04:05

Editor's Note: Onshape has been working with makerspaces across the U.S. to bring professional-grade CAD and PDM tools to makers on the shop floor. One notable collaboration is with PBS’s Make48 competition series, which takes place in various makerspaces nationwide.

In 2021, Hartford-based MakerspaceCT hosted a Make48 event and today, we're excited to share their story. Read on as MakerspaceCT Lead Instructor of Advance Technologies Erick Johnson takes us inside MakerspaceCT and their impactful use of Onshape in engineering programs.

Here at MakerspaceCT, we believe in enabling people to create anything they dream up using the best technologies available, including Onshape!

MakerspaceCT is a nonprofit makerspace in downtown Hartford, Connecticut, with the mission of positively impacting lives by enabling access, innovation, and education.

MakerspaceCT’s Educational Programs

One way we do this at MakerspaceCT is by offering 12-week education programs for young adults, the Engineering Fundamentals Course (EFC), and a similar program for high-school-aged students, the Engineering Primer Program (EPP).

In these courses, we teach the basic concepts of engineering through Design Thinking, CAD modeling, 3D printing, and electronics. Some of the projects that our students complete include lamps, Bluetooth speakers, and even a few robots!

Importance of Onshape

Learning CAD software with Onshape is the heart of these programs. We chose Onhape as the CAD software for EPP and EFC for several reasons. The first is that Onshape is browser-based, meaning it can be used on any device that connects to the internet.

Most of our students have a public school-issued Chromebook that doesn’t allow for most other CAD programs, but with Onshape, our students eagerly practice on their own time on any connected computer.

Secondly, Onshape’s robust Learning Center allows advanced students to learn at their own pace, while classroom instruction can slow down for those who need more guidance. Our students’ learning doesn’t stop when they get home – they spend time between classes learning from Onshape’s videos and tutorials in their Learning Paths.

Onshape’s sharing and collaboration tools have also enabled students to develop their own skills by helping their classmates. Especially when working on designing lamps, the students’ first independent CAD project, they ask for help with specific ideas. A sense of camaraderie in the classroom gives students the confidence to ask one another how they did something. With Onshape’s sharing ability, they can simply send the file to work on things together.

Finally, many of our students join our program because we offer it free of charge and these young people have limited resources and are hoping to better position themselves for better jobs. Onshape’s free account offering means the world to these students when they realize they will take the CAD tools they’ve learned in the program with them when they finish.

