4:31

Today marks a pivotal moment as we introduce CAM Studio Beta to the Onshape platform, with AWS. This release represents our most significant platform expansion to date, adding comprehensive manufacturing capabilities to PTC’s fully cloud-native product development solution.

Note: CAM Studio is currently in Beta. While core functionality is stable, we’re continuously enhancing features and performance based on user feedback.

CAM Studio: From Model to Machine

CAM Studio adds essential manufacturing capabilities directly within the Onshape environment. This new workspace provides the tools manufacturing engineers and machinists need to transform designs into machine-ready geometry.

Core Manufacturing Capabilities

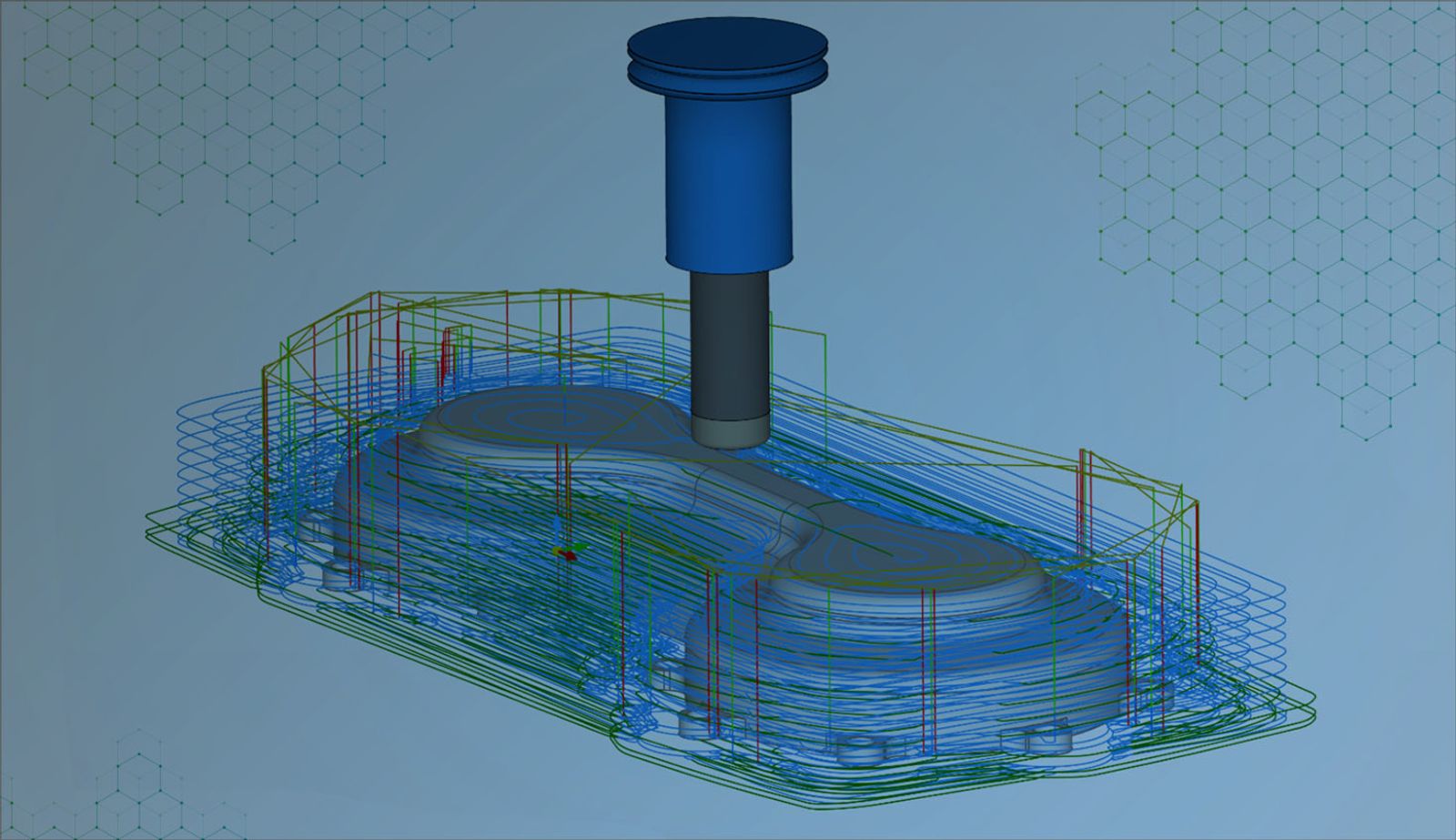

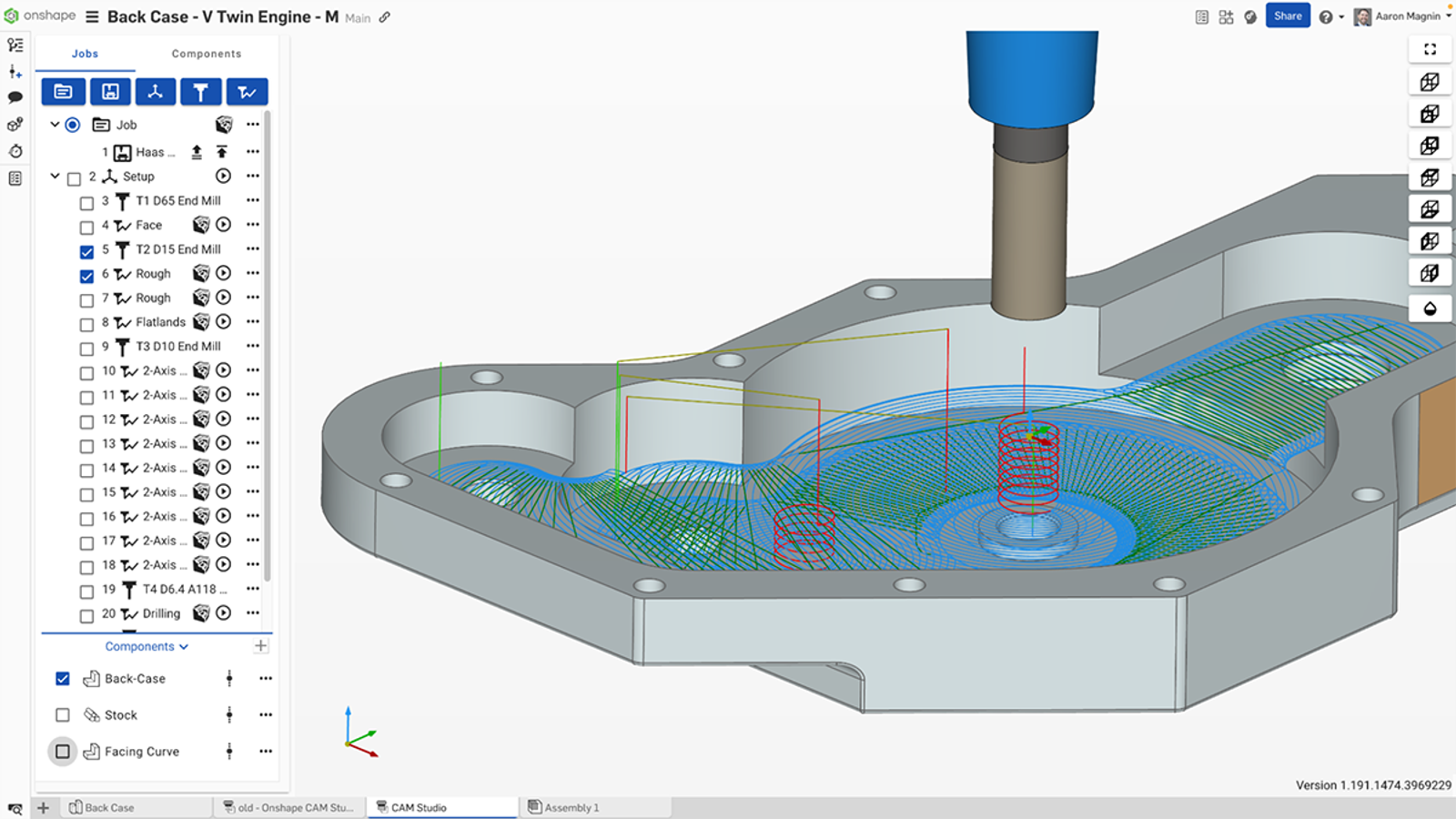

CAM Studio provides the tools you need to take your designs from model to machine. At its foundation, you’ll find support for 2.5-axis and basic 3-axis machining operations – the bread and butter of most CNC shops. Our toolpath generation engine handles everything from basic facing operations to complex adaptive clearing strategies, helping you optimize material removal rates while maintaining tool life.

