00:00

In northern Indiana, Janus Motorcycles is doing something radical: building lightweight, handmade motorcycles in the U.S. — designed entirely in the cloud.

Founded in 2011 by vintage moped enthusiasts, Janus has grown from a two-person restoration project to a company with 30 employees, a dedicated fanbase, and a mission to recapture the joy and simplicity of motorcycling’s past.

With five current models (the Gryffin 450 and 250, Halcyon 250 and 450, and Phoenix 250), Janus bikes are intentionally small by modern standards.

“We wanted to make something that felt approachable,” says CEO, founder, and lead designer Richard Worsham. “A lot of bikes today are big and heavy, which can be intimidating for new or casual riders. We were more inspired by the classics—lighter bikes from the early 1900s that were about connection and craftsmanship.”

That craftsmanship-first philosophy extends beyond the showroom. Janus designs and builds most of its components in-house or locally in Elkhart County, a region known for its robust manufacturing ecosystem.

“We’re surrounded by fabrication shops and suppliers. It makes it possible for us to keep everything close—both literally and in terms of quality,” Worsham says.

But designing a motorcycle from scratch, let alone one that’s handmade and small-batch, comes with engineering challenges. That’s where PTC’s Onshape comes in.

Cloud-Native CAD Built for Flexibility & Collaboration

Janus began using Onshape in 2017, looking for a powerful, cost-effective alternative to traditional desktop CAD.

“Honestly, we chose it at first because it was affordable,” Worsham says. “But over time, we realized how much more it could do.”

