05:30

If your team designs consumer products or manufactures precision hardware, you already know that surfacing isn’t just for styling – it’s the foundation of how form meets function. Whether you’re modeling an ergonomic enclosure, defining draft angles for tooling, or validating cosmetic transitions, your CAD system’s surfacing tools can make or break the product development cycle.

And if you're still using a file-based CAD system, chances are you’ve run into one of the usual headaches: broken references, disconnected geometry, clunky imports, and version chaos. Onshape changes the game – especially when it comes to advanced surfacing workflows.

In this post, we’ll explore how Onshape delivers a modern, multi-part, collaborative approach to surface modeling. We’ll cover native geometry creation, the top-down “master model” technique, precision-driven design control, and built-in diagnostic tools for manufacturability – all without the pain of file-based tools.

The Surface Modeling Problem in File-Based CAD

Let’s be honest: traditional file-based surfacing workflows are brittle. You’re often working in isolation, referencing static geometry across disconnected files, hoping your references don’t break when upstream parts change.

Want to drive geometry from a common surface master? You better maintain strict naming conventions, manually sync files, and cross your fingers that the next PDM check-in doesn’t undo hours of work.

Surface modeling in legacy CAD tools is powerful, but it’s fragile – especially when teams need to collaborate or iterate quickly.

Onshape’s Answer: Multi-Part Part Studios

In Onshape, the foundation for powerful surface workflows is the multi-part Part Studio. Unlike traditional tools where every part exists in a separate file, Onshape lets you model multiple parts – and their shared surfaces – together in a single, unified environment.

This means:

- No more external references or broken links

- Full visibility and control over surface transitions between parts

- A master surface that naturally drives all related geometry

Whether you’re building a cosmetic enclosure, splitting tooling bodies, or working across shell and core components, multi-part Part Studios act as the “glue” that holds the design intent together.

