03:26

The Bill of Materials (BOM) is the central nervous system of any manufactured product. It's the definitive recipe, the master list of every component, sub-assembly, and raw material required to turn an idea into reality. But in the world of product development, not all BOMs are created equal.

The disconnect between how a product is designed and how it is manufactured creates a fundamental challenge, a "semantic chasm" that is a primary source of enterprise inefficiency, costly errors, and production delays. The eBOM is the "as-designed" blueprint, a direct output of the engineering process that captures functional intent. The mBOM is the "as-manufactured" recipe, a translation of that design into a practical guide for production.

For decades, companies have been hindered by outdated, file-based CAD systems where this transformation is a manual, error-prone "hand-off". But modern, cloud-native platforms like Onshape are transforming this relationship, proving that a better eBOM is the essential foundation for a flawless mBOM.

Where the First Cracks Appear

The BOM is often an afterthought—a separate spreadsheet exported from the 3D model. This manual separation creates a cascade of problems:

- Version Control Nightmares: When a design change occurs, ensuring the separate BOM spreadsheet is updated is a major challenge. Multiple, conflicting versions of the BOM begin to circulate, leading to confusion and the procurement of incorrect parts.

- Manual Entry Errors: The process of manually transcribing data from a CAD model or PLM system into another document is notoriously prone to human error. A single typo can inflate costs and derail production schedules.

- Siloed Information: Integrating file-based CAD with PLM and ERP systems is complex and expensive. This disconnect means engineering is often working without visibility into manufacturing constraints, and manufacturing is working with outdated design data.

This broken process guarantees that the foundational step of the manufacturing workflow—starting with a complete and accurate eBOM—is built on shaky ground.

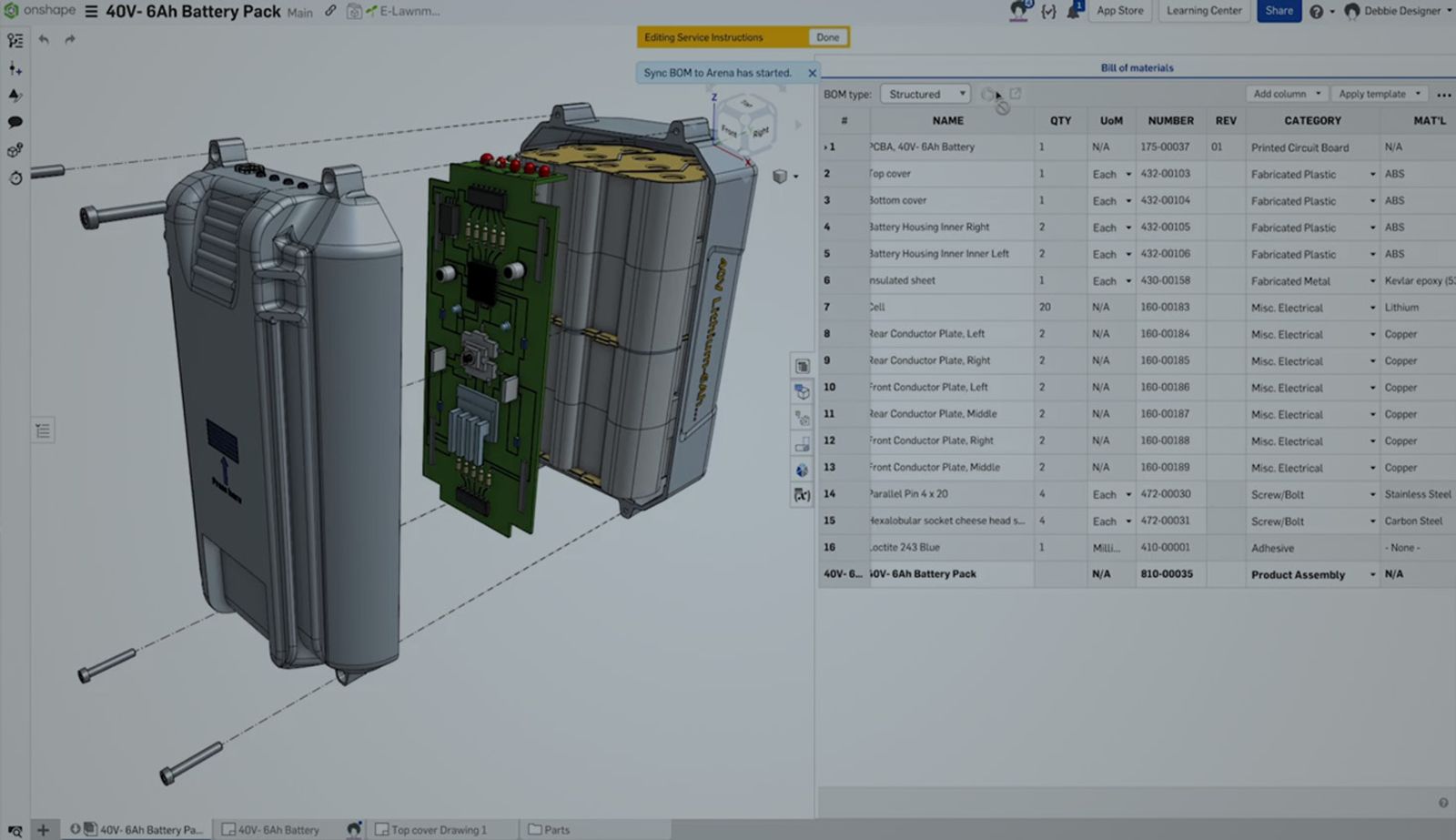

A Living, Breathing eBOM

In Onshape, the BOM is not a separate, exported document; it's an integral, dynamic part of the assembly environment. This solves the core problems of the traditional model instantly:

- Automatic, Real-Time Updates: Any modification made to the 3D model, whether changing a part, adding a component, or adjusting a quantity is instantly and automatically reflected in the eBOM. Manual data entry and the errors that come with it are completely eliminated.

- Built-in Version Control: Onshape's integrated data management automatically tracks every change, creating a comprehensive edit history. There is only one version of the design and its corresponding eBOM: the current one. This eliminates the risk of teams working from outdated information.

- Seamless Collaboration: Onshape was built for teamwork and collaboration. Multiple engineers can work on the same product simultaneously, and everyone sees the same BOM, updated in real time. This fosters the kind of collaborative, cross-functional environment needed to build a robust design.

Flexibility for Implementing Downstream Systems

When it's time to pass the eBOM data to downstream systems, Onshape's modern REST API-based architecture allows for seamless integration with the PLM and ERP systems that manage the MBOM. This creates the "digital thread"—an unbroken flow of data that ensures consistency from design all the way through to production. The Onshape-Arena Connection is one such integration. Many are possible.

The result is a dramatic reduction in the risks that plague traditional manufacturing:

- Minimized Rework and Scrap: Starting with a perfect eBOM prevents the procurement of incorrect parts and reduces assembly errors on the shop floor.

- Accelerated Time-to-Market: Eliminating manual data reconciliation and version control issues shortens new product introduction cycles.

- Enhanced Agility: A clean, digital process for managing the eBOM allows companies to implement design changes rapidly and efficiently, responding faster to market demands.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more