05:15

TL;DR: Michigan-based Alternative Engineering Inc. doubled revenue for 3 years straight after switching from traditional CAD to cloud-native Onshape. The custom machinery manufacturer cut project delivery from 18-20 weeks to 4-5 weeks, saved $1.25 million annually, and went 100 percent paperless. The company transformed from a small custom shop to a scalable products company by eliminating IT overhead and enabling live design changes during customer calls – proving that sticking with traditional systems poses the real risk to growth.

When manufacturing companies struggle with supply chain disruptions and talent shortages, Alternative Engineering Inc. (AE Inc.) has defied industry trends by doubling their revenue for three consecutive years.

The Michigan-based custom machinery manufacturer attributes this explosive growth to a strategic decision that many engineering leaders still debate: migrating from traditional desktop CAD to cloud-based design tools.

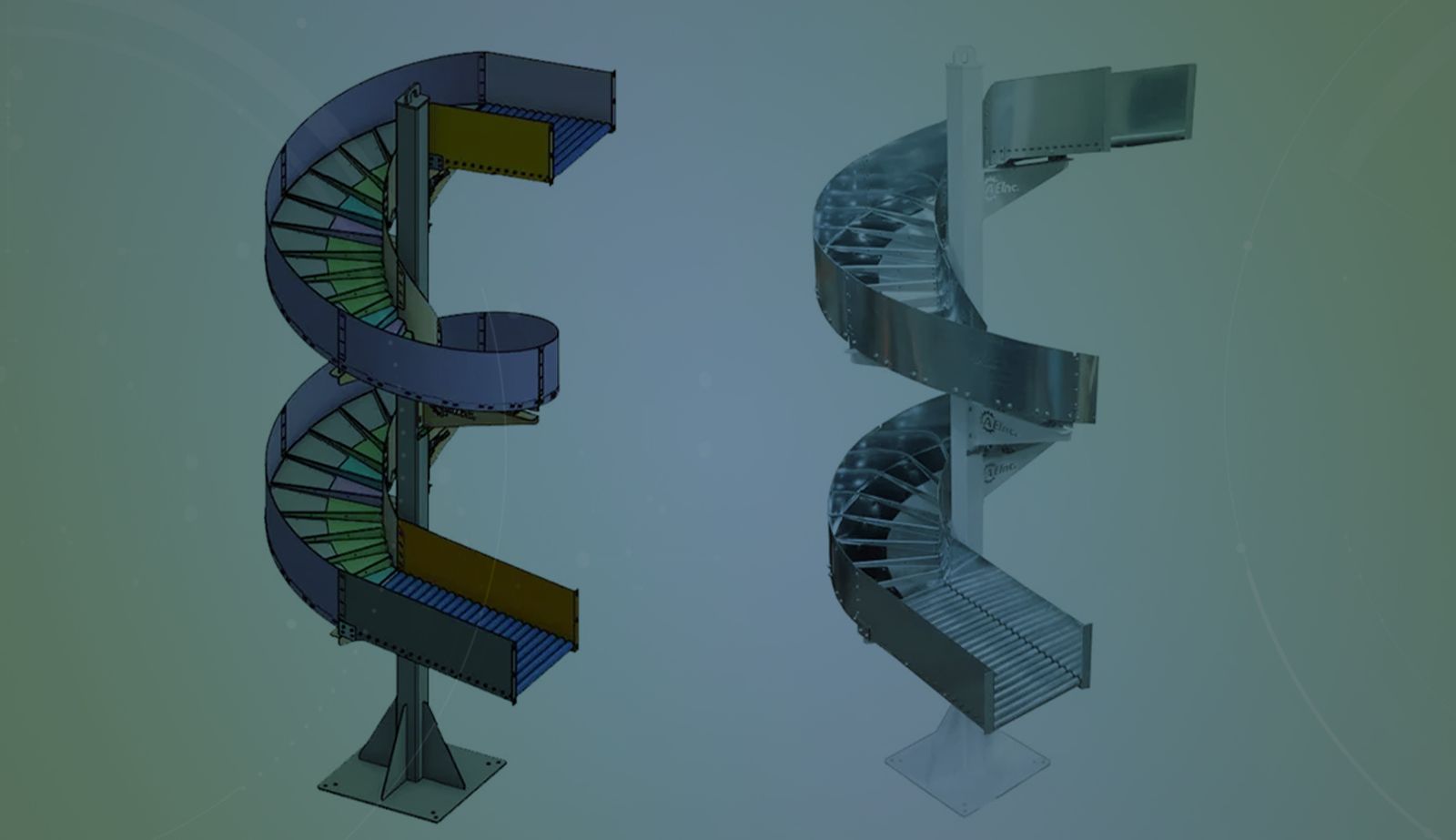

The company’s transformation story (which you can watch in full) offers compelling evidence for engineering executives evaluating their own digital infrastructure investments. After years of designing custom machinery using traditional CAD systems, AE Inc. made the leap to PTC’s cloud-native CAD and PDM platform – Onshape – a move that not only eliminated their IT overhead but generated annual savings through improved operational efficiency.