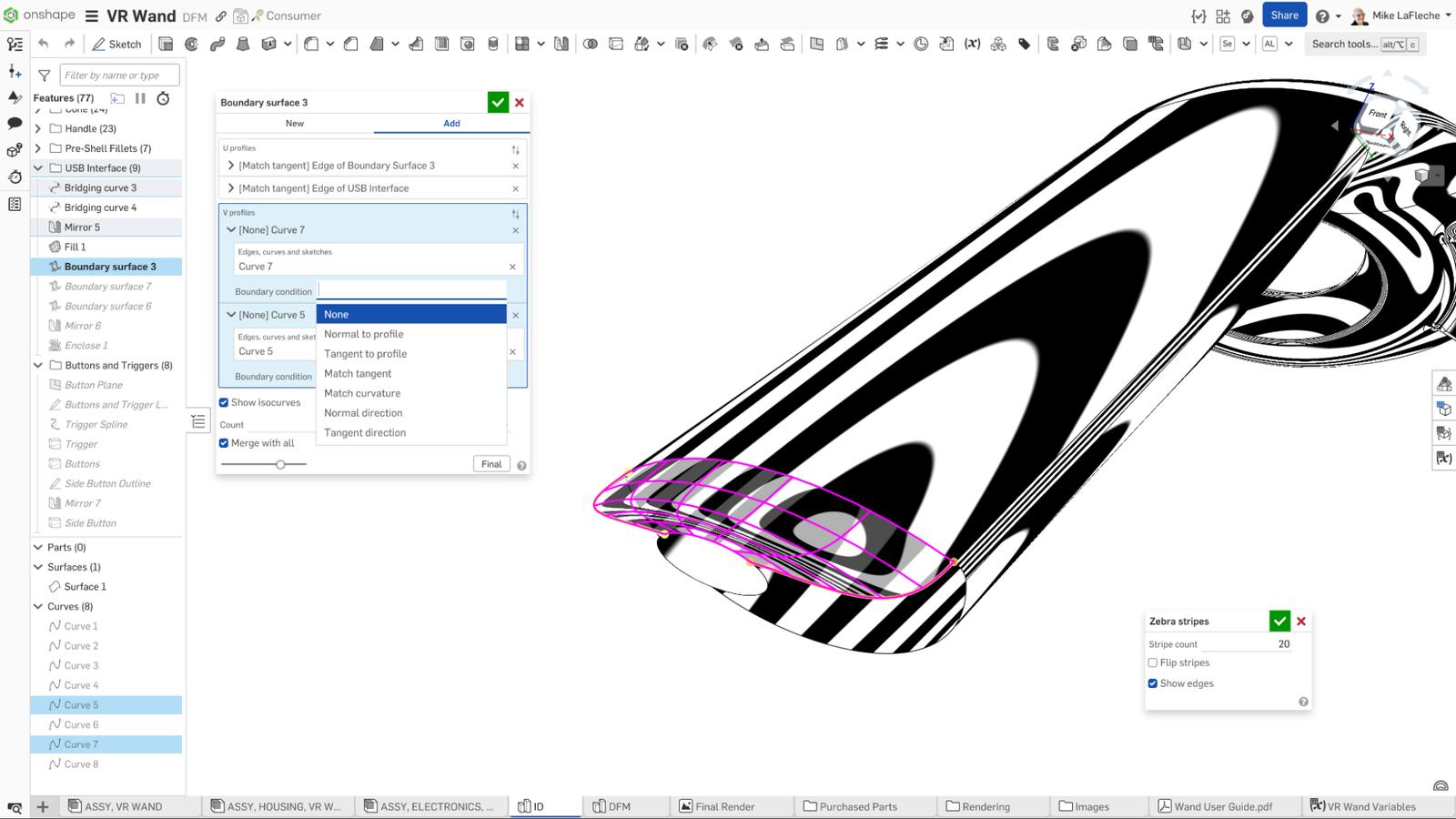

Native Surfacing Tools: Clean, Configurable, and Continuity-Driven

Onshape includes all the core tools you’d expect from a high-end surfacing environment:

- Lofted and Swept Surfaces with support for G0, G1, and G2 continuity

- Fill Surface for patching closed boundaries with curvature control

- Offset and Extend Surfaces for wall development or sealing gaps

- Enclose and Thicken to transform surface bodies into solids

Everything is fully parametric and version-controlled. You can define control curves, boundary conditions, and continuity right from the start – and easily revisit those decisions at any time without unraveling the model.

And with configurations, you can drive surface variation across product families or size ranges without duplicating your work. You’re working smart, not duplicating models.

