06:17

In architecture, there’s long been a disconnect between design and delivery. A staircase or built-in cabinet might start as a clean digital model, but it may have been redrawn several times by the time it reaches fabrication and installation, each step potentially introducing errors, delays, or compromises. For architects Rob Stiles and Sam Parsons, that friction became impossible to ignore.

“You’ve got three main players: the architect or designer, the fabricator, and the site team,” Stiles explains. “They all work from different versions of the same drawing, and every redraw erodes the original design intent.”

Determined to solve this disconnect, they founded Future Joinery Systems (FJS), which designs and produces bespoke joinery with a fully digital, screen-to-machine process. Based in the UK, FJS specializes in precision-made interiors: kitchens, staircases, and fitted furniture that marry architectural aesthetics with the efficiency of modern fabrication.

More than simply a manufacturer, FJS has designed a system that connects architects and makers through data, automation, and a shared digital model. PTC’s Onshape is a large piece of the digital engine that makes this possible.

Rebuilding the Tech Stack Using Onshape's Open API

In the UK construction industry, the handoff process between architects and manufacturing is particularly fragmented. Architects work in building information modeling (BIM) software, while joiners typically use manufacturing-oriented CAD or CAM tools. Each environment has its own uses, but they rarely speak the same language.

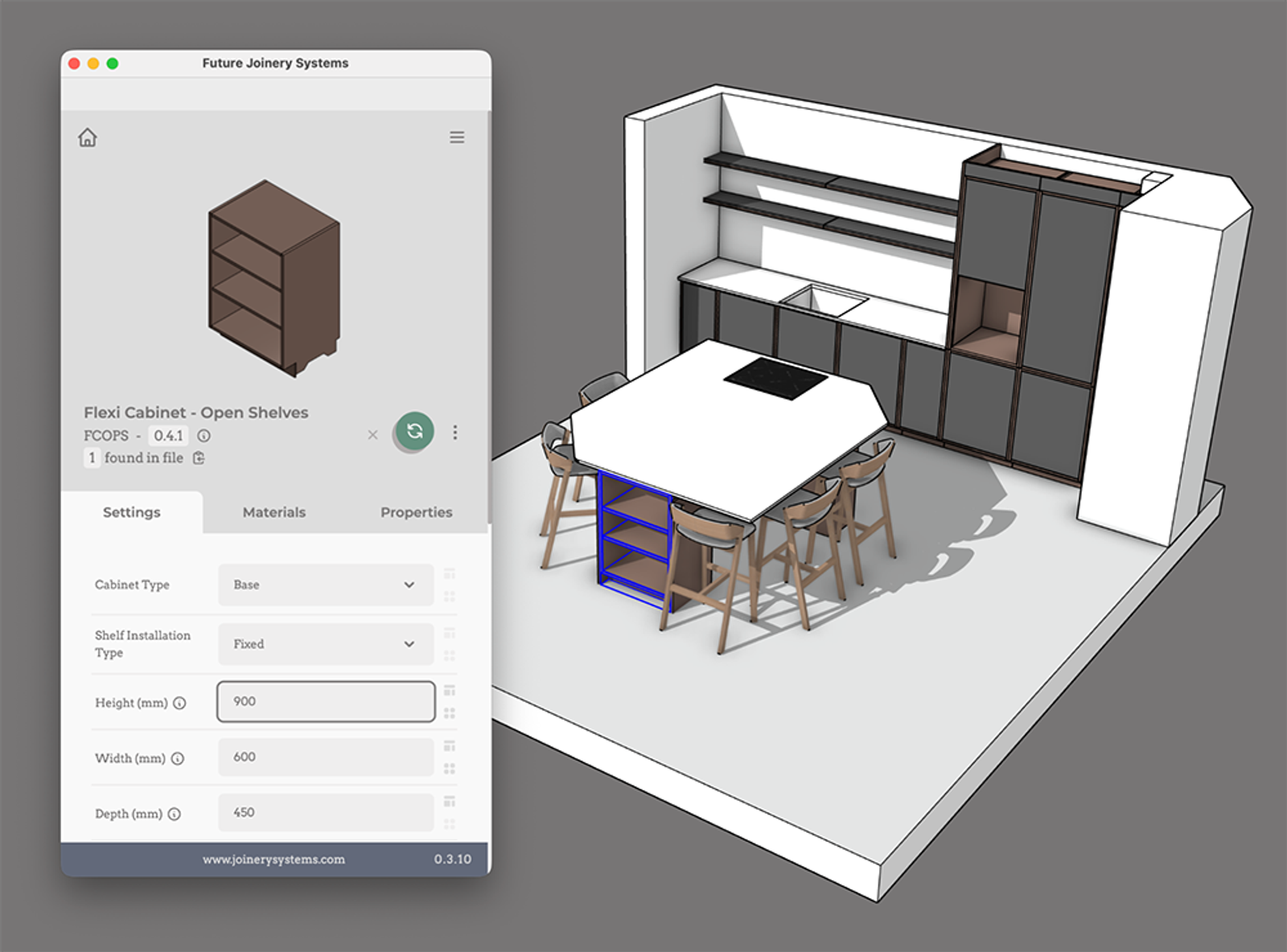

Stiles and Parsons wanted to close that loop by having architects configure joinery elements directly within the CAD model, using data-connected geometry that could flow straight to fabrication. But early prototypes still relied on multiple disconnected tools and manual data transfers.

“The moment we discovered Onshape, everything changed,” says Stiles. “It gave us a proper cloud modeler with an open API, and that meant we could finally build the stack the right way.”