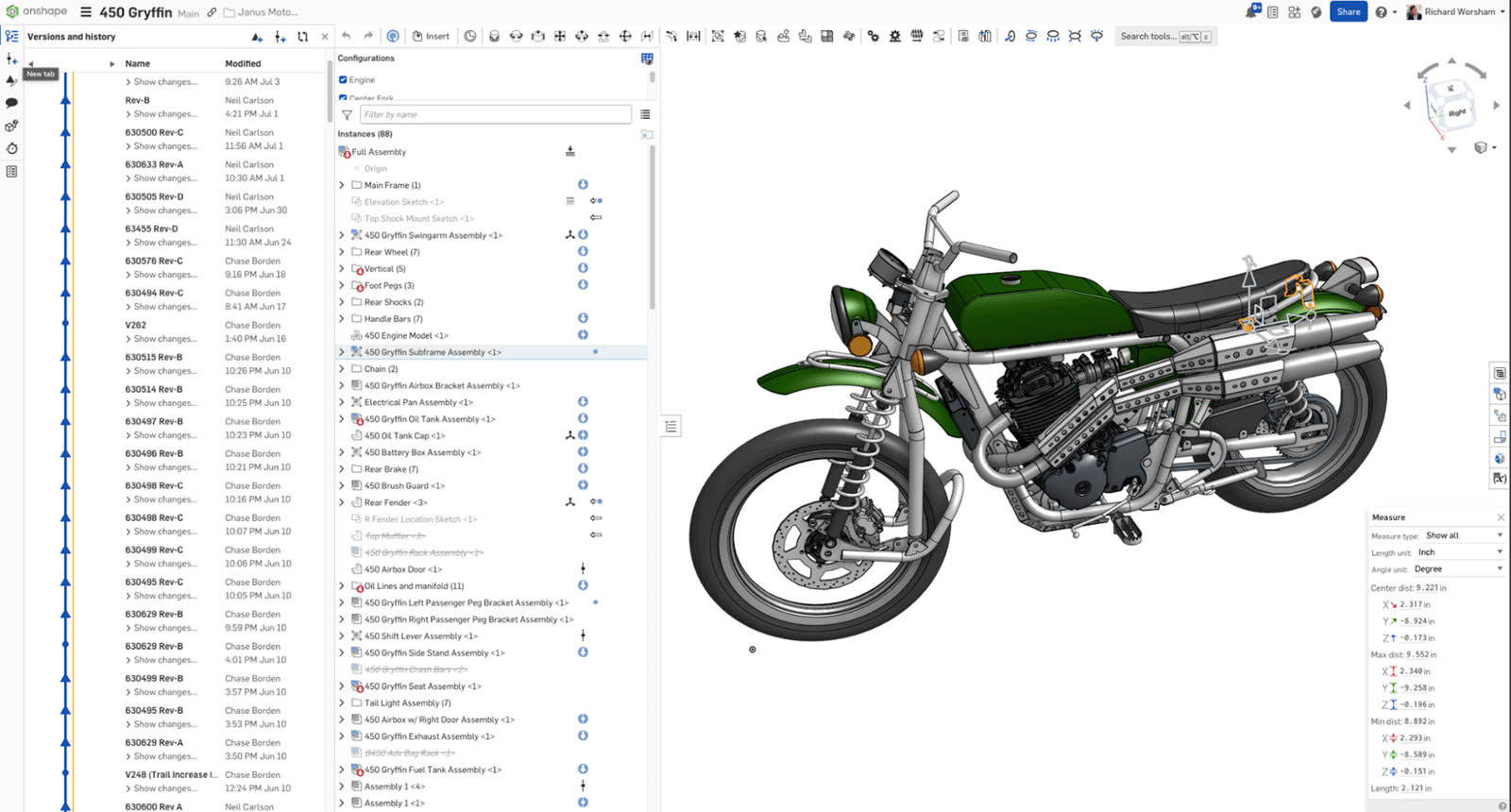

Now, the Janus team relies on Onshape’s cloud-native CAD and PDM platform to manage everything from 3D models and manufacturing prints to revision control and supplier communications.

“The setup was super easy,” says Neil Carlson, Design Manager. “You don’t have to install anything. It’s secure, it works across all our machines, including Linux, and we never worry about losing files or needing a server.”

That flexibility is essential for a small team. Users collaborate daily on tooling, components, and product improvements directly in Onshape, even if they’re working from different machines or locations.

“It’s great to be able to just pull up the same document from home and keep going,” Carlson says.

Modern CAD Conveniences Meet Classic Design

As Janus has scaled production, Onshape has played a growing role in helping them improve design efficiency and manufacturability.

