03:18

You might already be using variables in your Onshape Part Studios to make your models easier to edit. But if you're stopping there, you're missing out on some of Onshape's most powerful capabilities.

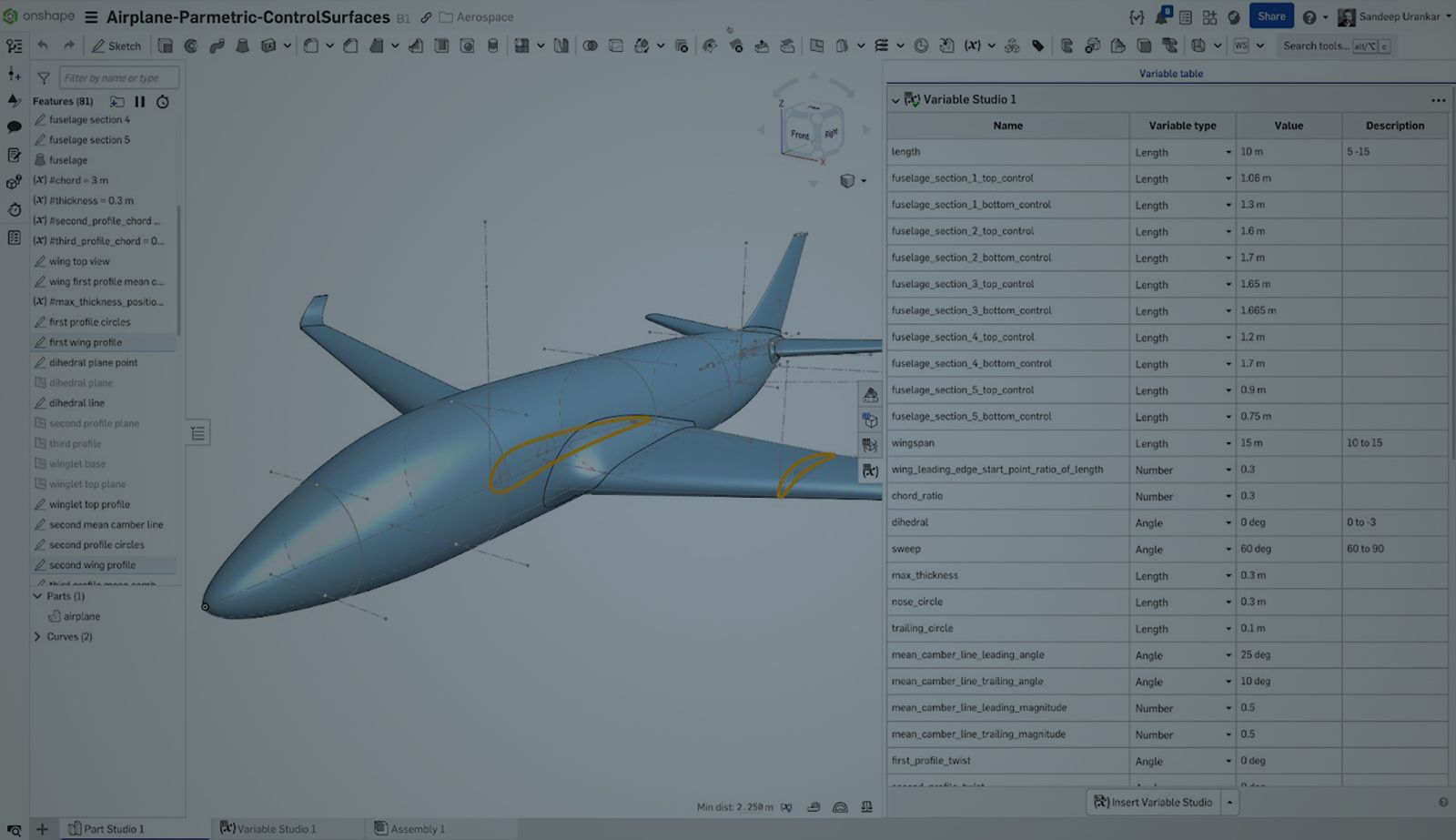

Variable Studio: Your Global Parameter Document

A standard variable lives inside a single Part Studio. A Variable Studio is a dedicated, separate Onshape document that is intended to hold variables or parameters.

