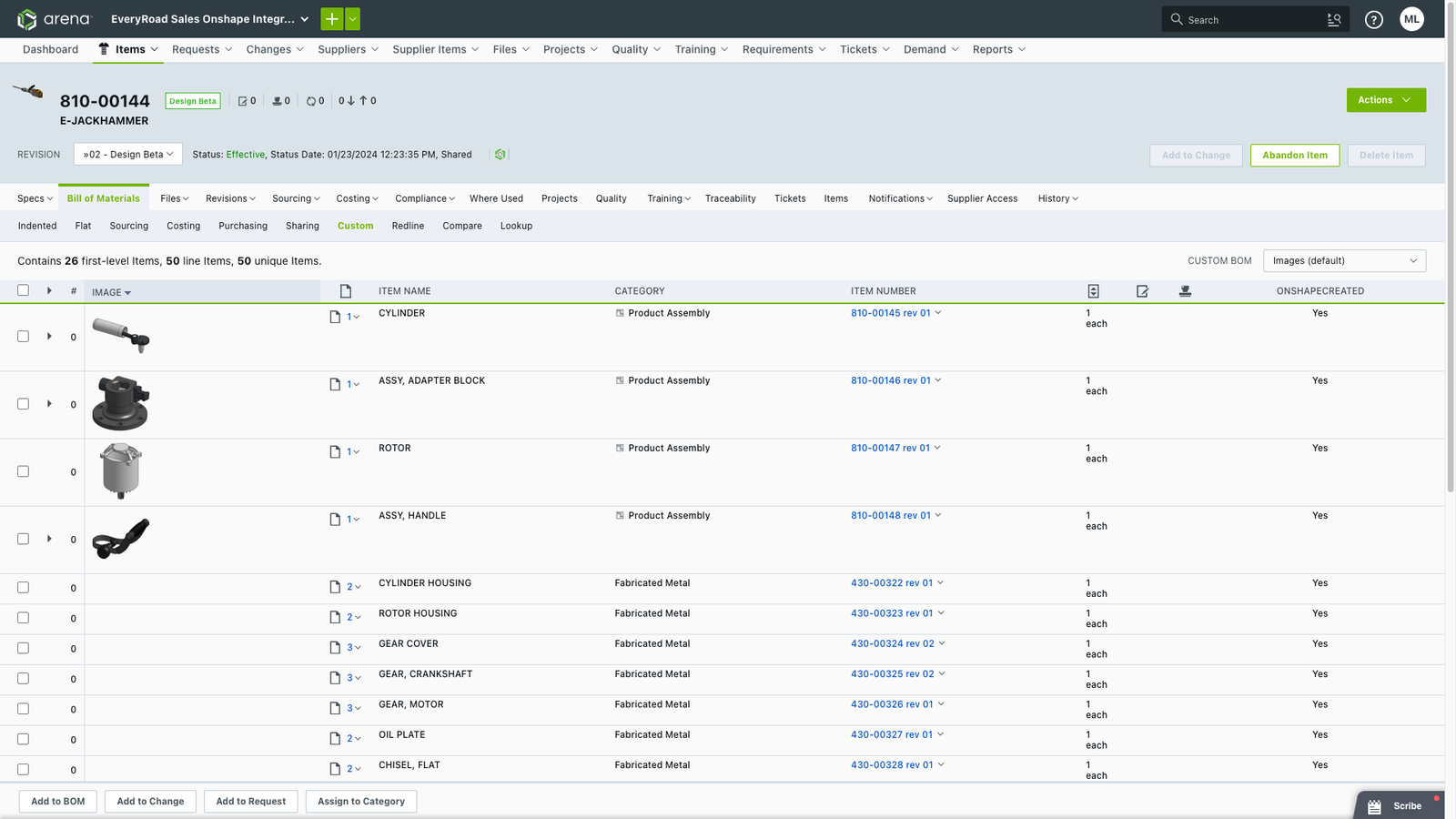

PLM

Extend your data management benefits with the Onshape-Arena Connection, which integrates CAD, PDM, and PLM in the cloud.

The Connection enables real-time sharing of design information between engineering and operations teams while eliminating the complexities, administrative burdens, and excessive costs associated with traditional PLM integrations.

Explore More

Learn how Onshape’s Cloud-Native CAD and PDM provide a complete, searchable, and secure product development platform with built-in version control and release management tools.

5 Ways Built-In PDM Makes Engineering Data Management More Efficient

12.11.2024

Discover how CAD with built-in PDM transforms engineering data management through real-time collaboration, streamlined workflows, and cloud-native capabilities.

Read Blog

Boost Your Design Productivity with Cloud-Native PDM

09.03.2024

With PTC’s Onshape, PDM isn’t just an add-on, it’s built into the system. Learn how CAD with a built-in PDM system can unlock your design’s potential.

Read Blog

Debt by a Thousand Files: Unveiling the Hidden Costs of File-Based CAD Systems

01.02.2025

Explore how file-based CAD systems contribute to design debt – product development’s technical debt – and its impact on business outcomes. Then, learn how to improve efficiency through cloud-based solutions and modern data management practices.

Read Blog

Maximizing Team Productivity & Efficiency with Built-In, Cloud-Native PDM

09.13.2024

What if your team had a PDM system that worked seamlessly in the background – boosting productivity, improving collaboration, and speeding up product development?

Read Blog

Never Lose a Design Decision: Onshape's Version Control Time Machine

04.16.2025

Onshape's built-in version control works automatically from your first sketch. Learn how automatic versioning transforms your CAD workflow.

Read Blog

4 Things That Successful CAD Managers Can’t Afford to Ignore

01.04.2024

How well is your CAD system meeting your day-to-day hardware design challenges? Here are 4 things that successful CAD managers can’t afford to ignore…

Read Blog

4 Ways to Lose CAD Files and How to Prevent It

06.07.2024

There's nothing worse than losing your CAD files, and with traditional CAD there are lots of reasons it happens. Learn how cloud-native CAD can prevent disaster.

Read Blog

Eliminating CAD Version Control Issues with Onshape’s Single Source of Truth

04.17.2024

What are the best ways for engineering teams to manage CAD version control issues?

Read Blog

Get Started with Built-in PDM in Onshape

Have Questions?

For more answers or to ask a question, head over to the Onshape Forum.

What does it mean that Onshape’s PDM is built in?

How is Onshape’s cloud database approach better than file-based data management?

What is an Onshape Document?

Is there a data storage limit?

How can I share CAD data or an Onshape Document?

Can I customize Onshape’s data management?

What Analytics are available?

Is Onshape’s PDM fully cloud-based, or does it require any downloads or local servers?

How is Onshape’s PDM different from file-based and on-premise systems like SOLIDWORKS PDM, or Autodesk Vault?

Can Onshape’s PDM manage data from other CAD tools?

How does version and release management work in Onshape’s PDM system?

How does Onshape’s PDM integrate with PLM, ERP, or MES, CAM, and CAE systems?

How much does PDM software cost, and what pricing models does Onshape offer?

Whenever I describe Onshape to anybody, I always say, ‘It's like the Google Docs of CAD,’ and they're instantly like, ‘Oh, that makes so much sense. Why haven't they (the CAD industry) done that already?’ ’’