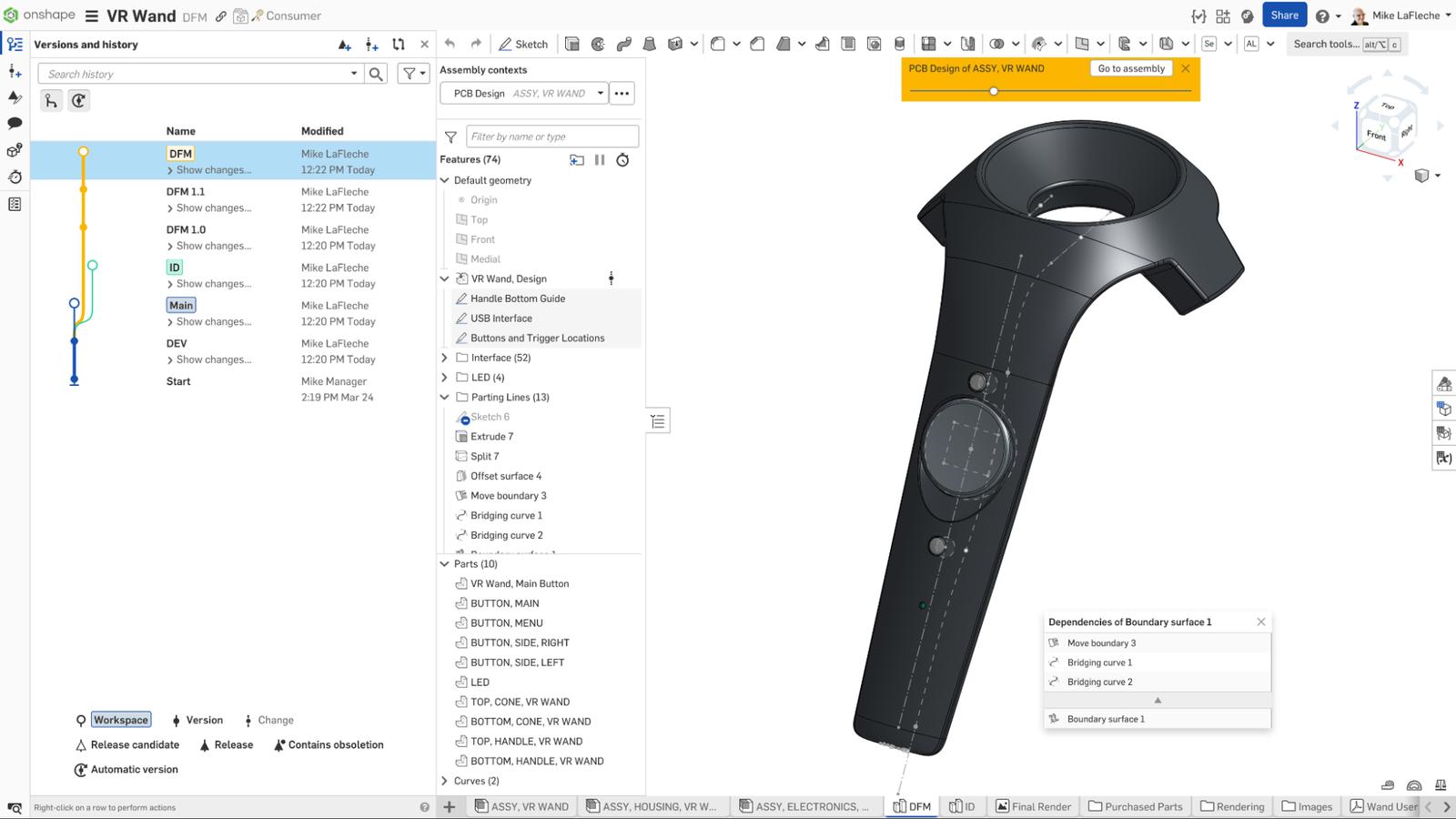

Top-Down Design and the Master Model Technique

Surface-driven workflows often start with a master model – a parent geometry that drives multiple child parts. Onshape makes this simple and robust with two key features:

- Derived Parts: Insert master geometry directly into downstream Part Studios. No fragile links. No file references. Just clean, controlled propagation.

- In-Context Design: Build parts directly in the context of assemblies or parent parts without locking yourself into unpredictable relationships.

Because everything is backed by true version control, your downstream geometry doesn’t break when the master updates – you control when and how it evolves.

This makes the master model technique not just viable, but safe and scalable.

Precision Control: Intent-Driven, Not Freeform

Onshape’s surfacing tools are built for control. This isn’t a digital clay environment; it’s a precise modeling system for production geometry.

You can:

- Define explicit boundary conditions (position, tangent, curvature)

- Use 3D Fit Splines and projected curves to lock down key transitions

- Split, trim, and manage surfaces with clean boolean logic

- Replace or extend faces without losing intent

This is critical when building surfaces that must pass design review, mold validation, and manufacturing readiness in one pass.

