The Challenge

Exxentric is a leading provider of flywheel strength training equipment. Leveraging flywheel technology, its wide array of products provide vast benefits over traditional weight training. Users range from professional sports teams, rehabilitation facilities, and health & fitness groups. Founded in Sweden in 2011, Exxentric has grown consistently over the ensuing years. Today its product range, consisting of a number of flywheel devices on which multiple strength exercises can be performed, is shipped to over 75 countries worldwide. In December 2017, the company decided to switch from SOLIDWORKS, its old file-based CAD system, to PTC Onshape’s cloud-native CAD and PDM platform. This would not only enable them to design higher quality products more efficiently and for less cost, but enable stakeholders across the business to better collaborate on designs.

Results

- Exxentric has been able to significantly optimize designs through Onshape’s built-in simulation.

- Onshape’s automatic version control provides a single source of truth, enabling the design team to keep track of updates.

- Onshape improves collaboration across departments and with suppliers through the ability to easily share CAD files via a URL.

- Real-time CAD collaboration tools streamline communication with the manufacturing team.

One of our key differentiators from other flywheel training companies is that we have a laser focus on quality. Our goal is to design products that are as high quality and efficient as possible, and Onshape certainly helps us in reaching that goal.’’

You may have possibly wondered how astronauts who spend most of their time weightless and sedentary on space flights ensure their muscles don’t waste away.

In the early 1990s NASA was pondering the same thing. The solution to strength training came in the form of a flywheel training device.

“Flywheel training offers optimal resistance for the user. This resistance is created through the inertia of a flywheel as a result of its rotation and not due to gravity. For that reason flywheel training works in outer space, it is very future proof,” says Andreas Ahlström, product design engineer at Exxentric.

Back down on Earth, flywheel training is also proving its effectiveness over traditional strength training systems, and Exxentric is a leader in this market. Since its foundation in 2011, when its two co-founders created a prototype for a flywheel multi-exercise device to more effectively train young ice hockey players, this Sweden-based company has continually launched new products and experienced consistent growth. Today, its products are shipped to over 75 countries across the world.

From elite athletes such as the Buffalo Sabres ice hockey team to individuals working out at home, Exxentric’s equipment is suitable for all types of resistance training, from heavy strength training to rehabilitation.

What is flywheel training?