By creating a Variable Studio, you can define all your critical dimensions and parameters in one central location. This could include standard material thicknesses, common hole sizes, specific clearances, or key product dimensions.

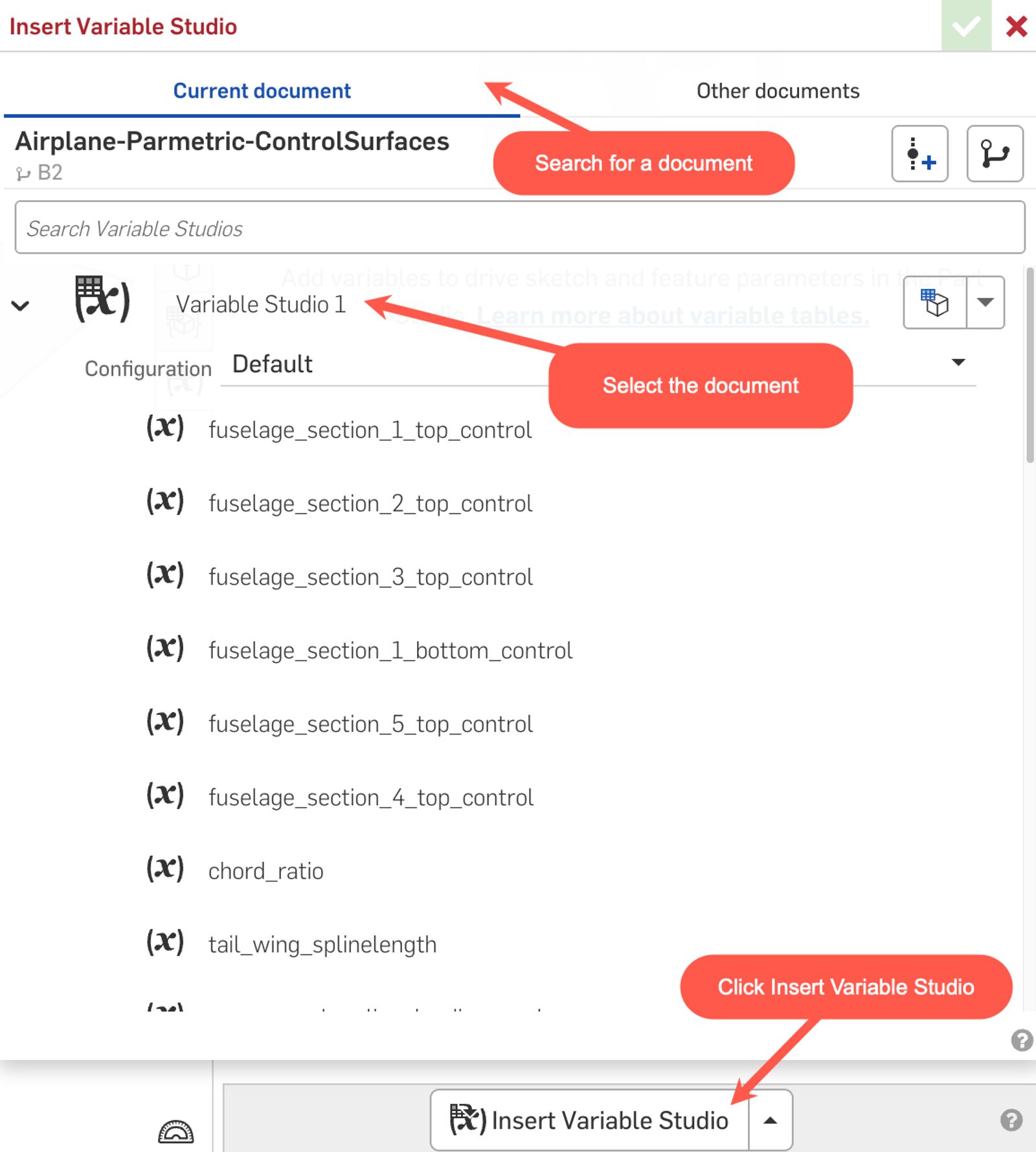

To use these global variables, you simply link your Part Studio to the Variable Studio.

