The Challenge

Cirkul is an all-natural, zero-calorie beverage company that makes proprietary flavored water bottle cartridges allowing users to control their own flavor intensity. In 2022, Cirkul water bottles were one of the Walmart home division’s fastest-selling products. Back in 2018, Cirkul was seeking a better way to manage version control of its designs between multiple locations, and also wanted a CAD system that didn’t require its engineers to manage servers and software installs/upgrades. Cirkul says 50 percent of one engineer’s design time was previously devoted to IT administrative tasks.

Results

- Cirkul saves an estimated $50,000+ a year in engineering time due to no longer having to manage servers, CAD licenses and other IT administrative tasks.

- Onshape’s built-in PDM provides automatic version control for product designs, reducing the risk of manufacturing errors.

- Real-time CAD collaboration tools streamline communication between Cirkul’s engineering team in Massachusetts and its manufacturing team in Florida.

- Cirkul plans to expand its engineering team from 20 to 35 engineers over the next year. Onshape’s cloud-native CAD and PDM platform enables immediate onboarding of new employees in a web browser, versus waiting for software procurement and installs.

Instead of sending CAD files around, you just share a link. That’s something we’ve really leaned into as we’ve grown as a team… Onshape makes it really easy to share up-to-date information across different locations. ’’

Water, of course, has been consumed by humans since the dawn of civilization. But never have there been so many choices of flavors – or so many options for how to drink it.

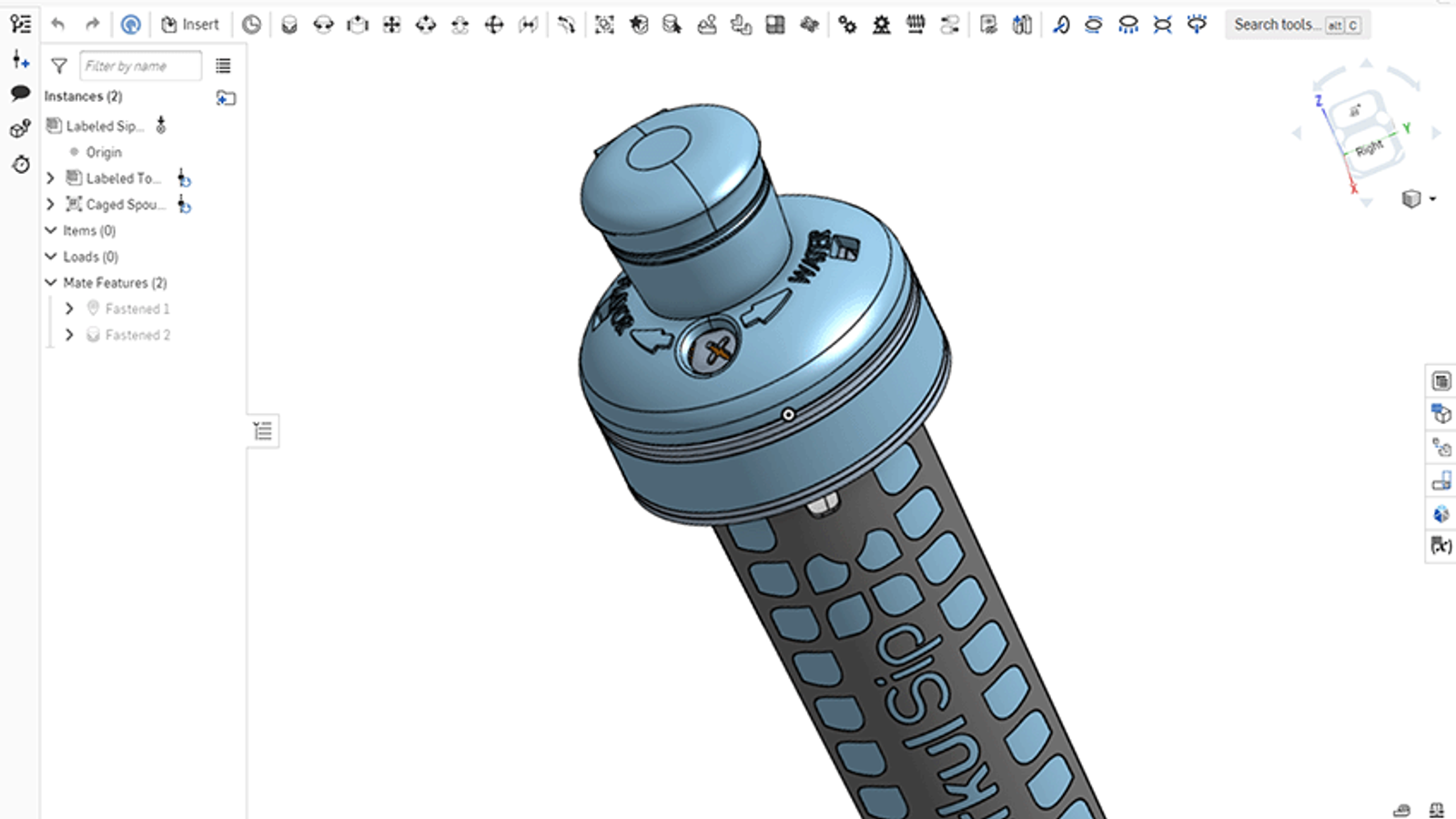

Aiming to “make drinking water convenient, delicious, and fun,” beverage technology company Cirkul has reinvented how water gets flavored, replacing messy powdered mixes with patented filter cartridges (called “Sips”) that allow users to customize their flavor intensity.

