04:29

As 3D printing transforms from a prototyping novelty into a cornerstone of modern manufacturing, the limitations of conventional 3D modeling software become increasingly apparent. While basic modeling tools can produce simple prints, professional manufacturing environments demand the comprehensive capabilities that only 3D CAD systems can deliver.

Below, we will explore what you should look for in your 3D CAD software to support 3D printing workflows, and how Onshape, PTC's cloud-native CAD and PDM platform, delivers these capabilities through a modern, purpose-built architecture designed for today’s engineering challenges.

CAD Software for 3D Printing Should Have…

…Powerful Parametric Capabilities

Professional 3D printing applications require parametric capabilities that maintain design intent while enabling rapid modifications. Onshape’s parametric modeling system provides these capabilities through a modern interface with unique configuration features. This allows engineers to create families of related parts optimized for different 3D printers, materials, or end-use requirements – all from a single base model.

…Streamlined File Format Handling

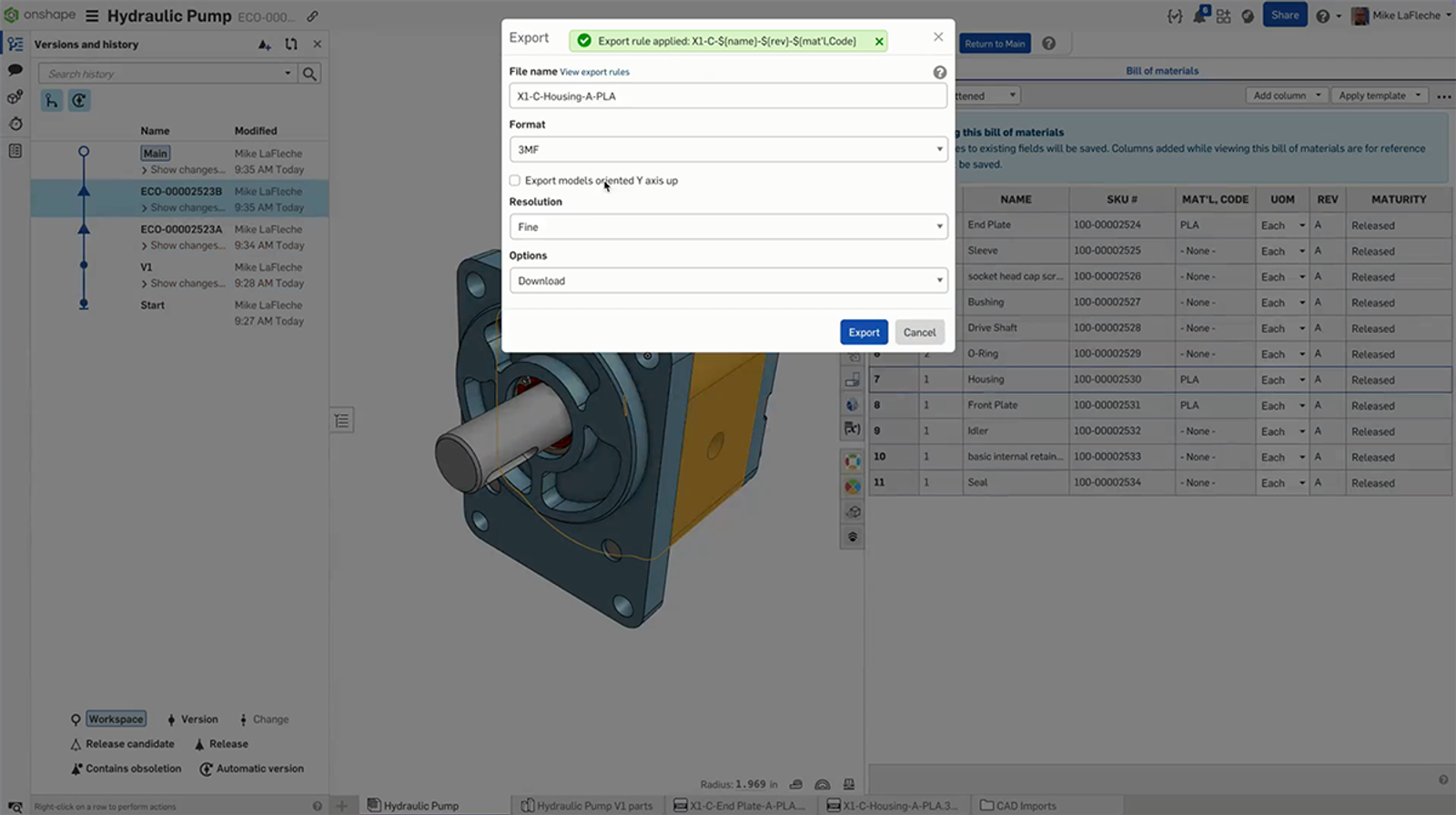

Exporting 3D models to STL or 3MF formats in Onshape is straightforward – just right-click, select "Export," and choose your desired settings. What distinguishes Onshape is its automated file naming system, which can enforce consistent conventions across teams, embedding critical metadata like part numbers, printer designations, and material choices. Other formats for export are also available, like STEP, if your printer slicer supports that.

