The Challenge

Based in Toulouse, France, Aura Aero is an aerospace company developing zero-emissions electric aircraft for regional passenger travel, military and civilian flight training, aerial acrobatics, and recreational pilots. Carbon emission reduction is one of its core missions. The company’s two-seat INTEGRAL aircraft will be released in 2024. Its 19-seat Electric Regional Aircraft (ERA) is expected to go into production in 2026. A year after Aura Aero was founded in 2018, the product development team was seeking a cloud-native CAD system to improve efficiency between its design office and the factory floor.

Results

- Onshape’s custom CAD features save the Aura Aero team 80 percent of their design time on repetitive tasks versus completing them manually.

- Onshape enables aircraft assembly workers to instantly access the latest designs on the factory floor, eliminating their reliance on paper manufacturing drawings.

- Onshape’s Branching and Merging feature enables engineers to explore new ideas in alternate branches without altering the main design. This feature encourages the product development team to take more creative risks.

- Accessible from anywhere and on any computer or mobile device, Onshape enables Aura Aero to easily share live 3D CAD models during visits with partners and vendors.

As our team grows, Onshape will be essential in our production because everyone’s work is visible to other departments in real time. There’s no waiting for design updates. Everyone can keep working without delays.’’

Whether it’s for business or vacation travel, airlines lure passengers with a variety of incentives like special fares, frequent flier miles or more leg room. But what if an airline promised you cleaner skies?

In Europe, that’s not just wistful environmental thinking. The European Union’s Climate Law sets a goal for member countries to achieve a 55% reduction in greenhouse gas emissions by 2035 (compared to 1990 levels) and reach full climate neutrality by 2050.

Addressing airline pollution, the European aviation industry recently stepped up to form the Alliance for Zero Emission Aviation (AZEA), a venue for business leaders to focus on the airport infrastructure requirements of electric and hydrogen aircraft. One of the members of AZEA’s Steering Committee is Aura Aero, a French aerospace company developing zero-emissions electric aircraft for regional passenger travel, military and civilian flight training, aerial acrobatics, and recreational pilots. Founded in 2018 by former Airbus engineers, the company’s mission is to “serve mankind by designing and manufacturing aircraft that accelerate air transport decarbonization.”

Aura Aero’s two-seat INTEGRAL aircraft will be released in 2024. Equipped with a whole aircraft parachute and an anti-deflagration fuel tank, the INTEGRAL planes are made from a blend of wood and carbon fiber to optimize lightness, resistance and reparability.

“Using wood is a tribute to aviation tradition and history, but it’s also part of our commitment to use renewable resources whenever possible,” says mechanical engineer Misael Hernandez Perez. “We are trying to do everything we can to minimize our impact on the environment. That drives every single design decision that we make.”