From Basement Startup to Industry Disruptor

Founded by Robert Rodriguez, who had a humble beginning as the son of Mexican immigrant farm workers, AE Inc. embodies the American entrepreneurial dream. Starting with a drafting board in his basement after leaving General Motors, Rodriguez built a company that now serves diverse industries with custom material handling equipment, automation systems, and conveyor solutions.

For two decades, the company remained small, with Rodriguez focusing on tackling the industry’s most challenging projects: the “ugly jobs” that larger businesses avoided. This approach built exceptional engineering capabilities but created scalability challenges that threatened long-term growth.

“I was driven by chasing the toughest projects,” Rodriguez said, “It’s really made us very, very agile. Very nimble.”

Breaking Away from Traditional CAD Limitations

Like many custom manufacturers, AE Inc. faced mounting operational friction from their SOLIDWORKS-based workflow. Rodriguez identified critical bottlenecks that resonated across the custom machinery sector.

The traditional CAD workflow required extensive IT infrastructure management, created version control nightmares across distributed teams, and demanded significant time for software updates and file management. For a company building thousands of unique machines, each essentially a prototype requiring extensive customization, these inefficiencies compounded exponentially.

“I call it building from a clean sheet of paper,” Rodriguez explained. “When you build a model, I have to be able to modify it. … This guy wants a left hand. He wants a right hand. He wants it longer, shorter.”

The Cloud Advantage: Real Numbers, Real Impact

The migration to cloud-based CAD delivered measurable business outcomes that CFOs and operations leaders notice immediately:

- Reduction in design-to-delivery time: Projects that previously required 18-20 weeks now complete in 4-5 weeks

- $1 million-plus annual savings: Eliminated IT overhead, reduced labor costs, and streamlined material ordering

- 100% paperless manufacturing workflow: Direct model-to-manufacturing reduces errors and accelerates production

- Infinite scalability: No hardware limitations when handling 6,000-plus part assemblies

Engineers can now demonstrate design modifications during customer calls, implementing changes live and securing approvals instantly, a capability that has become a competitive differentiator in winning new contracts. Live design changes for complex assemblies are enabled by Onshape FeatureScript, which allows user-generated features to live as first-class CAD citizens.

Strategic Lessons for Engineering Leadership

AE Inc.’s experience offers several strategic insights for engineering executives considering similar transitions:

1. Start with Business Outcomes, Not Features: The decision to migrate wasn’t about CAD features but about removing barriers to growth. The company identified that their traditional systems couldn’t support their vision of becoming a scalable, product-focused organization.

2. Leverage Existing Talent: Cloud platforms can democratize engineering capabilities. The elimination of complex IT requirements allows teams to focus on innovation rather than infrastructure.

3. Calculate Total Cost of Ownership: While subscription models may appear more expensive initially, AE Inc.’s analysis revealed dramatic savings when factoring in eliminated servers, IT support, software updates, and productivity gains.

4. Consider Competitive Advantage: In custom machinery, speed wins contracts. AE Inc.'s market differentiator is the ability to modify designs instantly, collaborate remotely, and deliver faster than competitors using traditional tools.

The Path Forward: Scaling Success

Two years after implementing their cloud-first strategy, AE Inc. has transformed from a project-based custom shop to a scalable products company. They’ve identified repeatable, high-value solutions that leverage their 30-year knowledge base while maintaining the agility to customize for specific client needs.

The company’s success challenges conventional wisdom about manufacturing technology adoption. While many firms delay cloud migration citing security concerns or change management challenges, AE Inc. demonstrates that the greater risk lies in maintaining status quo systems that constrain growth.

For engineering leaders evaluating their own digital transformation strategies, AE Inc.’s journey provides a compelling blueprint: Identify the operational barriers limiting growth, quantify the true cost of current systems, and recognize that modern cloud platforms have matured beyond early adoption risks to become competitive necessities.

As Rodriguez noted, “We’ve doubled our sales three years in a row. It’s crazy.”

Perhaps what’s truly crazy is the decision to continue letting traditional systems limit business potential.

Onshape for Enterprises

Move fast. Stay aligned. Design better with cloud-native product development.

Latest Content

- Case Study

- Aviation, Aerospace & Defense

Dufour Aerospace Accelerates Critical Cargo Drone Delivery with PTC’s Onshape and Arena

02.11.2026 learn more

- Blog

- Evaluating Onshape

- Collaboration

How Onshape Fixes the Broken Promise of Model-Based Definition

02.26.2026 learn more

- Blog

- Customers & Case Studies

- Automotive & Transportation

Powering Heavy-Duty Innovation: How Edison Motors Builds Next-Gen Hybrid Trucks with Onshape

02.26.2026 learn more

- Blog

- Evaluating Onshape

- Education

- Education & Universities

Future-Proof Engineering Education with Model-Based Definition in Onshape

02.24.2026 learn more