Tech Tip: Using STL vs 3MF Files in Onshape for Additive Manufacturing

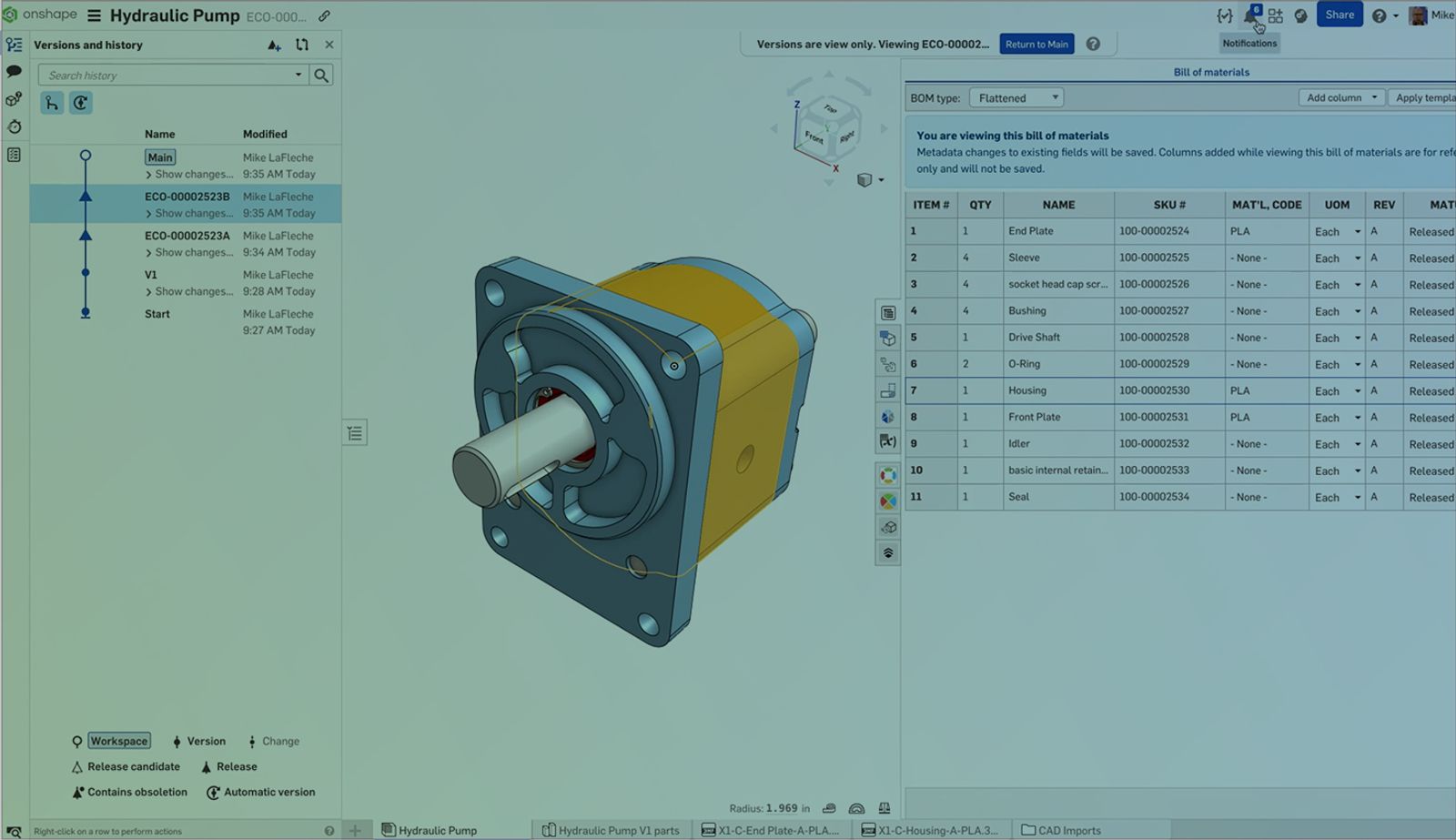

…Revision Management for Rapid Iteration

3D printing thrives on iterative development, but traditional file-based CAD creates version control nightmares with each iteration. Onshape's database-driven architecture maintains a single source of truth with comprehensive edit history, eliminating file management overhead.

Companies like Omnirobotic leverage this capability for rapid prototyping of housing components for their robotic camera systems, quickly iterating designs through 3D printed prototypes before final aluminum production.

…Real-Time Collaboration Capabilities

Onshape enhances teamwork with simultaneous multi-user editing, where engineers can work concurrently on designs without file-sharing bottlenecks. The platform’s branching capabilities allow teams to explore multiple 3D printing design concepts independently while maintaining a single source of truth, dramatically accelerating the prototyping-to-production cycle.

…Accessibility That Matches 3D Printing's Flexibility

While 3D printing offers manufacturing flexibility, traditional CAD often imposes rigid hardware requirements and installation complexities. Onshape provides platform-independent access from virtually any device with a web browser, allowing engineers to modify designs from the shop floor while examining prototypes or make adjustments from client sites based on immediate feedback.

…Extensibility for Specialized Requirements

Onshape's FeatureScript capability allows engineers to create custom features that encapsulate specialized knowledge about 3D printing processes. Custom features become part of your standard modeling toolbar, allowing teams to codify 3D printing best practices and ensure consistent application across all designs.