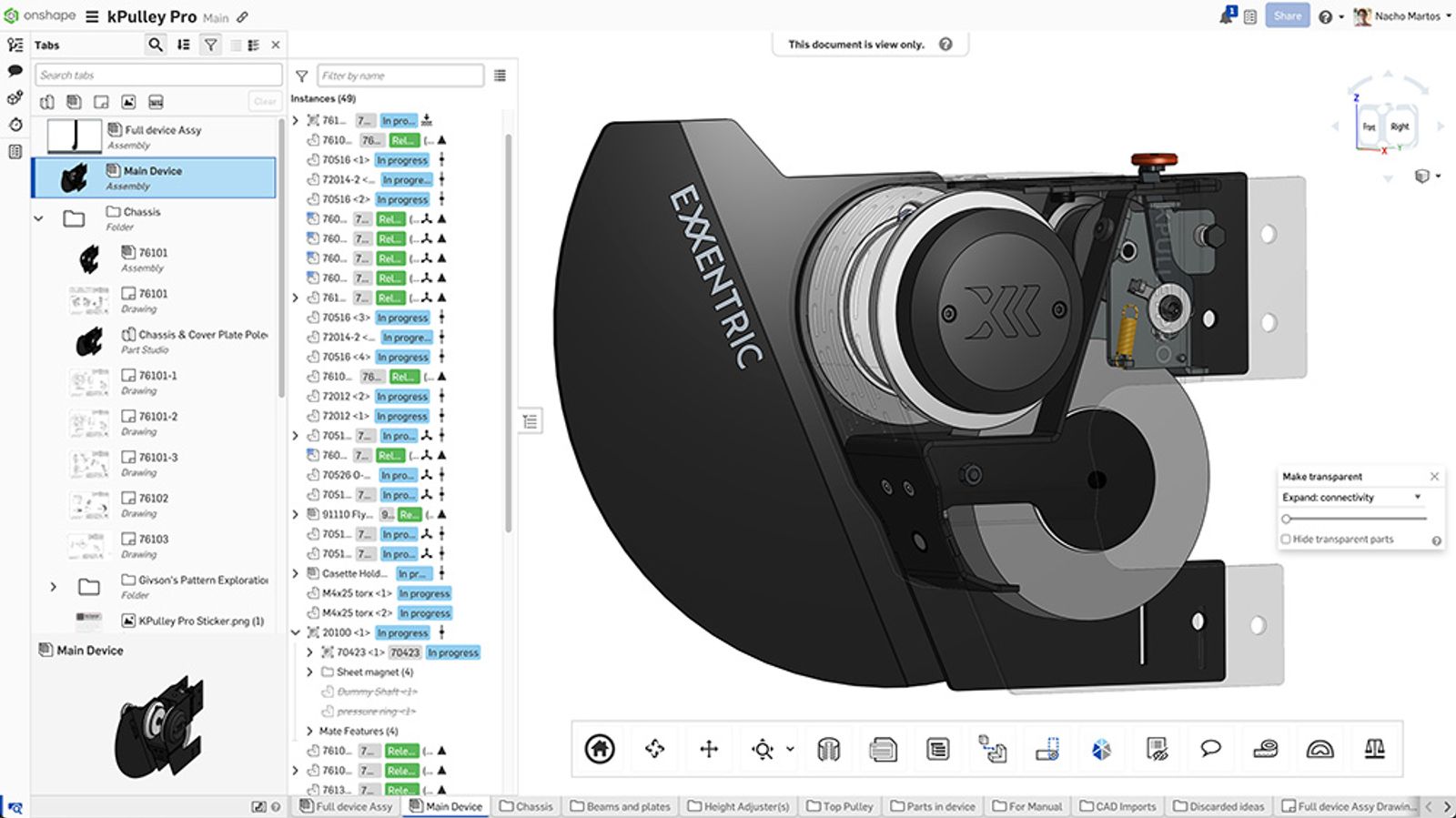

As opposed to conventional weight training in which the user lifts a weight such as a barbell against gravity to create resistance, flywheel training is based on the inertia generated by a spinning flywheel, which is accelerated or decelerated with muscle force. The level of inertia of the flywheel rather than the weight determines the force needed.

“When I describe flywheel training to my friends I tell them to think of a yoyo device as it is the same principle,” says Albin Arvidsson, CAD designer at Exxentric.

“A flywheel training device consists of a shaft with a band on it. As you pull in the band and it unwinds from the shaft, the wheel starts to spin. Once all the band is unwound from the shaft, it will then wind up again. Just like a yoyo. So, the harder you pull the band – the harder it pulls back,” he describes.