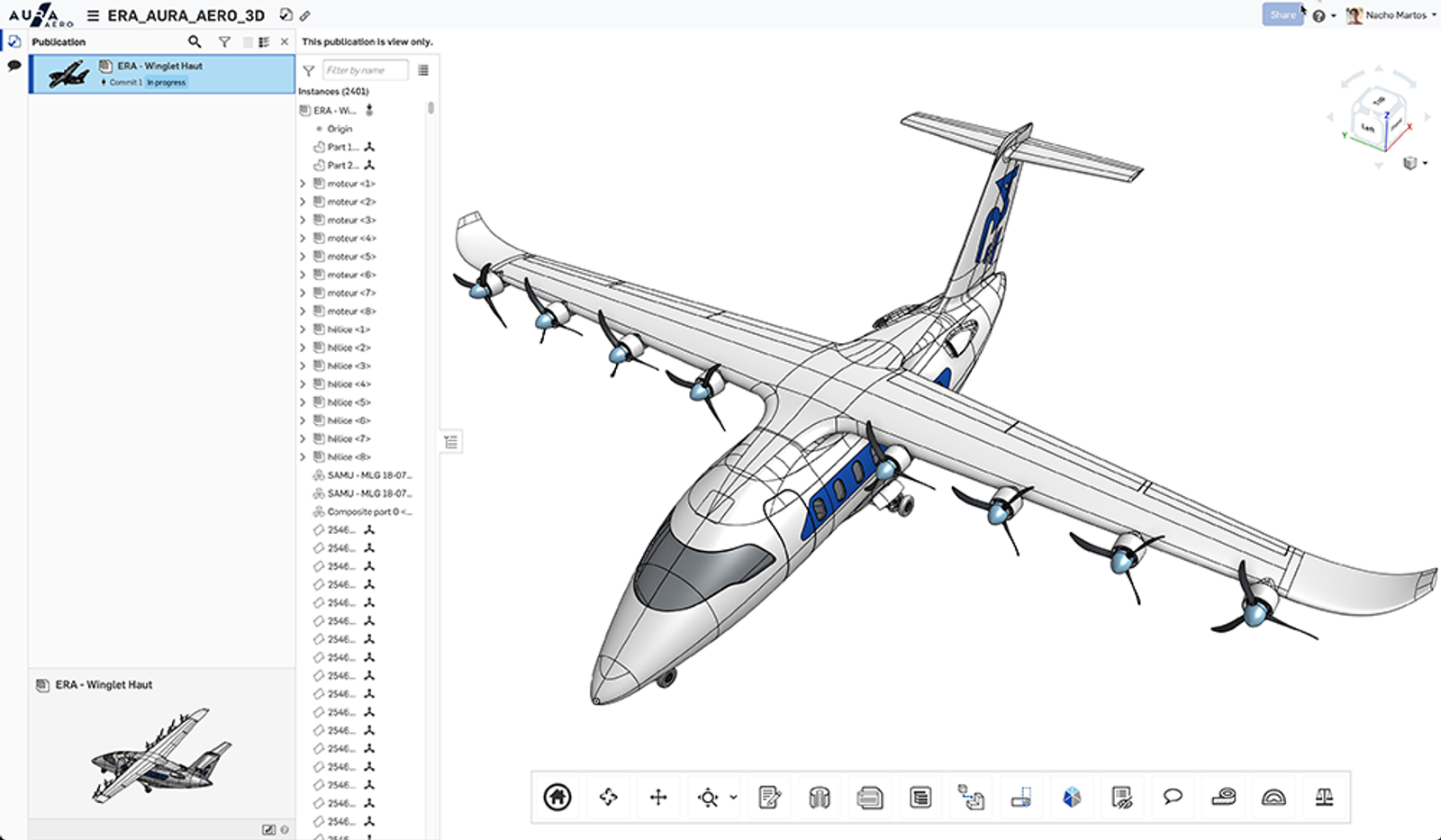

Aura Aero’s 19-seat Electric Regional Aircraft (ERA) is expected to go into production in 2026. The ERA plane, ideal for passenger travel or cargo delivery, has more than 500 pre-orders. It’s meant for shorter flights up to 300 miles, which have been previously out-of-range for electric aircraft because of the heavy battery weight. CEO Jeremy Caussade has declared that “Aura Aero could become the aeronautical Tesla.”

Pursuing a Cloud-First Company Strategy

To build their INTEGRAL and ERA aircraft, Aura Aero relies on Onshape, a cloud-native CAD and product data management (PDM) platform that streamlines collaboration and accelerates the design process.

When Aura Aero was choosing a product design software, it gravitated towards a full-cloud solution to align with the company’s goal to have all of its critical business data available anywhere from any device. Onshape runs in a browser on any computer, tablet or phone (iOS or Android), requiring no downloads or installs.

Alban Semond, Physical Design Manager at Aura Aero, was the company’s first engineering hire. Having used file-based product design software at previous companies, he recalls dealing with the hassle of frequent CAD system crashes.

“Many times with our previous CAD system, you might forget to save your design, the system would crash and you could lose a full day’s work,” he says. “It was extremely frustrating for the designer to start over. With Onshape, you never have a shutdown and you never have to save anything. Everything is backed up automatically.”