For example, Inkbit, a Massachusetts-based additive manufacturing company, has published numerous custom features specifically designed for additive manufacturing, including hose barbs, luer locks, modeled threads, and dovetail O-ring grooves. These pre-built features become part of your Onshape design interface, allowing teams to implement 3D printing best practices consistently across all projects.

Accelerating Innovation Through Integrated Workflows

The combination of Onshape's cloud-native platform and additive manufacturing creates a powerful foundation for accelerated product development. According to McKinsey research from 2021, business leaders anticipate that approximately half of their companies' future revenue will come from products that don't yet exist today. This reality underscores the importance of development tools that support rapid ideation, testing, and refinement.

Onshape, combined with 3D printing’s rapid prototyping potential, enables engineering teams to evaluate multiple design concepts concurrently, gather feedback earlier in development cycles, identify problems before significant investment, and adapt quickly to changing requirements.

Tech Tip: Your Guide to Successful 3D Printing

Choosing the Right Software for Your 3D Printing Workflow

When evaluating 3D modeling or 3D CAD software for 3D printing applications, consider both immediate needs and long-term strategy. For many engineering teams, Onshape represents the optimal balance of technical capability, accessibility, and collaboration support.

As 3D printing continues evolving from prototyping technology to a mainstream manufacturing method, the limitations of traditional file-based software options become increasingly problematic. By selecting cloud-native Onshape for your 3D printing workflow, you position your team to leverage additive manufacturing's full potential, transforming your entire approach to product development in an increasingly competitive marketplace.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more