02:37

When it comes to designing parts for manufacturing, especially those destined for injection molding, die casting, or other high-precision processes, wall thickness isn’t just a detail; it’s a dealbreaker.

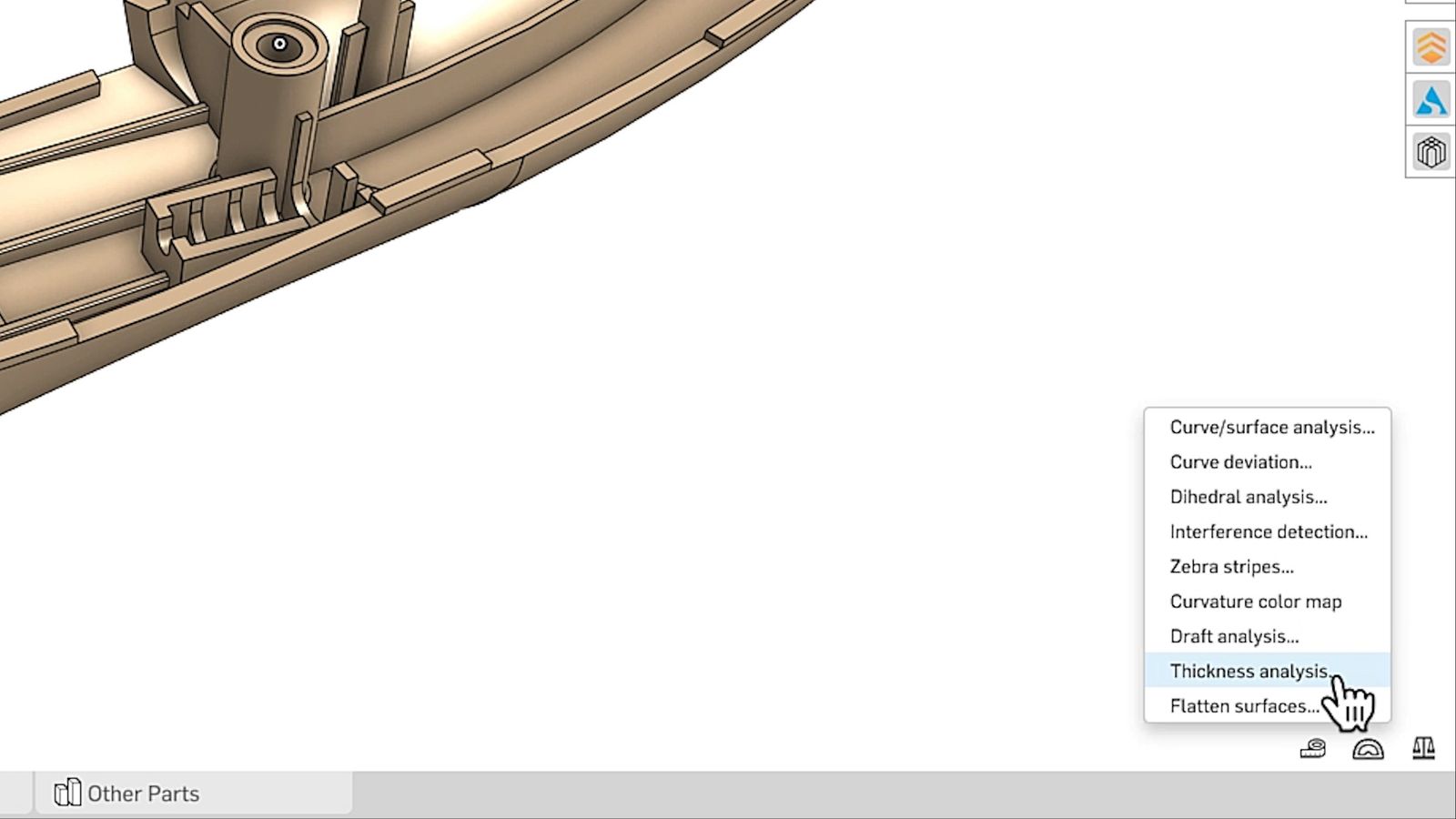

Too thick? You risk sink marks, warpage, and long cooling times. Too thin? You might face short shots, flow lines, or structural failure. That’s why Onshape’s Thickness Analysis tool is a game-changer for engineers and designers who want to get it right the first time.

Why Thickness Matters

Whether you're designing plastic enclosures, metal castings, or consumer packaging, uniform wall thickness is key to:

- Durability: Avoid weak spots and stress concentrations.