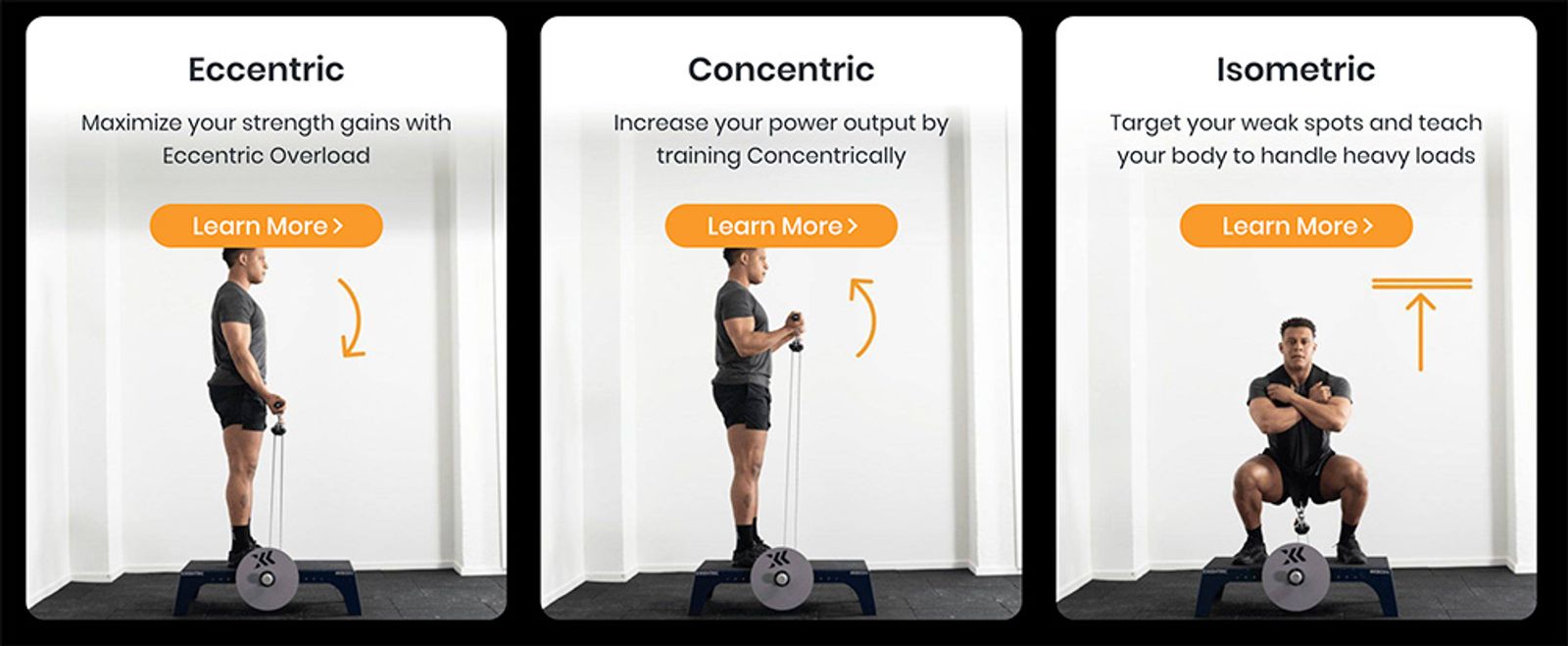

A key advantage of Exxentric’s flywheel training products is the ability to train the user’s muscles effectively in the eccentric phase (when the muscles lengthen), which is limited when training with traditional weights. Our muscles are stronger in the eccentric phase as compared to the concentric phase (when the muscles shorten), and with Exxentric’s products the eccentric phase can be loaded to its maximum. Users are also able to achieve all their strength training goals and perform multiple exercises using a single, portable device.

Optimizing designs with Onshape leads to higher quality products

To design its various flywheel devices, Exxentric relies on PTC’s Onshape - a cloud-native CAD and PDM platform with built-in collaboration and simulation tools.

“One of our key differentiators from other flywheel training companies is that we have a laser focus on quality. Our goal is to design products that are as high quality and efficient as possible, and Onshape certainly helps us in reaching that goal,” says Ahlström.

When Ahlström joined Exxentric, the company had recently switched to Onshape from SOLIDWORKS. “Our CEO, who is very forward thinking and likes innovation, felt that file-based CAD systems were outdated and clunky. He was drawn to Onshape’s collaboration capabilities enabled by it being cloud-based,” he says.

Arvidsson adds, “We currently have six licenses of Onshape for our small, agile design team. All members of the design team collaborate in the design of our products and being a small company we are all heavily involved in every aspect of the design process from the investigation phase and concept sketches all the way through to the assembly of the first production models.”

Following 2D sketching and idea generation, the chosen design concept very quickly enters the development phase where Onshape is used to create a detailed 3D model.

“We’ve recently started using Onshape’s stress simulation tools to really optimize our products. A few years back we would have perhaps created bigger products than we needed to as we didn’t have the tools to evaluate the mechanical properties of the design and perform structural analysis. However, we are now able to design better quality products faster and for less cost,” says Ahlström.