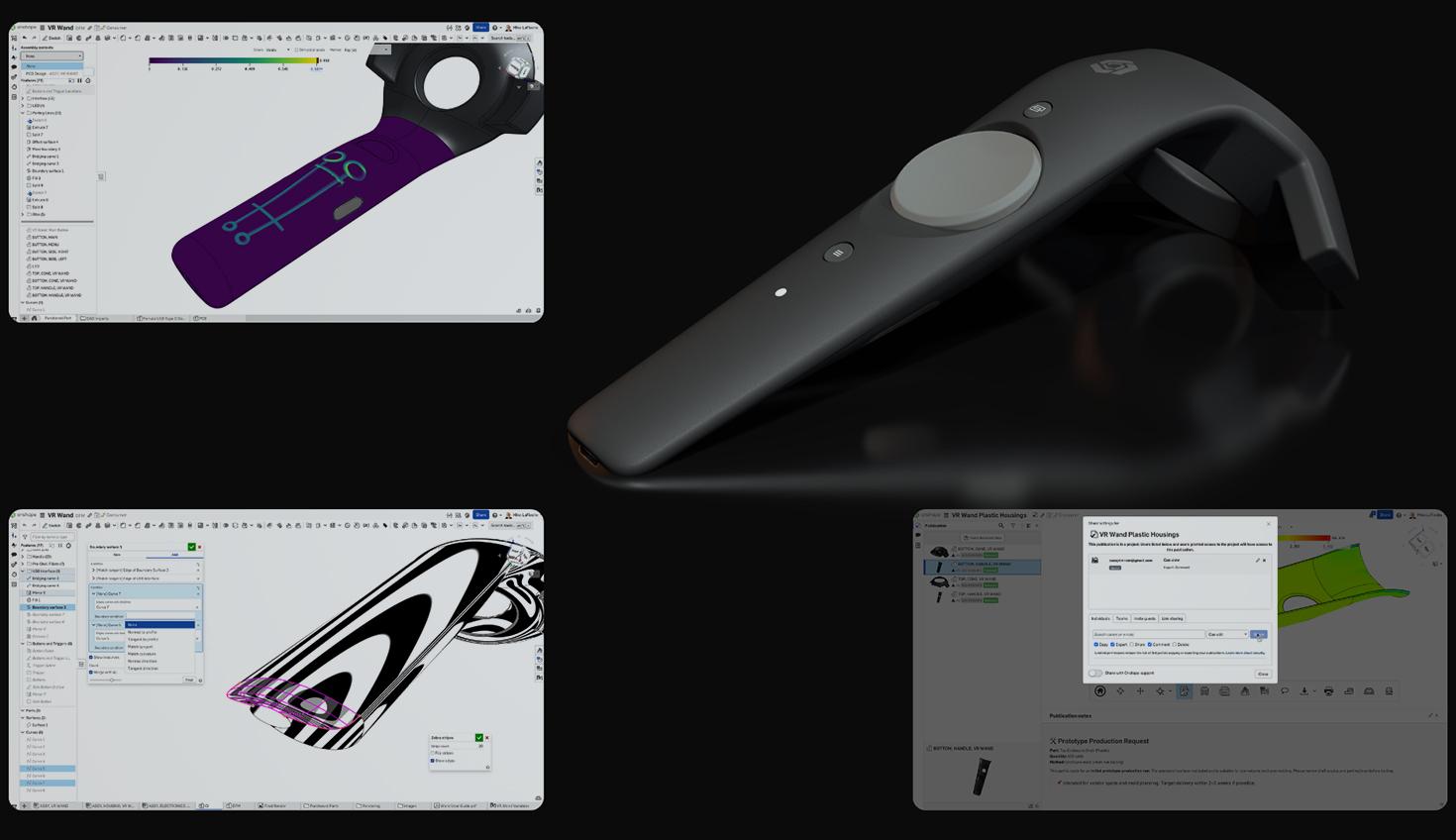

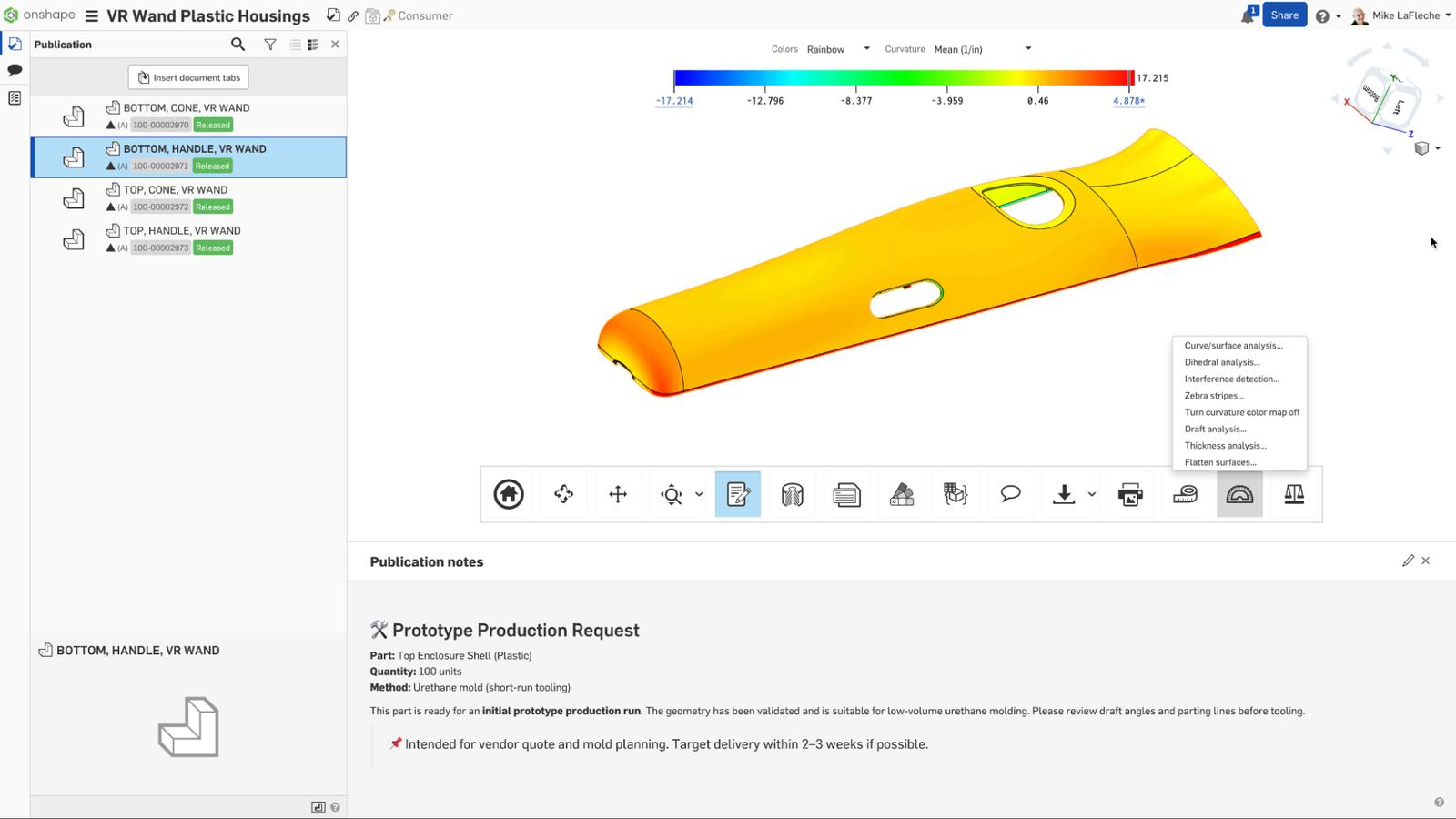

Built-In Diagnostic Tools for Class-A Surface Design and DFM

Designing advanced surfaces is only half the battle – you also need to validate them. Onshape provides built-in tools to help you analyze and improve your models without jumping into another app.

- Curvature Comb and Zebra Striping: Visualize surface flow and detect continuity issues

- Gaussian Curvature Maps: Highlight high/low regions and curvature inflection points

- Draft Analysis: Ensure pull direction and moldability from day one

- Thickness Analysis: Identify thin or overbuilt regions that affect tooling or strength

- Dihedral Angle Checks: Ensure proper angles between intersecting surfaces

These tools help you catch and resolve issues before they get to your manufacturer – saving time and budget.