We’ve built a comprehensive post-processor, machine, and tool library that supports the most common machines and machining operations right out of the box. And for those needing more customization, you can create your own custom tools.

CAM Studio also includes several powerful simulation options, including a fully integrated machine simulation environment. These tools help you verify everything before sending it to the shop floor.

Manufacturing Process Control

Getting the details right makes all the difference in manufacturing, which is why we’ve focused on giving you precise control over every aspect of the machining process. You can fine-tune cutting parameters based on your specific material and tooling requirements, and our stock definition system helps you visualize exactly how material will be removed with each operation.

Tool selection and path optimization work hand in hand – you can easily experiment with different tools and cutting strategies to find the most efficient approach for your parts. Once you’re satisfied with your setup, generating G-code is straightforward, and the system maintains a clear connection between your CAD model and manufacturing operations.

While CAM Studio operations are limited to one user at a time within a workspace, all team members maintain access to view manufacturing data and related documentation.

Power of the Cloud Advances Manufacturing Workflows

The integration of CAM Studio with Onshape’s cloud architecture brings unique advantages to manufacturing processes, fundamentally changing how teams approach design-to-manufacturing workflows. Let’s explore how our cloud-native approach transforms traditional manufacturing operations.

Ease-of-Access

One of the biggest advantages of our cloud-native approach is the simplicity of deployment. Since CAM Studio is fully integrated with Onshape, there’s no complex setup process to worry about. You won’t need to provision special hardware or manage software installations across your organization – if you can run Onshape, you can run CAM Studio.

Updates and maintenance happen automatically in the background, so you’ll always have access to the latest features without any IT overhead. All of this is delivered through your browser, making CAM Studio instantly accessible from any workstation that meets Onshape’s basic system requirements.