Looking back, Semond says the hardware and IT overhead savings provided by a Software-as- a-Service (SaaS) platform was also appealing to the budget-sensitive startup.

“With Onshape, we weren’t required to invest in expensive servers or heavy-loaded PC workstations just for running CAD,” he says. “With traditional CAD systems, hardware can be a big restraint. You’re dependent on the capacity of your PC, what kind of graphic card you have and how much memory you have.”

Improving CAD Collaboration and Streamlining Aircraft Assembly

The ability to access CAD data anytime, anywhere and from any device had an immediate impact on how Aura Aero conducted business.

“Onshape’s accessibility allowed us to save time and improve communication with suppliers and partners when sharing information,” says Semond. “We can visit any supplier and talk about any subject – whether it be commercial, technical, or strategy – and as soon as a question arises about a part, we can easily show the 3D model from our phones.”

Equally important is the ability for the core design team to share the latest CAD models companywide to sales, quality control, the environmental team, and manufacturing floor.

“Onshape has proved to be essential for our production line as it allows our assembly workers to have an overall look at the design, comprehend the design intent, or just know exactly where the part should be,” Semond says, noting that the process is far more efficient than relying on paper manufacturing drawings.

“Quality inspectors have the 3D model to reference their checks, and have easy access to the bill of materials and the versions of the parts that go in the assembly,” he adds. “Whenever there is a new release of a design, Onshape automatically sends out an alert to all the main players.”

Semond also credits Onshape’s Branching and Merging feature for further improving collaboration between Aura Aero’s engineers and designers. The feature enables users to explore new ideas in alternate branches without altering the main design, encouraging the team to take more creative risks without fear of losing their work.

“We can have two or more people working on different solutions to the same problem without mixing their workflows,” says Semond. “We can evaluate the branches and select the best solution, merging only what we want. We can even merge parts from more than one solution. At the same time, we can save the other solutions for possible future uses.”

Onshape’s Custom CAD Features Automate Repetitive Design Tasks

According to mechanical engineer Misael Hernandez Perez, one of Onshape’s most valuable benefits is FeatureScript, an open-source programming language that enables companies to create their own custom CAD features tailored to their industry.

Aura Aero created a special Onshape feature that automates the orientation of the wood grain in parts for the two-seat INTEGRAL aircraft. How the wooden parts are cut and how they are positioned impacts the strength of the shell and frame, according to stress analysis results. The feature allows carpenters and assembly workers to focus on their tasks versus worrying about how each part will fit and checking it manually.

“This feature saves us 80 percent of our time on repetitive tasks versus doing it the old way,” says Hernandez Perez. “It just speeds up everything. We no longer have to create an engraving on each part or recheck the entire process.”

The mechanical engineer says his team experiences similar time savings on repetitive tasks by using Onshape’s standard features like Replicate, which enables the placement of hundreds of bolts, nuts and washers with a few clicks versus adding them to the assembly one at a time.

Soaring Ahead With Onshape

Based at Toulouse-Francazal Airport, on the site of the French Air Force’s first aircraft hangar, Aura Aero’s headquarters includes its design office, manufacturing workshops, assembly lines and testing facilities all in one place. Toulouse is Europe’s aerospace capital, offering a critical ecosystem of manufacturers and suppliers servicing the aviation industry.

Aura Aero is now building a new factory onsite to meet the demand for its ERA aircraft.

As its product development needs expand, Semond expects that Onshape will continue to play a key role in the company’s success.

“As our team grows, Onshape will be essential in our production because everyone’s work is visible to other departments in real time,” he says. “There’s no waiting for design updates. Everyone can keep working without delays.”

Semond adds that Onshape’s quick learning curve is invaluable for onboarding new employees and getting them working on projects right away.

“The biggest thing for me is that we have designers fully integrated on the team after only three days of learning Onshape,” he says. “I remember at a previous job, our CAD system required a month or six weeks of training. Things move fast here. We can’t wait a month.”

“The online Onshape Learning Center is easy to understand with lots of self-taught tutorials,” Semond says. “The addition of tutorials in French was a big step forward for us.”