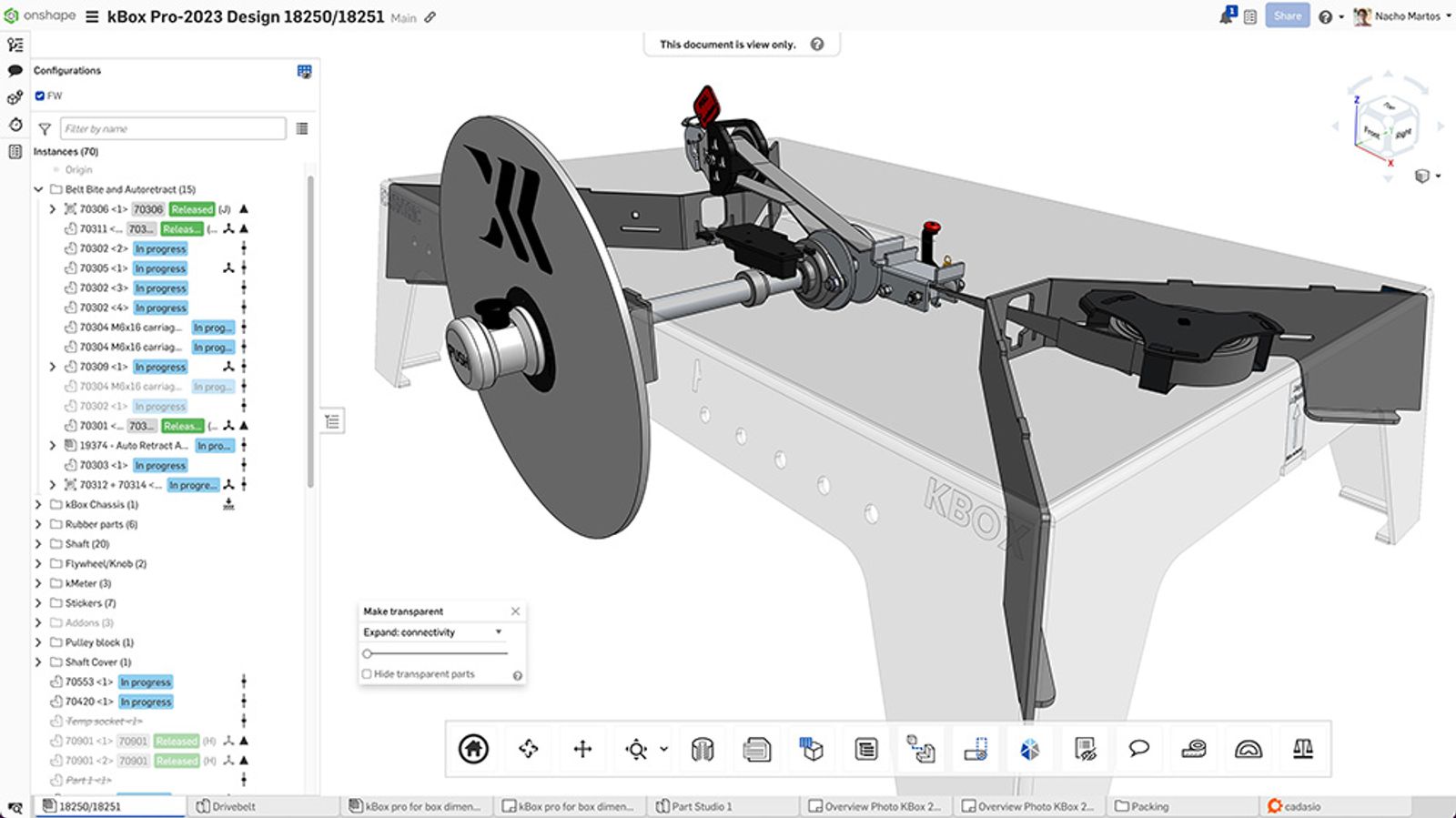

Automatic version control brings vast benefits to the design process

Working collaboratively on every project, the design team have found Onshape’s automatic version control to be one of the most beneficial features of the tool. Any time a team member makes a design change, everyone on the team can instantly see it. A comprehensive edit history also tracks who made which change and when, allowing the ability to quickly revert back to an earlier design iteration if desired.

As Arvidsson says, “From the first sketch, everything to do with the product is in one place. You don't need to save the file on a computer and then reopen the assembly and replace an old file with a new one. Instead you have many folders in the same document and you can just choose which version you would like to see. If you make any changes in the assembly these are updated in real-time. It’s a really great feature.”