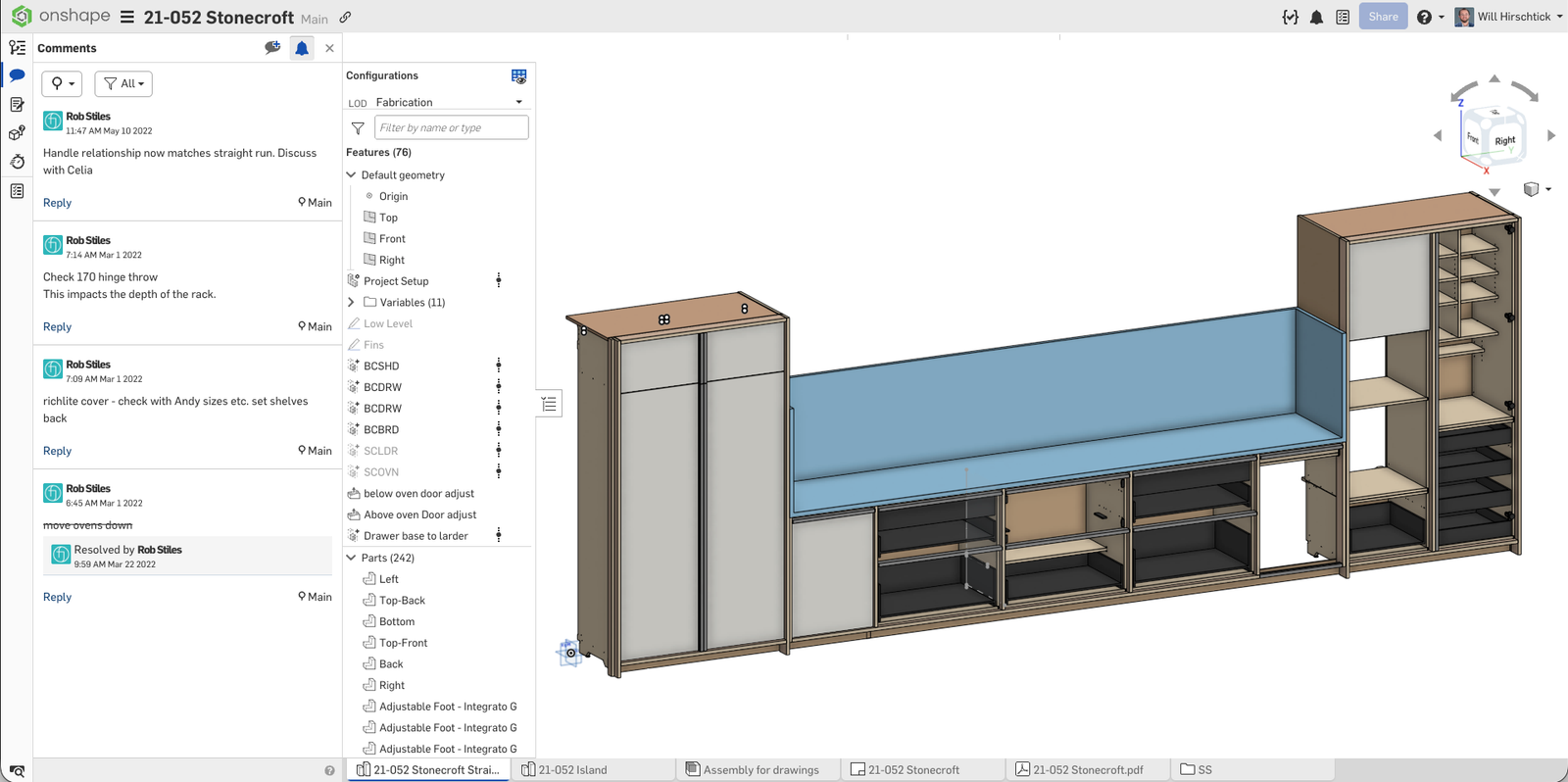

Cloud-native Onshape’s configurations and custom features let Parsons encode rules directly into geometry, capturing joinery intelligence like when a cabinet over 600 millimeters requires double doors or when a dado joint replaces a butt joint for strength.

“Most of what we do in Onshape isn’t just geometry,” says Parsons. “It’s domain knowledge. We’re teaching the model what’s possible.”

Onshape’s API integrations allow the team to connect designs to a configuration app they built for SketchUp and other BIM platforms. Within that interface, architects can design kitchens or staircases using intuitive controls, adjusting dimensions, materials, and fittings as needed.

Thanks to this integration, every adjustment in the configuration app is reflected instantly in Onshape, which builds the high-fidelity manufacturing model in real time. This means there’s no ambiguity between design and fabrication. When the architect finishes a configuration and clicks submit, Onshape rebuilds the model at full manufacturing detail and generates the files needed for CNC production. The data flows seamlessly into FJS’s CAM workflow, where toolpaths are automatically created for cutting, drilling, or milling. This eliminates redrawing, translation errors, and missing information.

“It’s all about maintaining that single source of truth,” says Parsons. “Instead of everyone modeling the same thing 10 different ways, we have one intelligent model that can serve every stage of the process.”

