2:48

Design innovation just got smoother with Onshape’s ability to flatten surfaces. The “Flatten Surface” capability, introduced in release 1.190, empowers designers to transform complex 3D surfaces into precise, manufacturable flat patterns.

Drawing from industry-leading practices, Onshape’s Surface Flattening feature offers more than just a tool – it’s a new capability that prioritizes speed, accuracy, and collaboration.

Let’s start by better understanding the benefits of a tool like this by looking at some use cases.

Surface Flattening Use Cases

1. Turn 3D into Ready-to-Use Patterns with Precision

Onshape makes it easier than ever to convert designs into production-ready flat patterns. Whether you’re designing for flexible materials or rigid components, Flatten Surface ensures a flawless transition from 3D to 2D, eliminating guesswork and rework.

2. Accelerate Design-to-Manufacturing Timelines

In industries where speed is everything, Onshape helps you reduce iteration times. Generate flat patterns to get your designs into production/prototyping, faster, without sacrificing accuracy.

3. Enhance Flexibility with the Ability to Rip Edges

Quickly select “rip edges” to reduce distortion. Add seams or notches in the flattened pattern to enhance manufacturing accuracy. From industrial fabrics to metal parts, this feature ensures every pattern is tailored for optimal assembly and fit.

4. Reduce Waste and Optimize Material Use

By delivering highly accurate flat patterns, Onshape minimizes material waste in manufacturing. Create patterns that maximize yield and reduce scrap, supporting sustainable production practices across industries.

Industries That Benefit Most from Surface Flattening

Surface Flattening has potential across a variety of industries, particularly where intricate, flexible designs and manufacturability are key:

- Automotive and Marine: Simplify upholstery patterns, interior panels, or fabric overlays for vehicles and vessels to ensure improved fit and finish.

- Industrial Equipment and Packaging: Produce precise templates for covers, cases, and industrial materials that require tailored flat patterns.

- Composite Manufacturing: Flatten complex composite structures to ensure precise layering and material use.

- Furniture/Upholstery/Textiles: Quickly design and flatten patterns saving time and boosting precision.

Flatten Surface helps bridge the gap between complex design and streamlined manufacturing, enabling you to meet the demands of modern industries.

Experience the Future of Design-to-Production

Start flattening your designs using the steps below and see how it can improve your workflow.

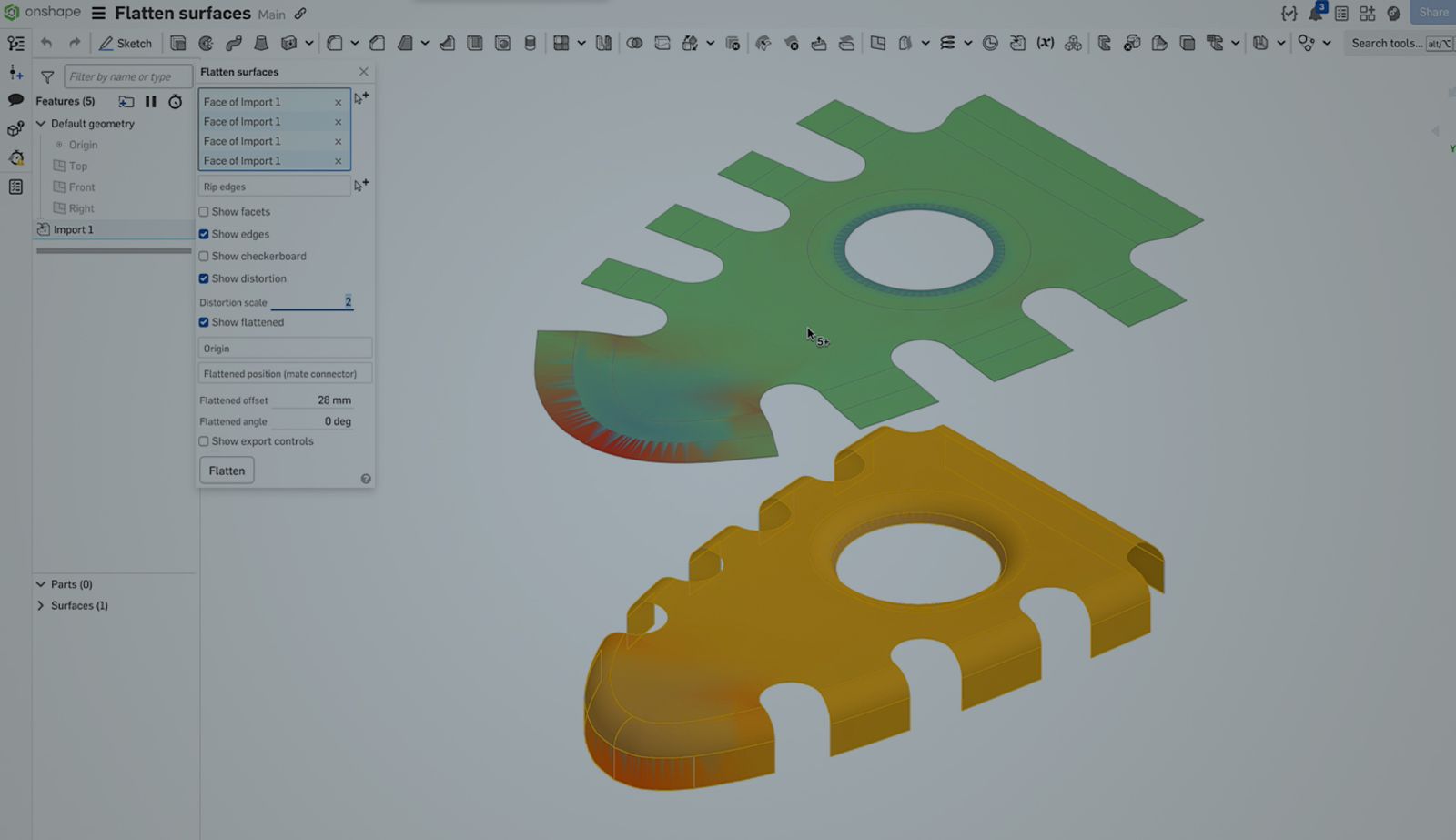

- Click the Show analysis tools icon () in the bottom-right corner of the graphics area. From the menu, select Flatten surfaces to open the dialog

- With the Faces to Flatten field selected, Select one or more contiguous faces in the graphics area. (Optional: Select the Rip edges field in the dialog, then select the corresponding edges where the surface should be ripped.)

- Analyze the flattened surface using a number of options:

- Show facets: Check to display the mesh facets on both the original and flattened surfaces.

- Show checkerboard: Check to display a black and white checkerboard pattern overlaid on both the original and flattened surfaces.

- Show distortion: Displays areas of the flattened surface where there is geometrical distortion as a result of the flattening process in magenta. The stronger the color, the more that distortion occurs.

Thats it! When you’re satisfied with the results, export to either PARASOLID, STL, DXF, or SVG, then its time to cut.

To see this in action, check out Greg Brown’s demonstration:

See For Yourself What Sets Onshape Apart

Borrowing from the best practices in advanced flattening solutions, Onshape’s Surface Flattening delivers the speed, precision, and collaboration your business needs to stay ahead.

Try Onshape Today

Head to our sign-up page to choose the right CAD plan for you and your team.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more