- Manufacturability: Prevent defects like warpage and sink marks.

- Efficiency: Reduce cycle times and material waste.

The Onshape Advantage

Unlike traditional CAD tools, Onshape’s cloud-native platform lets you run thickness analysis instantly – without plugins, installations, or waiting for IT. And because it’s built into the Part Studio, you can analyze multiple parts simultaneously and keep designing while the results process in the background.

Four Powerful Methods, One Seamless Experience

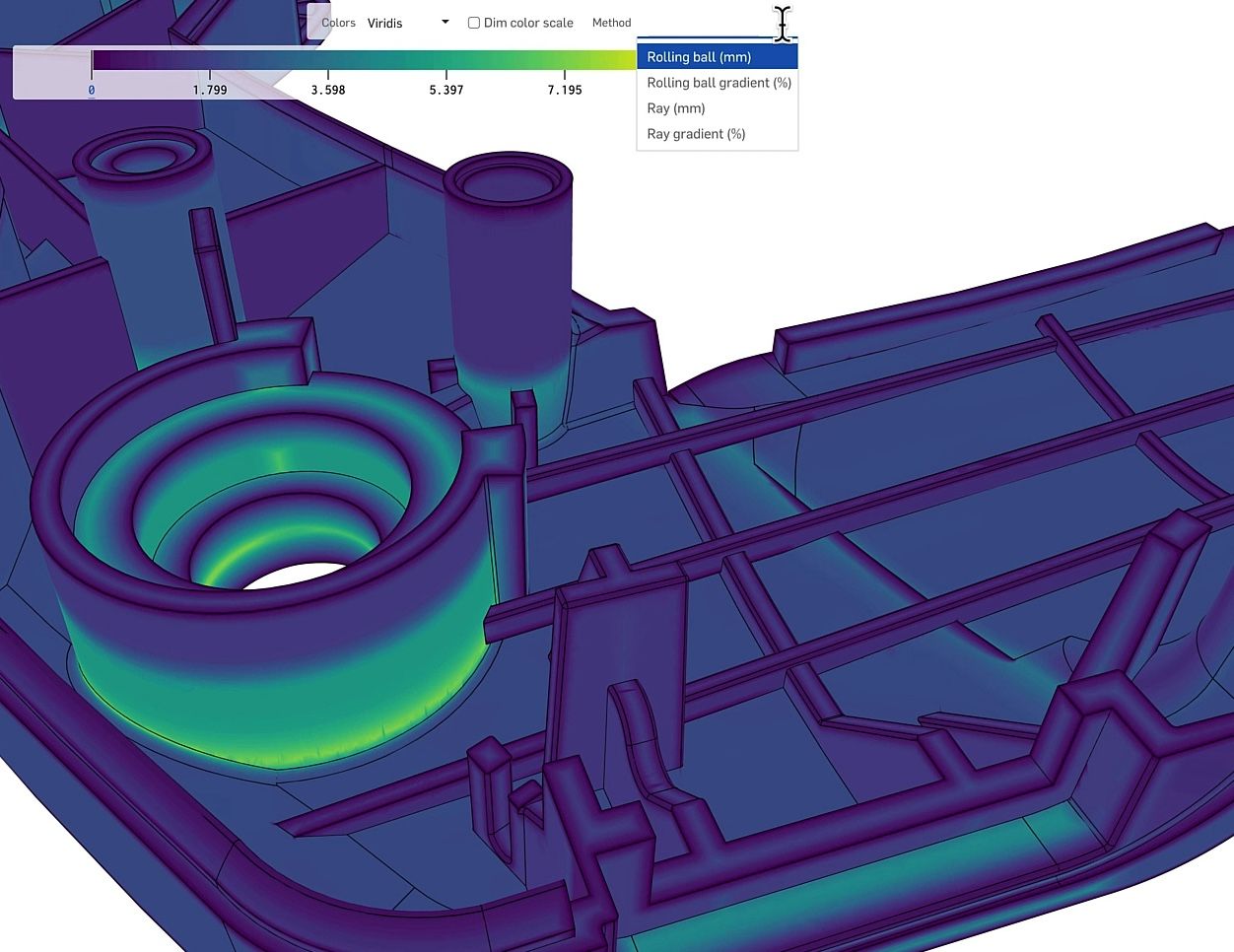

Onshape offers four distinct ways to measure thickness, each suited to different design challenges:

- Ray Method: Fires a ray normal to each face and measures the distance to the next wall. Ideal for thin features like ribs and flanges.