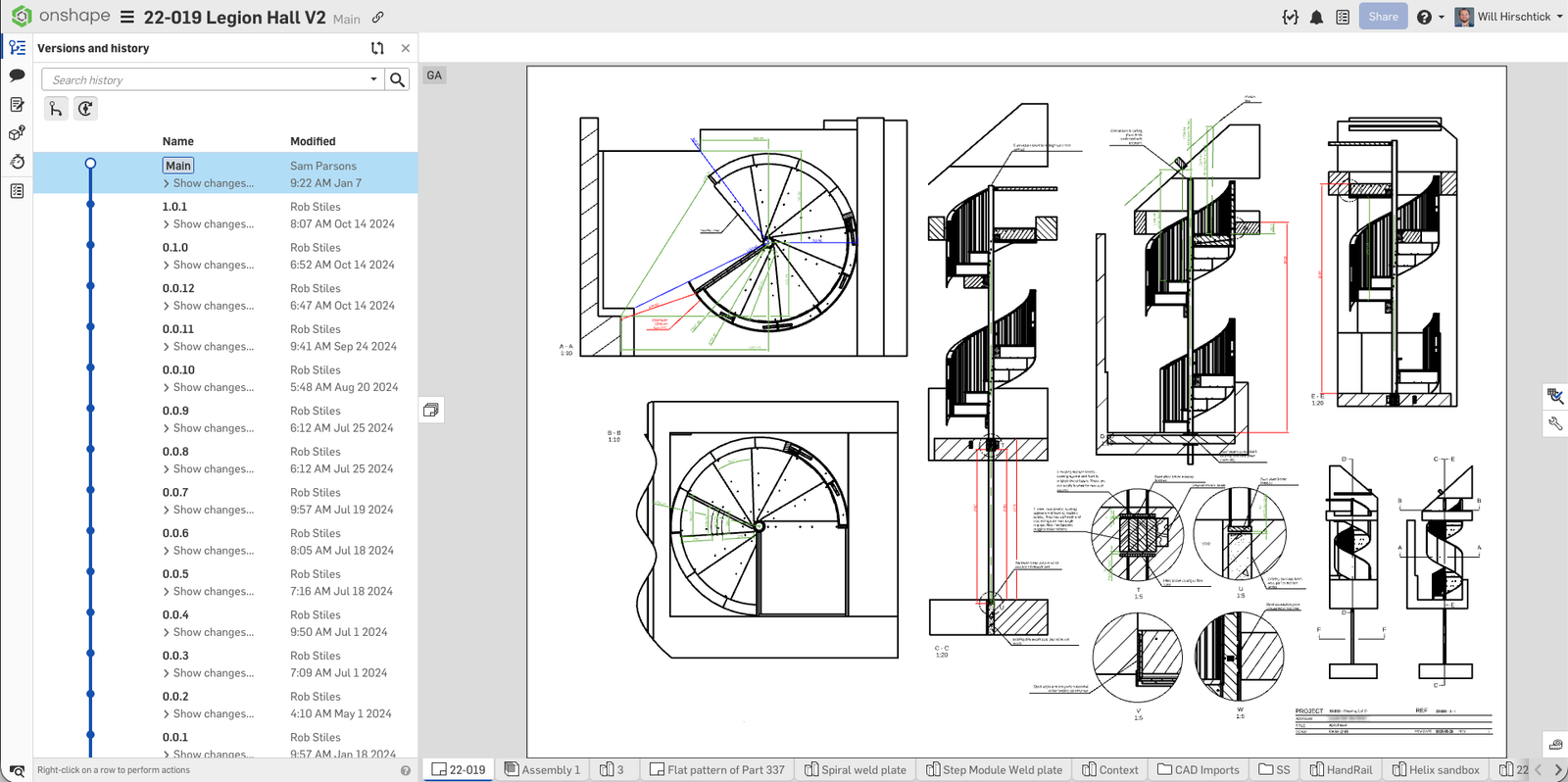

Fileless PDM Supports Clean Data to Safeguard Design Intent

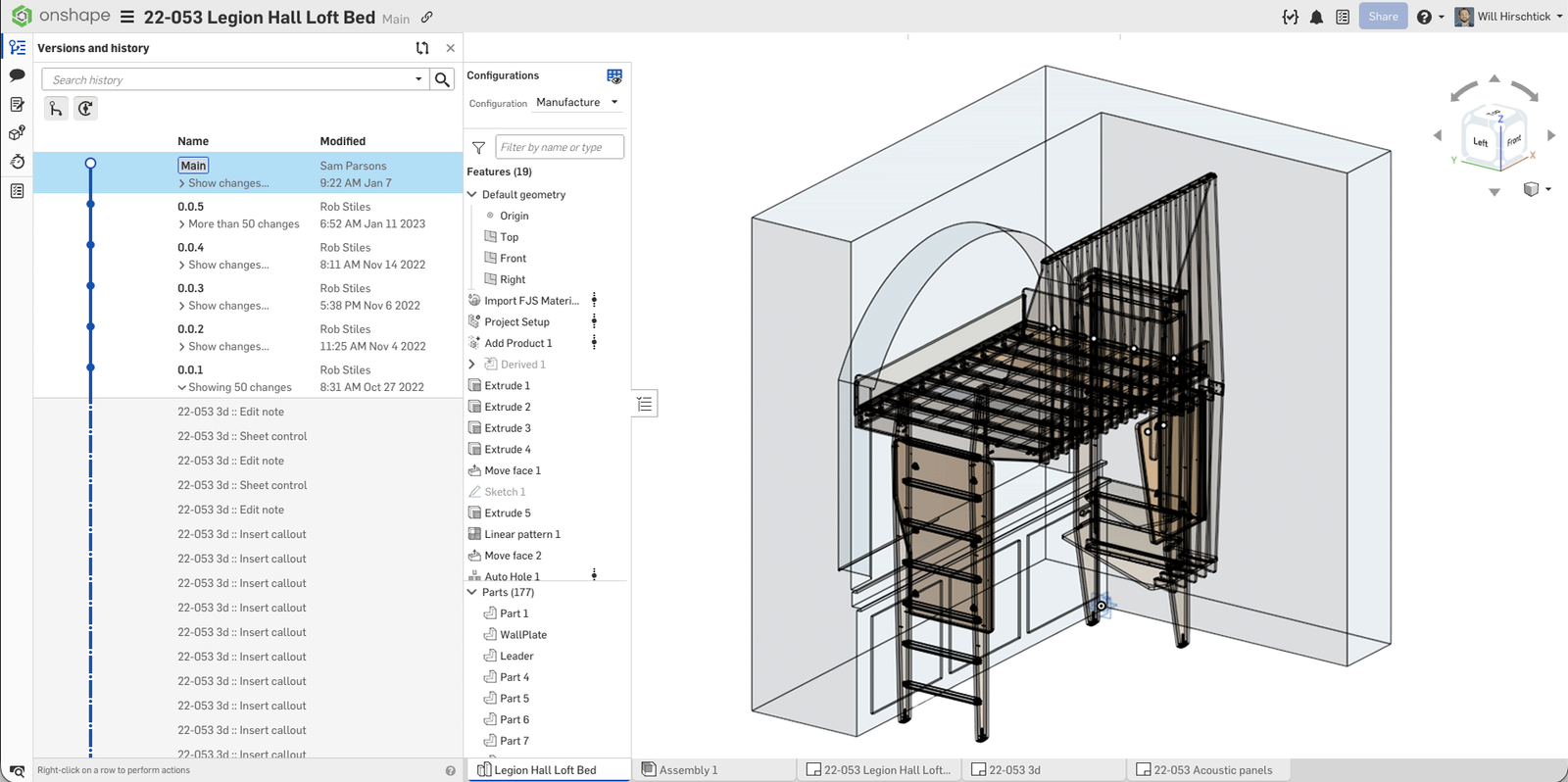

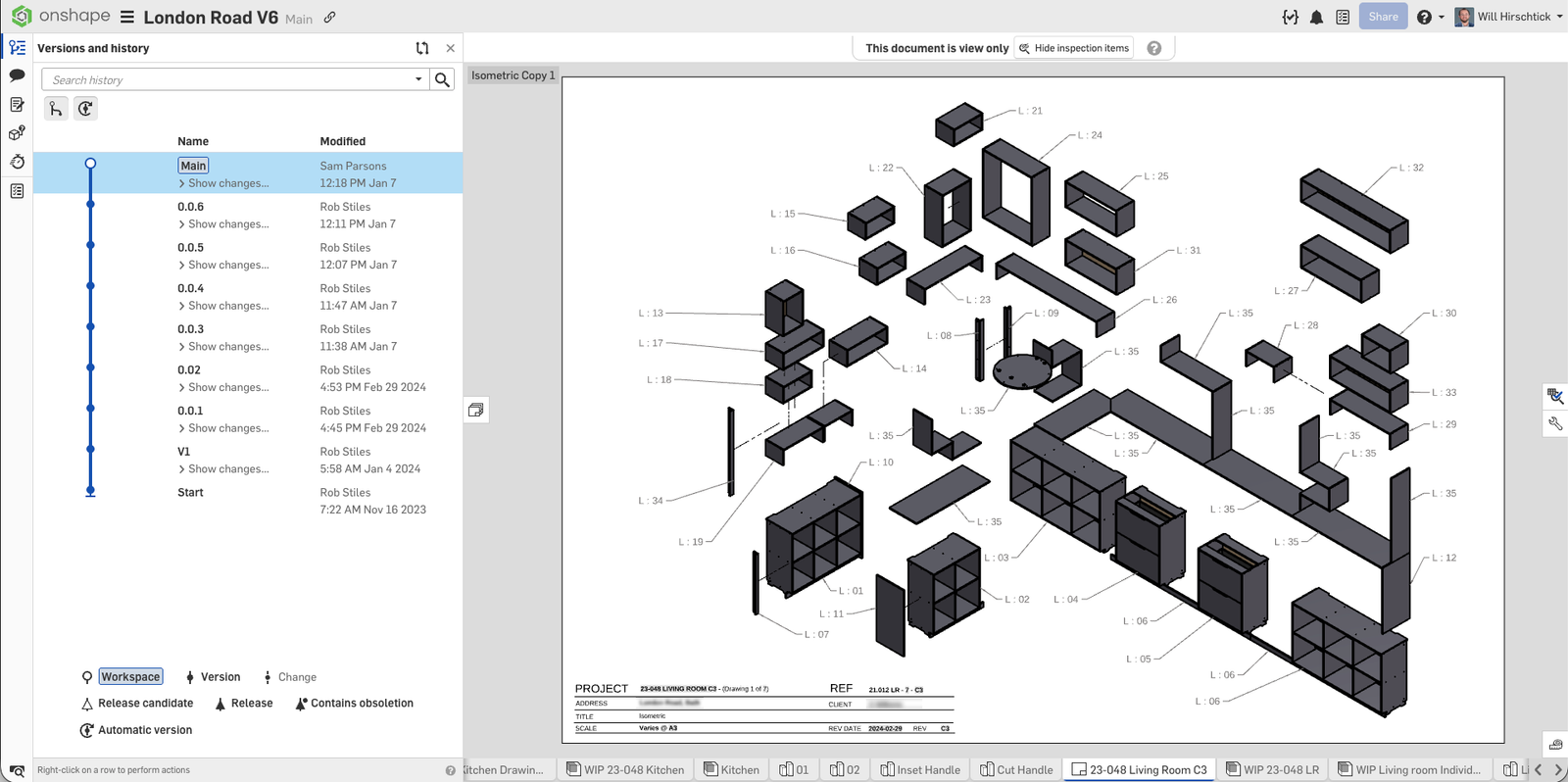

Every FJS component begins as an Onshape model and ends as a physical part, machined by a local fabricator. The team has automated much of that workflow with Onshape’s custom scripting tools, writing a FeatureScript that crawls each assembly, extracts every face, and outputs layered DXF files for CNC cutting.

“Most of our parts are made on 2.5-axis machines,” says Stiles. “They’re simple, accessible tools, but to make them efficient, you need clean, structured data. We built our exporter to tag every operation by type and depth, so the machinist immediately knows what’s what. They can use their own tooling strategy, but the geometry is bulletproof.”

The output can include hundreds of unique parts, all automatically labeled and nested. Because Onshape’s product data management (PDM) keeps the models version-controlled, FJS can trace exactly which configuration produced each component — a safeguard against costly errors.