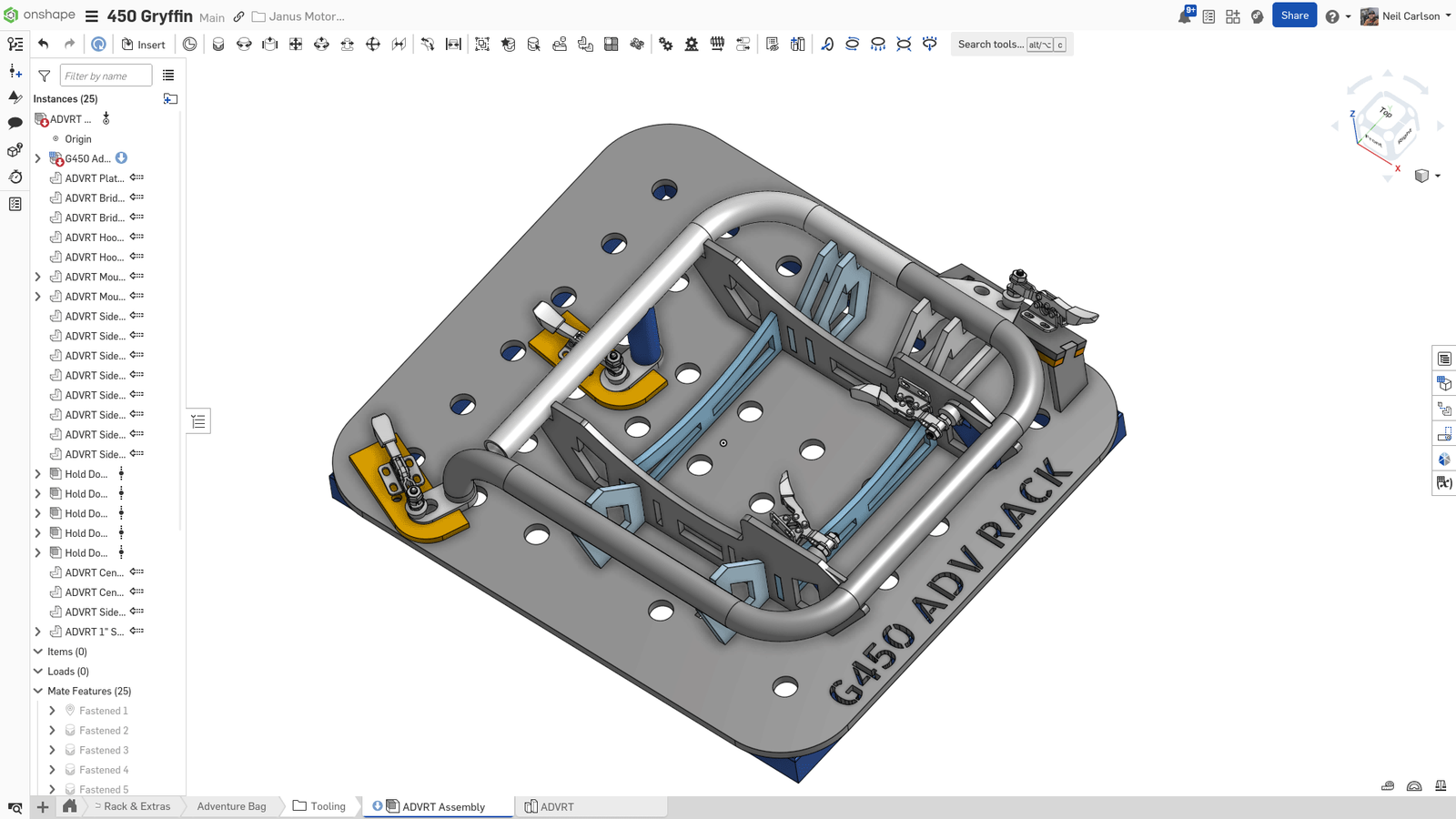

Design Engineer Chase Borden, who has worked for many years in other areas of the business, currently sits on the design team modeling custom jigs and tooling to streamline welding and assembly.

“A lot of our older fixtures were built by hand, and they weren’t always consistent,” Borden says. “Now we’re building them digitally from the start, which saves us time and improves accuracy.”

Because Onshape automatically tracks every design change and version, the team can confidently iterate and share designs with suppliers without worrying about misalignment or file errors.

“We use Onshape to generate both our prints and 3D models for vendors,” says Worsham. “The revision tracking is incredibly helpful. If something changes, we can always trace it back, compare versions, and make sure everyone’s on the same page.”

Building a Niche Market from the Ground-Up

Janus doesn’t just build motorcycles; they’re building a new category.

“There’s not really anyone doing what we’re doing,” Worsham says. “These bikes aren’t budget bikes, and they’re not Harley-style cruisers either. We’re creating a new space for small, hand-built, American motorcycles.”

Their target customer? Often seasoned riders who already own bikes and appreciate something one-of-a-kind.

“We get a lot of people who have Harleys or Royal Enfields,” says Borden. “But they’re looking for something unique—something they can ride for the fun of it and work on themselves.”

Janus sells direct-to-consumer through its website, YouTube channel, and social media. Their visual storytelling, craftsmanship, and design-first identity have helped them stand out, and Onshape plays a part in that, too.

“We don’t use Render Studio yet, but we export Onshape models for marketing renders and our online configurator,” Worsham says. “It’s just another example of how versatile the platform is for a small team like ours.”

Designing for Growth and Quality with Cloud-Native CAD

With ambitious growth plans ahead, Janus is focused on expanding production without sacrificing what makes their bikes special. That means continuing to work in Onshape to refine manufacturing processes, onboard new team members, and build better tools to support the next era of hand-built American motorcycles.

“Onshape has worked for us from the beginning,” Worsham says. “It saves us time, it keeps us organized, and it lets us focus on what we love—building bikes.”

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more