Up-to-Date Design Information

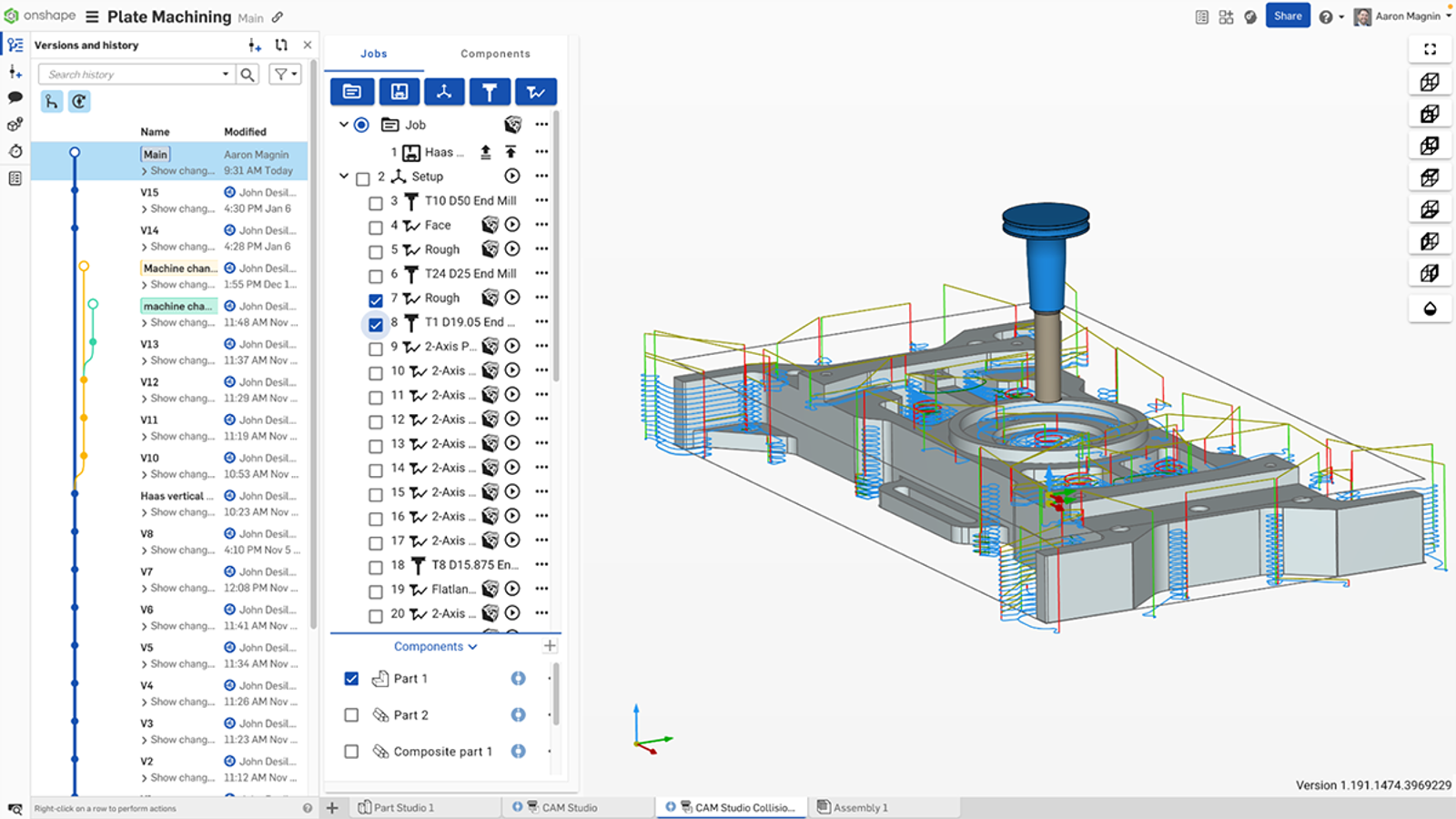

The real power of CAM Studio comes from its integration with Onshape’s cloud platform. When your design team updates a model, you’ll see those changes almost immediately – no more wondering if you're working with the current version. Our version control system tracks not just the design changes, but your manufacturing strategies as well, giving you a complete history of how parts evolve from concept to production.

Since everything runs in your browser, you can access your manufacturing data from anywhere with an internet connection. No more remote desktop sessions or carrying around a dedicated laptop.

Design-to-Manufacturing Collaboration

While CAM Studio limits editing to one user at a time to maintain process integrity, Onshape's platform enables powerful team collaboration. Manufacturing engineers can instantly see design updates as they happen, allowing for early feedback on manufacturability issues. Your entire team shares access to the same manufacturing documentation, ensuring everyone works from the same information.

For organizations with multiple facilities, you can standardize your process configurations across all locations, maintaining consistency in how parts are manufactured. The platform streamlines communication between design and manufacturing teams, replacing endless email chains with direct, contextual discussions. Best of all, your manufacturing knowledge stays centralized and accessible – from proven toolpath strategies to optimized cutting parameters – creating a valuable knowledge base for your entire organization.

Who Can Use CAM Studio?

CAM Studio is included with all commercial Professional and Enterprise subscriptions, making it immediately available to existing Onshape users. For teams interested in exploring our manufacturing capabilities, we offer access through our Discovery Program, which includes all the features of our Professional plan.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

CAM Studio Advanced

Available to try and later for purchase, CAM Studio Advanced takes your manufacturing operations to the next level. Advanced 3-axis machining allows you to machine the most detailed molds, while full 4-axis support opens up new possibilities for complex rotary work, and comprehensive 5-axis capabilities will let you tackle the most demanding geometric challenges.

Learn more about CAM Studio Advanced developments.

Dive Right into Onshape CAM Studio

Join our engineering team for an in-depth exploration of CAM Studio's capabilities and Onshape's cloud manufacturing advantages.

Our technical session will cover both CAM Studio's manufacturing capabilities and Onshape's cloud platform benefits through real-world applications.

This session is designed for manufacturing engineers, CNC programmers, and technical leaders who want to understand the integrated platform's manufacturing capabilities and cloud advantages.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more