Once cut, the panels are delivered onsite with digital assembly guides. Installers can open FJS’s custom web viewer, explore exploded 3D views, isolate parts, and even check the direction of wood grain.

“It’s better than drawings,” says Stiles. “They can see how everything fits together, and if they click on a hinge or fitting, there’s a link straight to the manufacturer’s video showing how to adjust it.”

A Single Source of Truth for Stronger Collaboration

In a legacy CAD environment, version control can feel like chaos. Files live on servers, emails multiply, and it’s often not clear which version is the right one. With Onshape, FJS has replaced that confusion with real-time, cloud-native collaboration. Onshape’s branching and merging workflows allow multiple engineers to iterate the same designs simultaneously, experimenting on options without fear of disrupting each other's work.

As ideas on different branches mature and become viable, they can be selectively merged back into the main design branch. This enables fair collaboration and ensures that the best design ideas win.

“The ability to branch and merge designs, to see every change and roll back instantly, it’s second nature now,” says Stiles. “We can send a link to anyone, and they’re in the model immediately. No installs, no exports.”

That accessibility has helped FJS grow its distributed manufacturing network. Fabricators across the UK can download the exact files they need and start machining immediately, knowing they’re working from the same data as the architect and the installer.

Because external systems can’t always handle the complexity of joinery-level geometry, FJS uses Onshape to manage multiple levels of detail. Simplified versions feed back into architectural models for coordination and pricing, while the high-resolution data stays in Onshape for fabrication.

“We can hold on to the manufacturing intelligence until the design is approved,” says Stiles. “Once the client signs off, it’s ready to machine.”

The Result: Designing Bespoke Joinery at Scale

Future Joinery Systems isn’t just building beautiful staircases and kitchens; they’re redefining how digital fabrication fits into architecture. Their Onshape-based workflow allows mass customization at scale: every project is unique, yet every component is governed by the same data structure.

“It’s about making the bespoke repeatable,” says Parsons. “If it can be made with a CNC machine, we can model it in Onshape, configure it, and manufacture it.”

Their approach has already earned recognition in the UK design community. Machined directly from Onshape data, their Brockeridge Staircase won the interiors category in the 2020 Wood Awards, which “recognises, encourages and promotes outstanding wood design, craftsmanship and installation.”

But for the founders, the bigger success is philosophical. “We came from architecture, not engineering,” says Stiles. “We just wanted a better way to get from idea to reality. Onshape gave us the foundation to make that possible.”

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more