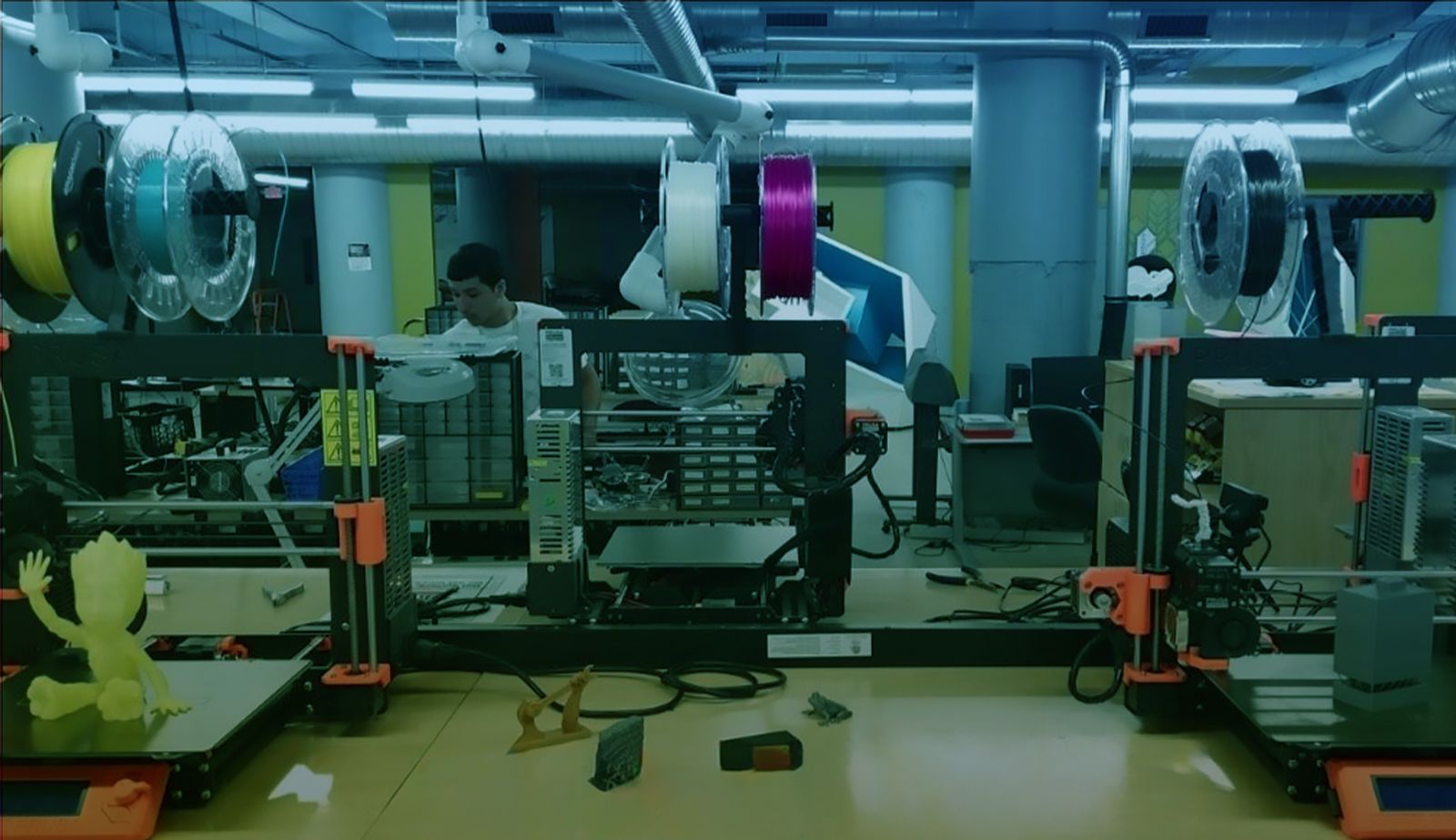

Teaching 3D Printing

3D printing is a specialty of MakerspaceCT and is a very important element for our EPP and EFC courses. For many students, operating in a 3D space on a 2D screen is not novel as almost all of them are video game enthusiasts. Students see the magic when they prepare that design and 3D print it. In an hour or two, they can hold it in their hand, in the real world. That's the moment when they realize the potential of these powerful tools and you can see it on their face.

Beyond the magic, 3D printing is most useful in the design process when students create a feature of their design that must fit the electronics provided to them. They take precise measurements using calipers and design accordingly. Onshape then allows them to section out that one feature, with a simple rectangle sketch and extrude: intersect. This creates a small test print of that feature that can be printed in a few minutes and the fit can be tested with the actual electronic part. By making small test prints, we can avoid wasteful and time-consuming large, whole-part prints. The combination of rapid prototyping and Onshape’s parametric editing makes for a fierce design tool set.

Cherokee's story: Post-graduation continuing education opportunity through the Primer Program.

Success Stories and Future Plans

We have been running the Engineering Fundamentals Course for two years now, and have been excited to see many students return to tell us about their new jobs in manufacturing! All of them have said that their CAD modeling experience at MakerspaceCT helped them get their new jobs. They could show off a physical object that they designed from nothing, and talk through their process, impressing all of the employers.

MakerspaceCT and the students here look forward to continuing learning with Onshape, as we advance and explore more tools!

Try Onshape Today

Head to our sign-up page to choose the right CAD plan for you and your team.

(Erik Johnson is the Lead Instructor of Advanced Technologies at MakerspaceCT.)

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more

- Blog

- Customers & Case Studies

- Collaboration

- Consumer Products

RigStrips Boosts Design Speed Using Onshape's Collaborative Tools

02.11.2026 learn more

- Blog

- Becoming an Expert

- Features

- Data Management

How Onshape's Repair Tool Fixes Broken References

01.29.2026 learn more