Advantages of Globally Managed Variables

The benefits are huge, especially for teams and complex projects.

Centralized Updates: Need to change a standard dimension across an entire product line? Instead of opening and editing dozens of documents, you update one value in the master Variable Studio. Every linked document will instantly reflect the change when updated.

Simplified Management: It separates your design intent from your geometry. The Variable Studio contains the "what" (the dimensions), while your Part Studios contain the "how" (the features). This makes models cleaner and easier to understand. Helping capture more of the design intent.

Consistency Across Projects: Ensure every designer on your team is using the exact same value for standard components, like screw clearances or material gauges. No more guesswork or variation between documents.

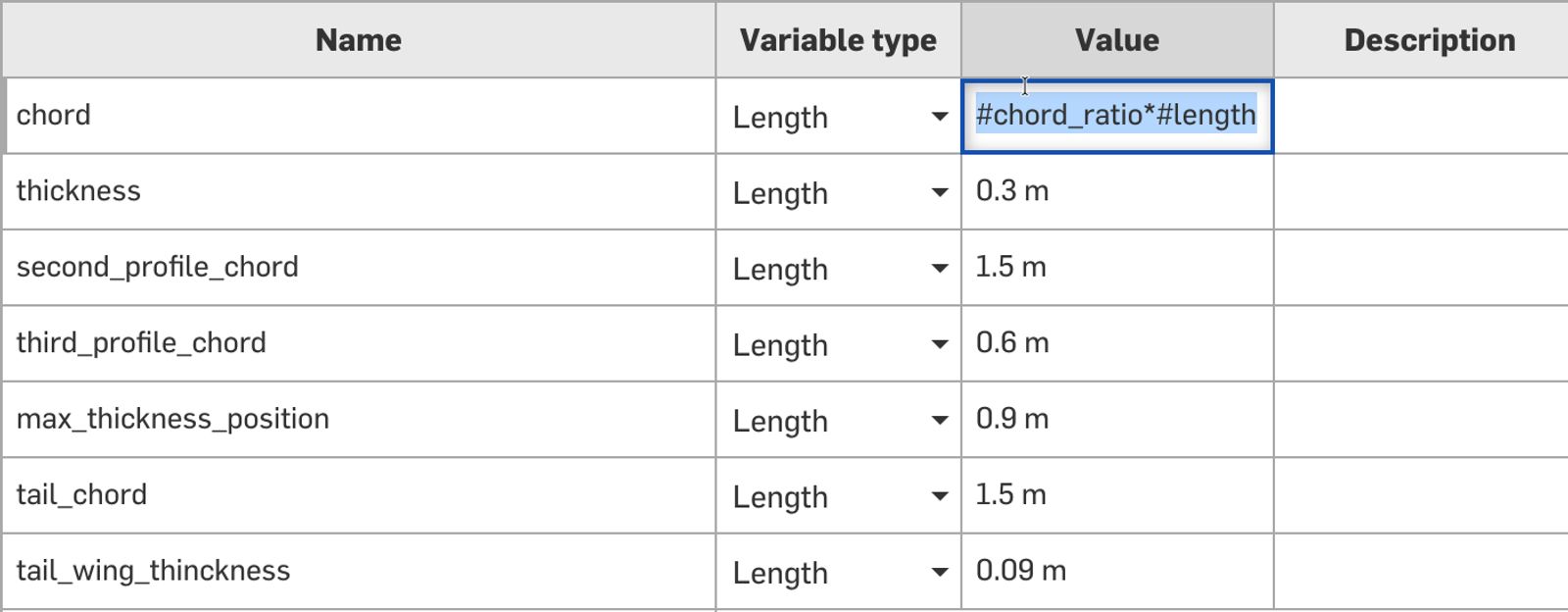

Unlocking Design Rules with Formulas

This is where your models start getting really smart. Onshape variables aren't limited to static numbers, they can be defined using mathematical formulas and can even reference other variables.

This allows you to build design intent directly into your model. Instead of setting three separate dimensions, you can define relationships between them.