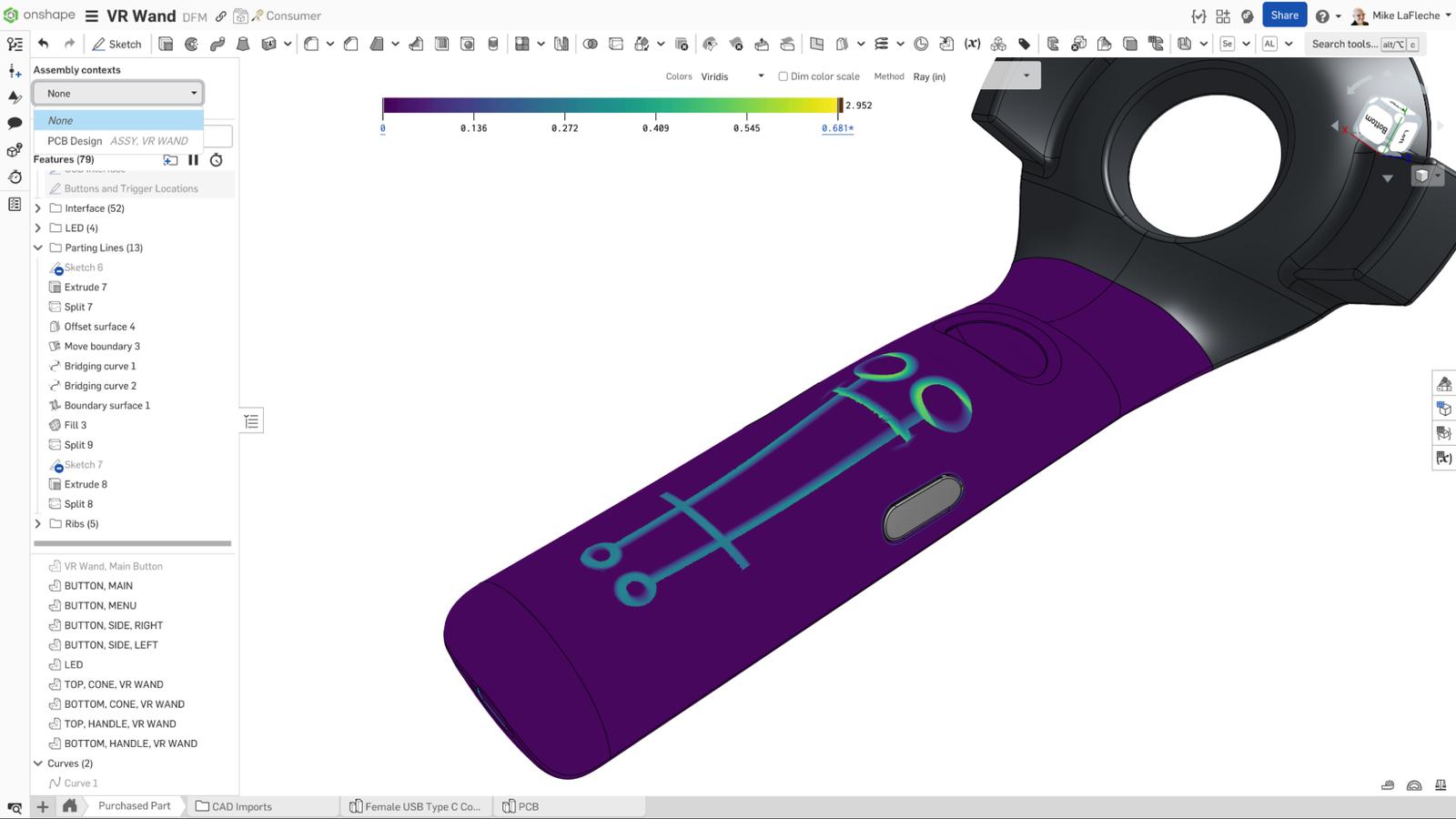

Real-Time Collaboration Across Design and Manufacturing

What really sets Onshape apart is how it supports collaboration across the entire product development process.

- Design firms can share master surfaces with OEMs using secure, version-controlled links.

- OEMs can comment directly on surfaces, assign tasks, and follow revisions live.

- Manufacturers can be brought in early – view-only if needed – to review draft angles, transitions, and wall thickness before the design is finalized.

No zip files. No email chains. No third party sharing platforms for extra money. Everyone’s working on or viewing the same geometry, in the same platform, with the access level you define.

Why This Matters: Surfacing Without Silos

If you’re evaluating whether Onshape is right for your team, and you work with surfacing-heavy consumer products or tooling-intensive workflows, here’s the bottom line:

Onshape brings surfacing out of the file silo and into the modern era.

Challenge | Challenge | Challenge |

Master Model Control | External references prone to breaking | Multi-part Part Studios with native control. |

Collaboration | Local files, exports, email chains | Secure, real-time cloud sharing |

Diagnostics | Often requires a full CAD application for full analysis | Built-in curvature, draft, thickness analysis, even for view-only collaborators |

Design Evolution | Manual file management, risky overwrites | Version-controlled branching and merging |

Challenge

Challenge

Challenge

Master Model Control

External references prone to breaking

Multi-part Part Studios with native control.

Collaboration

Local files, exports, email chains

Secure, real-time cloud sharing

Diagnostics

Often requires a full CAD application for full analysis

Built-in curvature, draft, thickness analysis, even for view-only collaborators

Design Evolution

Manual file management, risky overwrites

Version-controlled branching and merging

Reliable Surfacing Modeling Tools

Advanced surfacing isn’t just about modeling pretty shapes – it’s about building reliable geometry that serves the entire product lifecycle. Onshape empowers teams to do that in a flexible, robust, and collaborative way.

And with multi-part Part Studios at the heart of it all, you get a rock-solid foundation that’s purpose-built for modern design workflows.

If you're ready to break free from file-based fragility and build your next product in a truly modern CAD system, Onshape is ready for you.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more