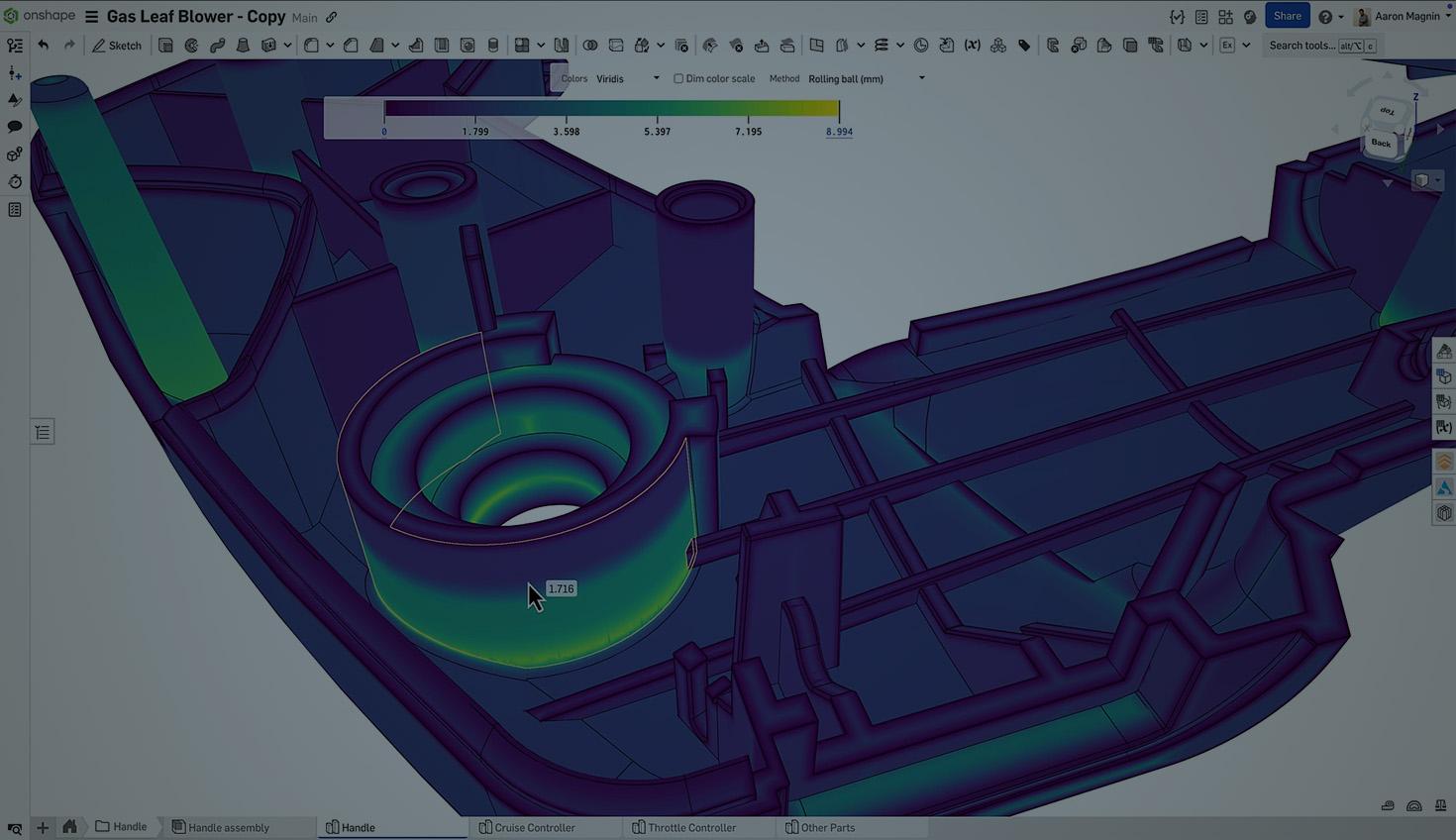

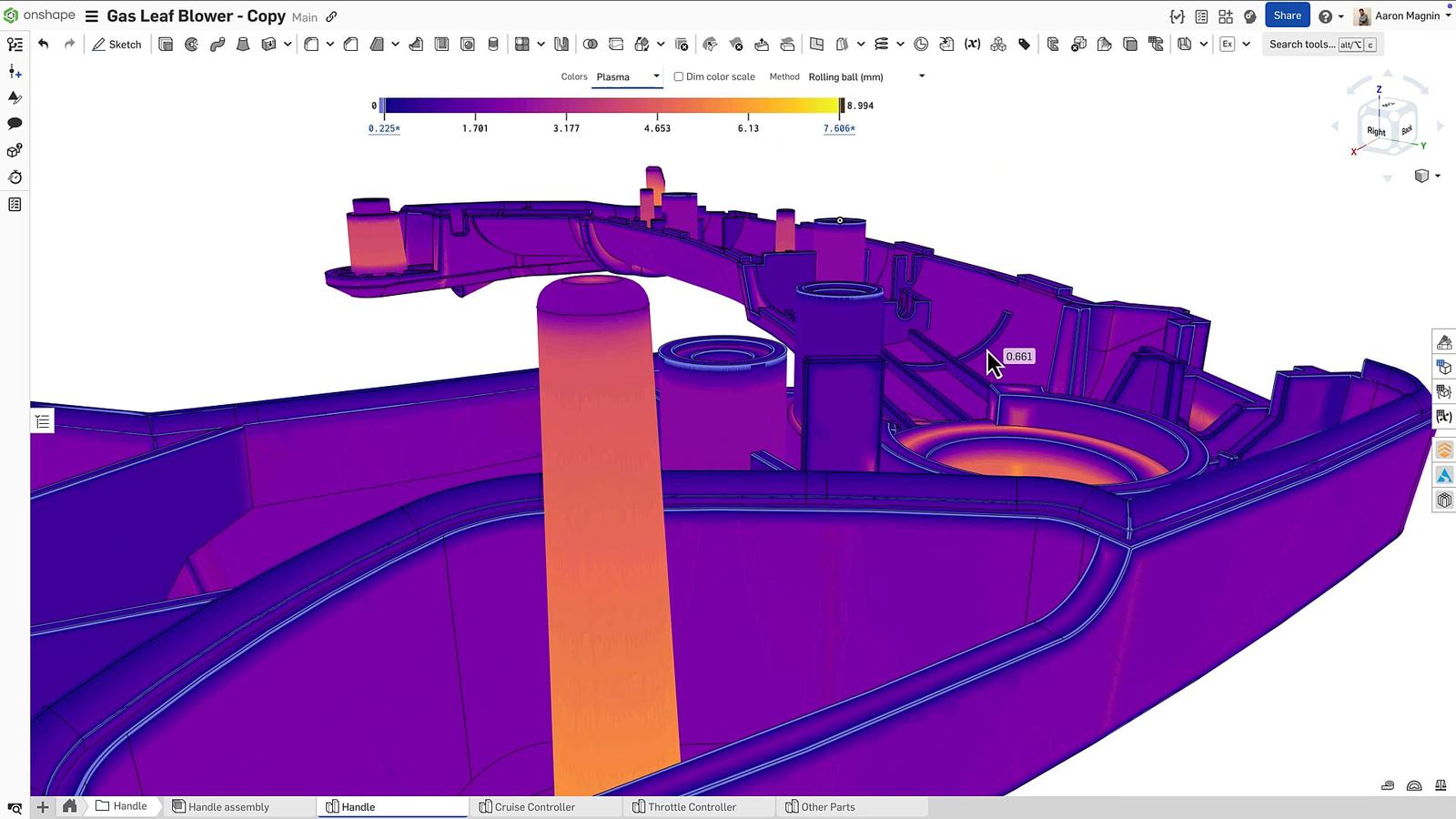

- Rolling Ball Method: Calculates the largest sphere that fits inside the part at each point. Great for complex internal geometries and continuous thickness mapping.