Cirkul users can switch between plain water and a plethora of zero-calorie, all-natural flavors (including coffees, teas and energy drinks) with a flavor dial built into the water bottle lid. On a medium setting, each Sip cartridge can flavor about six water bottles, resulting in 84 percent less plastic use compared to consuming traditional bottled beverages.

Because users provide their own water, shipping only empty bottles and flavor cartridges also significantly reduces the weight and volume. The company says this reduces carbon emissions by 99 percent compared to trucking their competitors’ products.

Cirkul founders Andy Gay and Garrett Waggoner hatched the idea for flavor cartridges a decade ago when they were Dartmouth College football teammates, frustrated by the spillage of sports drink powders while pouring them into narrow bottle openings. They later won their school’s entrepreneurship pitch competition.

The Cirkul beverage platform is now sold at Walmart and Bed Bath & Beyond stores across the United States, and has become a viral sensation on social media – with TikTok videos alone attracting millions of views. In 2022, Cirkul water bottles were one of the Walmart home division’s fastest-selling products.

Ironically, the Cirkul product design team is currently based on Water Street in Watertown, Massachusetts (suburban Boston).

Onshape Eliminates IT Overhead for CAD Software

The Cirkul engineering team relies on Onshape – a cloud-native CAD and PDM platform with built-in collaboration and simulation tools – to design its products and manufacturing fixtures.

Cirkul switched to Onshape from their file-based CAD system in 2018, after experiencing significant bottlenecks related to software and server maintenance, managing licenses and upgrades, and other IT administrative tasks.

According to Tom Urbanik, VP of Engineering, software maintenance and installs were eating up 50 percent of one mechanical engineer’s time – a tough-to-swallow efficiency loss for a small company.

“The engineering bandwidth it took to support our old CAD system was so painful,” he recalls. “We experienced significant downtime managing servers just to keep them up and running. There’s no compelling reason to suck up engineering time to support something that’s not your core business.”

“When we first started out and were a much smaller startup, we only had one floating license between the two of us,” adds lead mechanical engineer Cole Houston. “If we were in the same office, there was no problem, but if one of us were traveling, that meant that only one of us had the license. The other person might not be able to work on a design for a week or so.”

Onshape requires no restrictive licenses and has zero IT overhead. Server maintenance and automatic software upgrades every three weeks are included in the cost of an annual subscription. CAD access is available anytime on any computer or mobile device (iOS or Android).

Urbanik says that Onshape saves his team a minimum of $50,000 a year in reclaimed engineering hours.

“Onshape gets rid of all the silly maintenance things,” he says. “All we have to do is focus on our own workflows. It’s hard to find good people. So I never want to waste their time on software implementation.”

Cloud-Native PDM Delivers a Single Source of Design Truth

Another motivating factor for switching to cloud-native Onshape was its built-in PDM system, Urbanik says.

“File management was really important to us,” he notes. “I can’t tell you how many times people would privately have CAD files squirreled away on their computer. It’s dangerous when you have no idea what the point of truth is when everyone actually has a different file. Because everyone’s made their own personal changes to the design and it hasn’t synched back.”

Onshape’s built-in version control and release management eliminates the need to purchase expensive add-on PDM software. Having everyone on the team working from the same single source of truth significantly reduces the risk of manufacturing errors.

“When we have an injection-molded part, it can cost hundreds of thousands of dollars and take months to manufacture,” Urbanik says. “I can’t even fathom what a mistake looks like if we accidentally send the wrong version of the design and have vendors quoting us based on the wrong information.”

With Onshape’s built-in PDM, whenever a team member anywhere makes a design change, everyone else on the team can instantly see it. A comprehensive Edit History also tracks who made which change and when, allowing the team to quickly revert back to any earlier design iteration if desired.

Cirkul also relies on Onshape’s version control and real-time CAD collaboration tools to streamline communication between its engineering team in Massachusetts and its quality control team in Florida. About 80 percent of Cirkul manufacturing and 100 percent of product assembly is done in the United States.

“Instead of sending CAD files around, you just share a link. That’s something we’ve really leaned into as we’ve grown as a team,” says Houston. “We’ve also migrated all our documents to a cloud-based storage platform. Everyone always has access to the same exact thing. Onshape makes it really easy to share up-to-date information across different locations.”

Scaling Up: Onshape Accelerates Engineer Onboarding

According to Urbanik, Cirkul expects to expand its engineering team from 20 to 35 CAD users over the next year. He says that Onshape is especially helpful in speedily onboarding new engineering hires because procuring CAD access is instant, versus having to wait days (or longer) to purchase traditional software licenses.

One of the biggest manufacturing challenges for Cirkul to date has been part interchangeability. The company sources out 2 or 3 different suppliers for each component of their Sip flavor cartridges, aiming to generate a robust supply chain and better control costs. To keep track of all the moving pieces, Cirkul uses the cloud-native Arena Product Lifecycle Management (PLM) platform, also owned by Onshape’s parent company, PTC.

Urbanik says he is looking forward to using the new Onshape-Arena PLM Connection tool, which enables engineers, manufacturers and suppliers to instantaneously share the latest product design and business information at the click of a button.

“The PTC-Onshape-Arena umbrella feels like the future for us,” he says. “I feel really committed to the whole platform.”