1:24

As your CAD geometry evolves, your CAM strategies need to stay aligned. Onshape’s CAM Studio provides efficient tools for regenerating toolpaths and managing changes, without the overhead of traditional file-based systems.

Learn how to keep your toolpaths accurate and your workflow streamlined.

Efficient Toolpath Regeneration

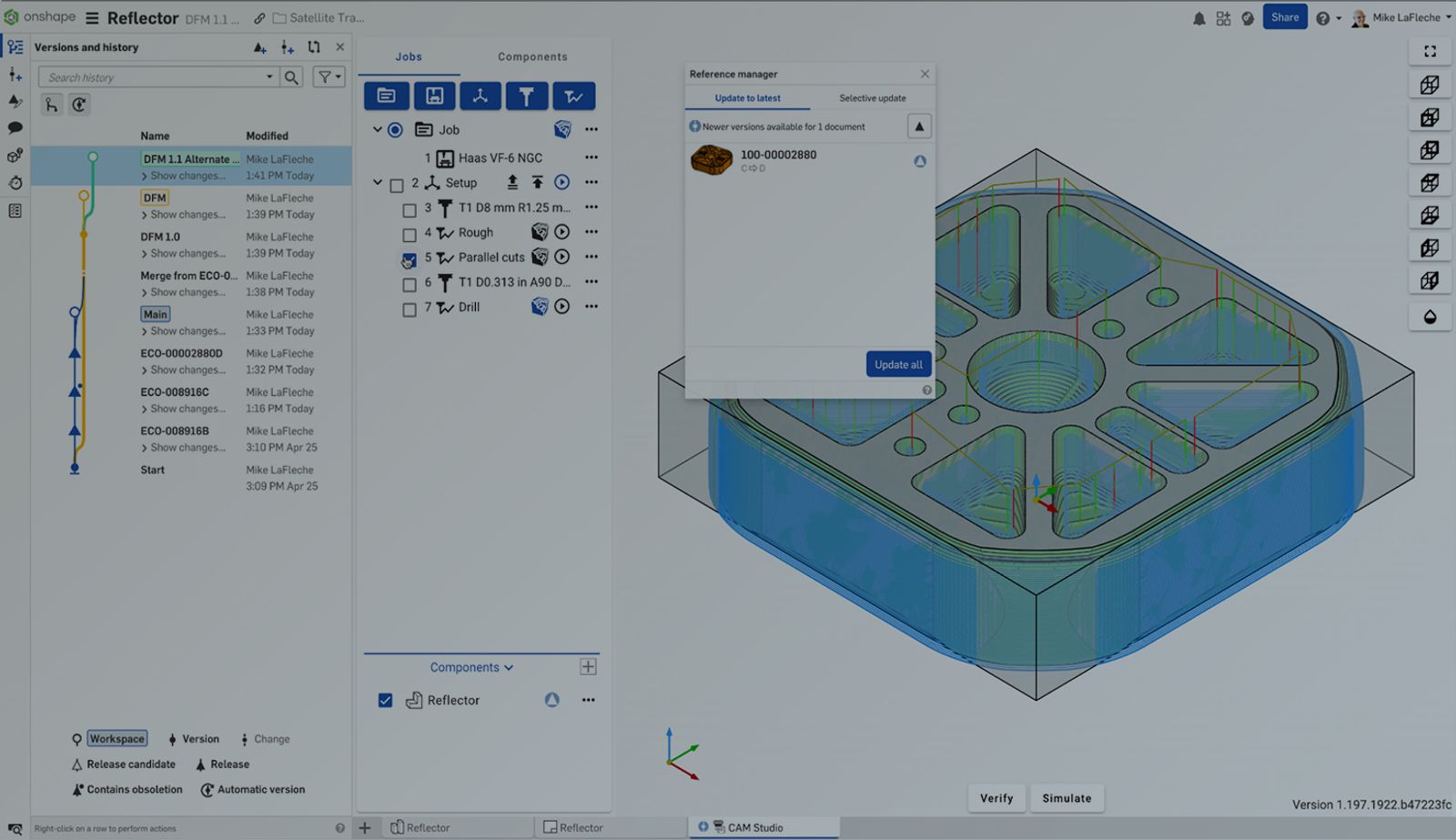

It is important to understand how Onshape CAM Studio minimizes unnecessary recalculations by caching toolpath operations. When your model changes, you can selectively regenerate affected toolpaths instead of reprocessing everything.