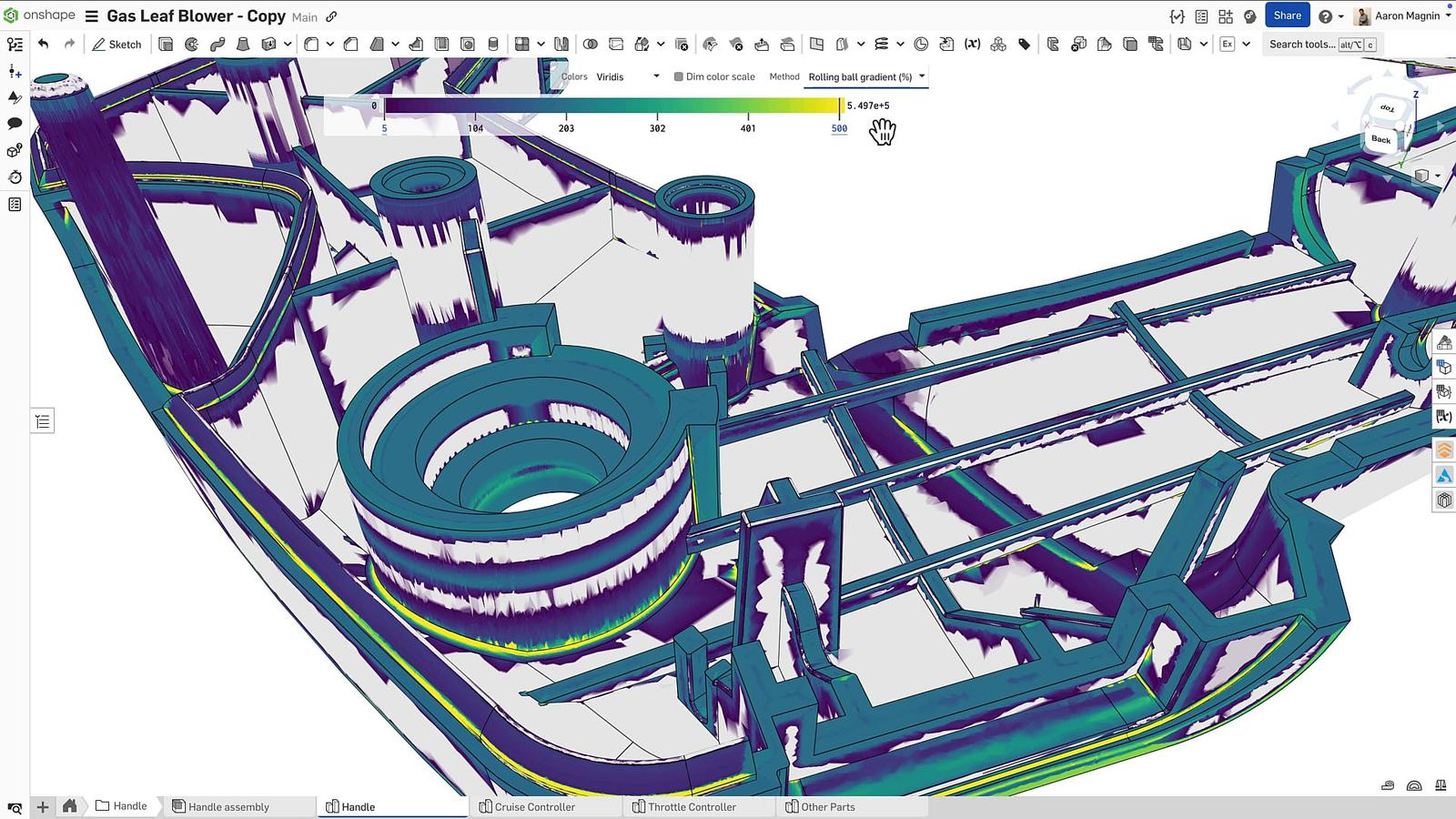

- Gradient Methods for Ray and Rolling Ball: Measures how quickly thickness changes for both of the above – critical for spotting areas prone to warpage or short shots.

Visual Feedback That Drives Better Decisions

Color-coded results make it easy to spot problem areas. Zoom in on red zones to see where thickness drops to zero, or adjust the scale to highlight regions below a certain threshold. The display is persistent, so you can use it as a live guide while editing features.

Real-Time Iteration, Real-World Impact

With Onshape’s Thickness Analysis, design iteration becomes an interactive experience. As you tweak features – whether it's thinning out a rib, thickening a boss, or reshaping a flange – the analysis updates instantly, showing intermediate results without waiting for full refinement. This means you can validate changes on the fly, reducing guesswork.

With the tool built directly into the Part Studio, you don’t need to switch tabs or jump into a "utility". You can analyze multiple parts at once, which empowers engineers to make smarter decisions earlier in the design process, accelerating time to market and reducing costly manufacturing errors.

It’s a major leap forward compared to traditional CAD tools, where analysis is slow, limited to single parts, or requires special utilities.

Better Products, Faster

With Onshape’s Thickness Analysis, you’re not just checking boxes – you’re designing with confidence. Whether you're optimizing for strength, manufacturability, or speed, this tool helps you make smarter decisions earlier in the process.

That’s the Onshape Advantage.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more