For example:

- Chord = #chord_ratio * #length

- Thickness = #chord * 0.1

- tail _chord = 0.5 * #chord

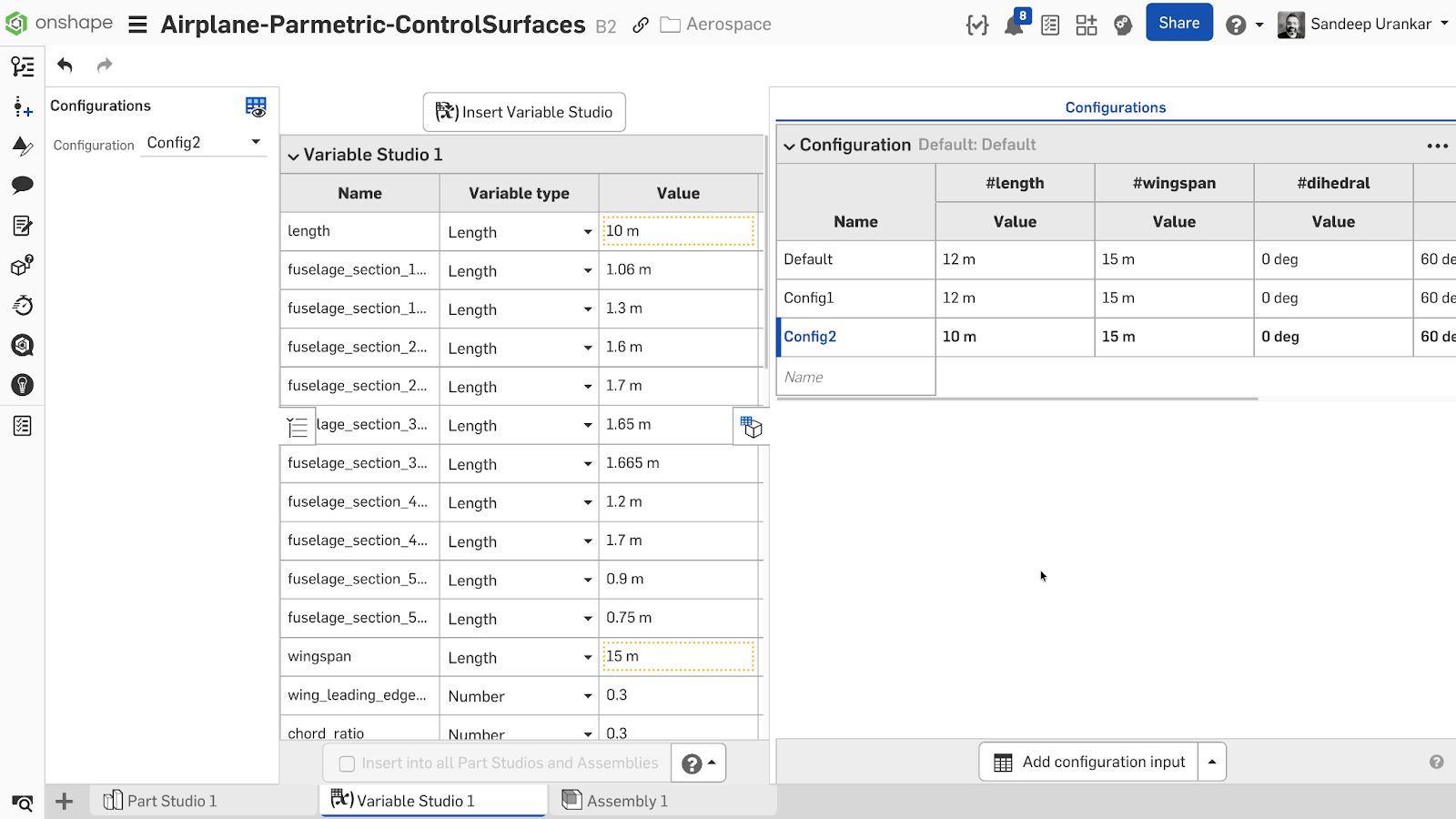

Driving Configurations with Variables

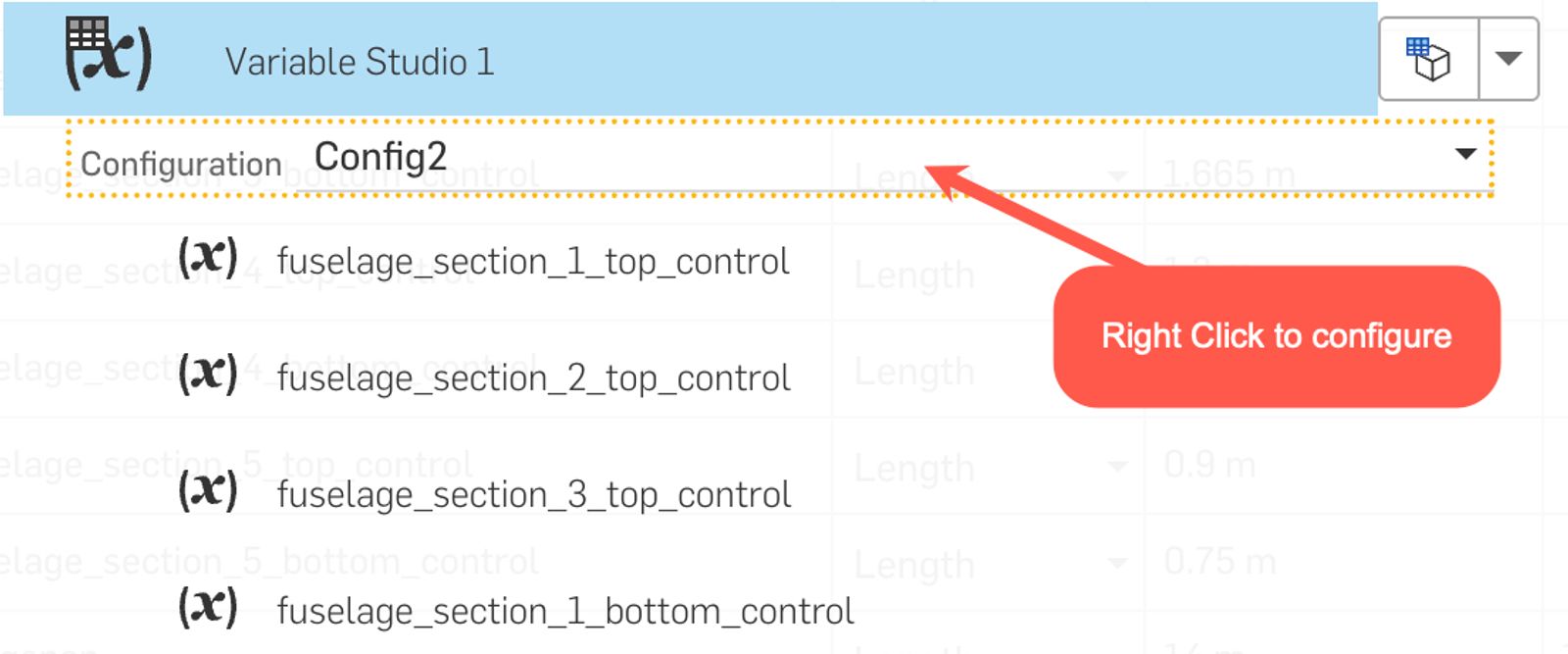

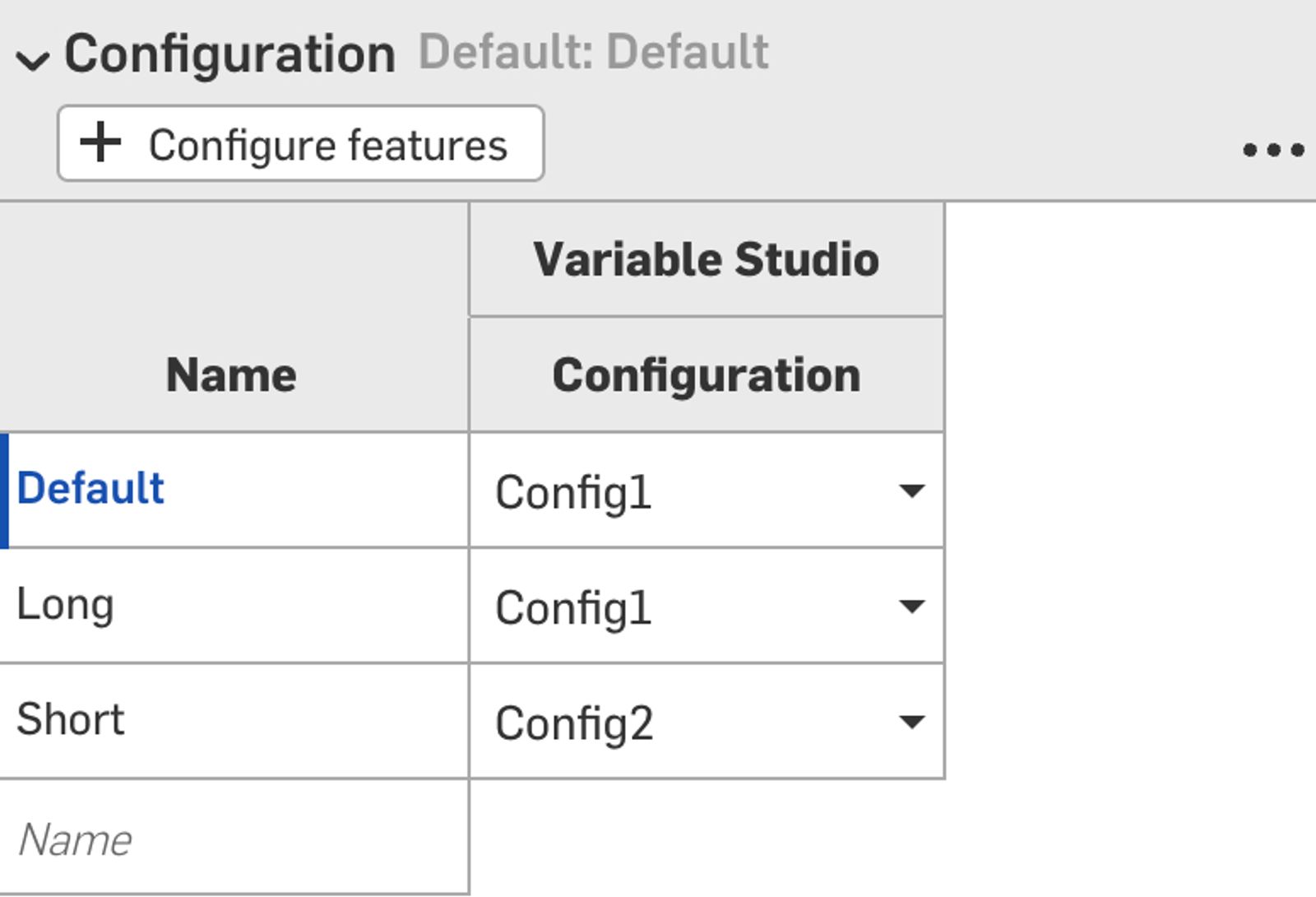

Configurations allow you to create families of similar parts within a single Part Studio. Variables are the perfect tool to drive them. Instead of manually creating and editing dimensions for each configuration, you can control everything with one or more variables. Here's a simple workflow:

- Create a Variable: Start by creating a variable that will control the part variation, for example, #Length.

- Configure the Variable: In the Configuration panel, add your variable as a "Configuration Variable." This exposes it as a dropdown list or input field.

- Define Your Options: List the different values your variable will take for each configuration

- Drive Dimensions: In your sketches and features, set key dimensions to equal your configuration variable (e.g., set your extrude depth to #Length).

- Configure the Configuration: This exposes the configured studio as configuration in a part studio.

Now, when you select an option from the configuration dropdown (e.g., "Short," "Medium," "Long"), the #Length variable changes, and your model's geometry updates instantly. This is an exceptionally clean and efficient way to manage different sizes, versions, or states of a design.

Building Robust Designs with Query Variables

Query variables in Onshape are a powerful new feature that lets you create parametrically-defined selections that automatically update as your model changes. Instead of manually selecting geometry (such as faces, edges, or bodies) for operations like chamfers, extrudes, or booleans, you create a query variable – a selection rule – which then automatically finds and includes the required geometry.

This can be based on entity types (edge, vertex, face, body), location, relationships (e.g., parallel edges, faces made by certain features), or even custom logic written with custom features.

Discover Powerful Parametric Design with Onshape

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more