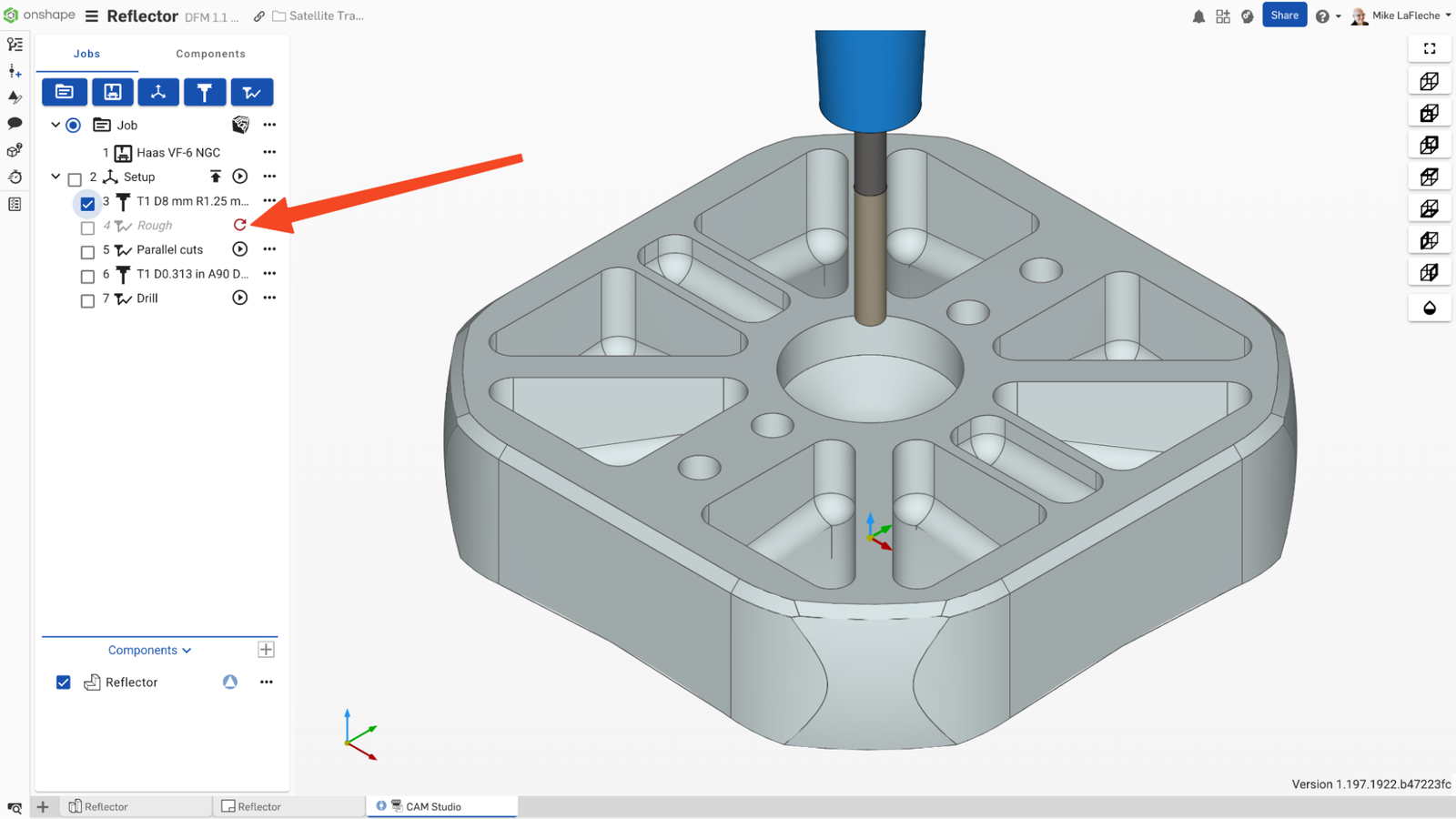

- To update a single operation, click the Regenerate operation button.

- To update an entire setup, use the right-click context menu and click Regenerate all toolpaths.

This focused approach saves time and ensures that your toolpaths stay in sync with the latest geometry.