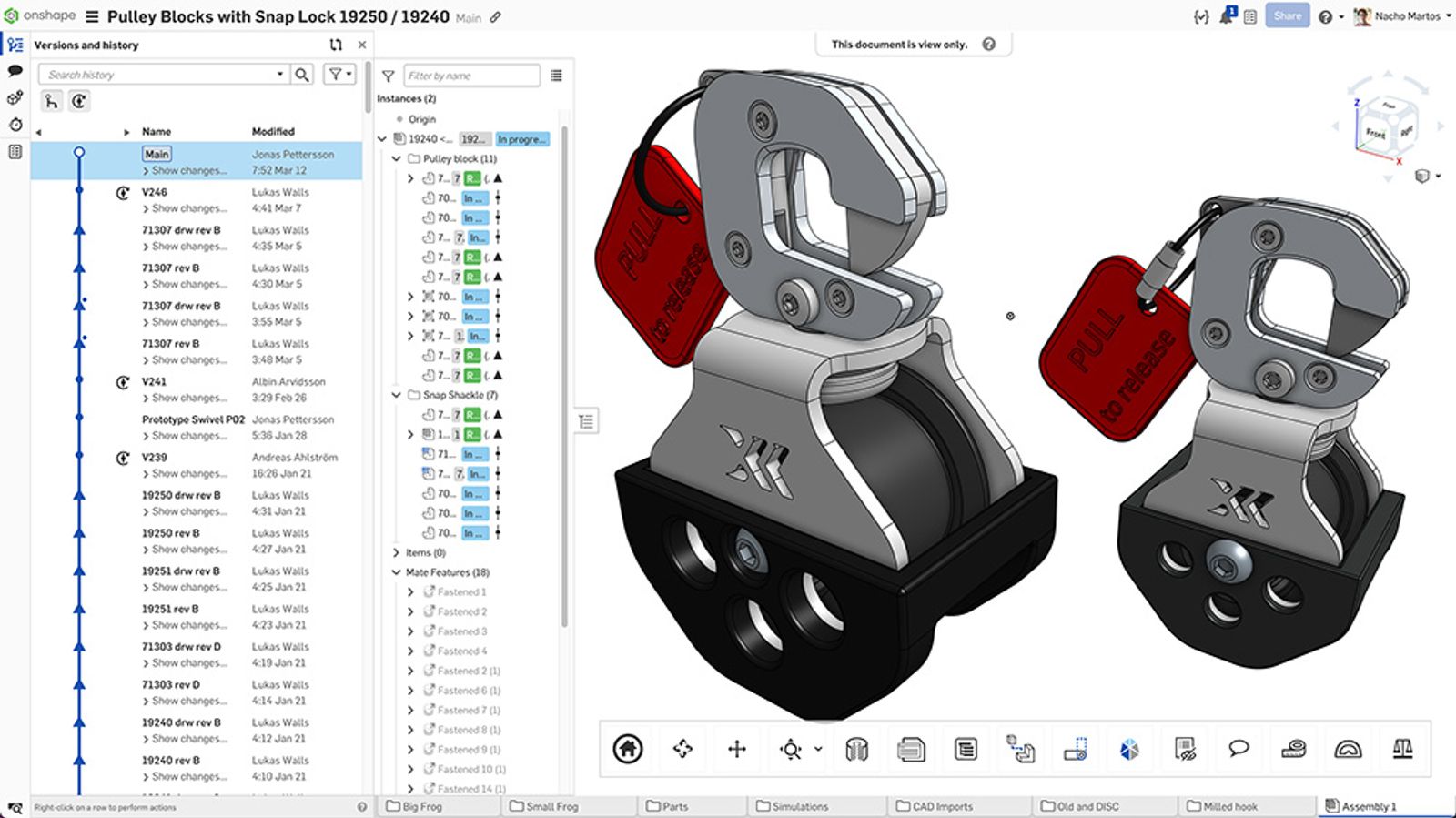

Ease of collaboration between designs and stakeholders

Onshape also enables CAD collaboration across departments and with suppliers, even if they are non-CAD users. This is vital during the development phase when expertise and feedback can be critical to the design.

For instance, most of the product’s main parts are made from sheet metal and the ability to share files with the sheet metal supplier earlier in the design process has proven very useful.

“We use Onshape’s sheet metal tool to create the parts. We feel sheet metal has certainly improved since we’ve been using it through various software updates. We can then easily send a link of the CAD file to our supplier who can then quickly provide input into whether there are any issues in the design that could be encountered during manufacturing,” says Ahlström.

Arvidsson adds, “Other people can also log into our CAD system without having it on their computer or without having any knowledge of how to use it. If our CEO, for instance, would like to see the parts or the assembly, he can go into Onshape and check it out. The same for our purchasing department, they can download files from Onshape and send it to the supplier without us having to do that for them.”

Onshape is helping Exxentric be better

Having used Onshape for a few years now, Ahlström and Arvidsson have noticed certain features are updated and added every three weeks. Being cloud-based, server maintenance and automatic software upgrades are included in the cost of an annual subscription.

“Not only can we easily access help from Onshape’s support if we have an issue or a problem but we can also report a missing feature that we feel could help us. Sometimes we’ll log in after an upgrade and the feature we requested will be there. This really makes us feel as though the Onshape team is listening and wants to help us be better,” says Arvidsson.