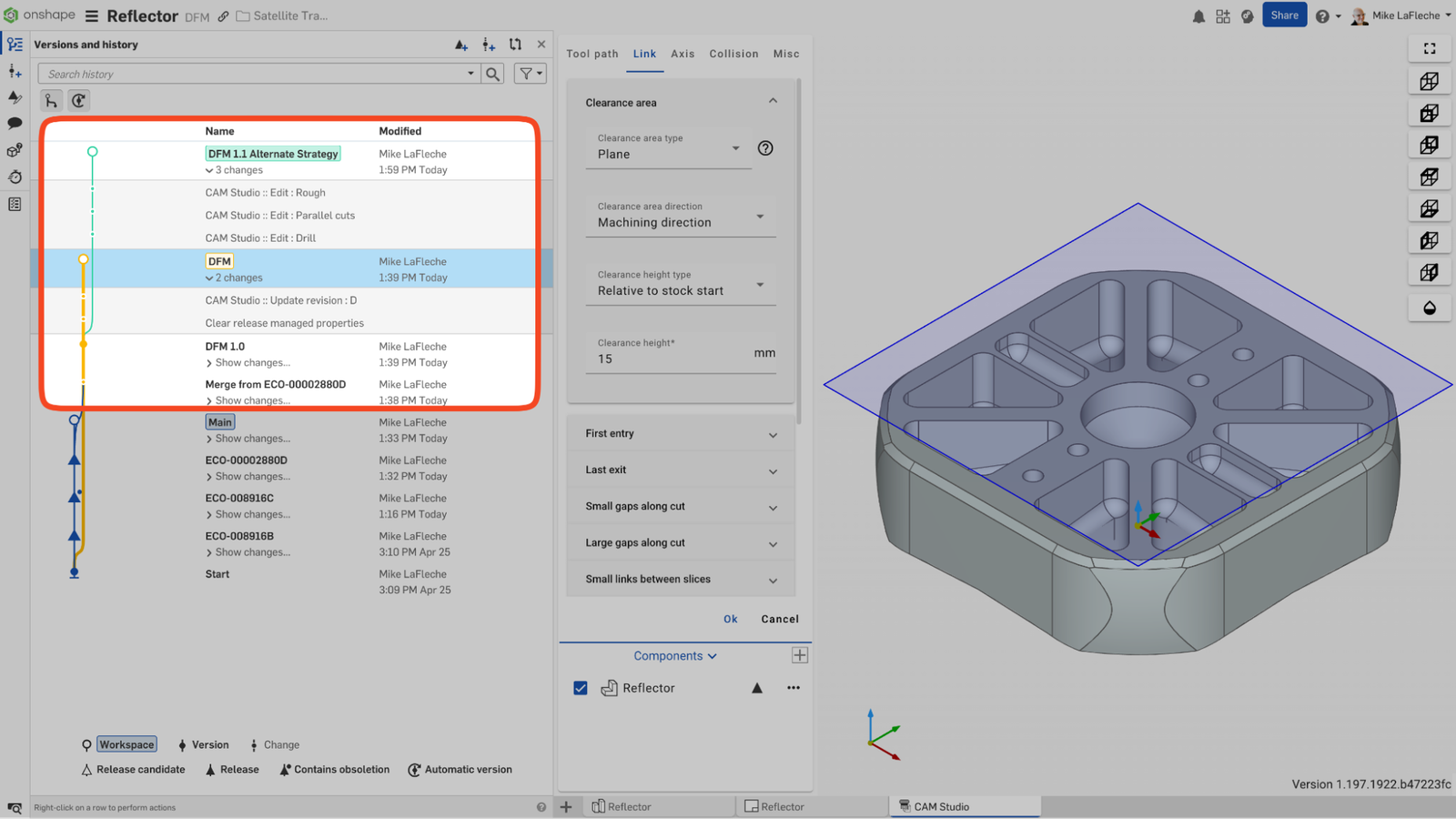

Versioning and Branching for Process Control

Next, Onshape’s integrated version control system offers a structured way to manage your CAM data.

Use versions to:

- Lock toolpaths to a specific geometry state for simulation of fixtures, design for manufacturing decisions, or prototyping.

- Create branches to explore alternate machining strategies without affecting the main workflow.

- Maintain a complete, traceable history of your design and manufacturing decisions.

With versions and branches, you can confidently manage design changes without the complexity of file copies, check-ins, or duplication.

Release Management for Production Stability

As you move from design iterations to production-ready output, Onshape’s Release Management provides the control and traceability needed for manufacturing.

- Reference only released revisions of parts and assemblies.

- Get notified when relevant components change, avoiding unnecessary updates; for example, when a part changes from Rev A to Rev B.

- Manage metadata and approval workflows across parts, assemblies, drawings, and even G-code.

This enables teams to work concurrently while maintaining control over production deliverables.

Transcript

Pro Tips for Using CAM Studio Effectively

- When updating complex setups, regenerate stock models from the last operation upward.

- Use versions to create checkpoints for design or toolpath validation.

- Use release management to ensure stable, documented references for production.

Fewer Errors with Onshape CAM Studio

By combining CAM Studio with Onshape’s versioning and release tools, you gain a reliable, integrated system for managing toolpath updates. The result is fewer errors, faster turnaround, and a more agile manufacturing process.

CAM Studio

Drive manufacturing quality and excellence with unified CAD/CAM in the cloud.

Latest Content

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more