The Challenge

With a mission to make the world a better place through cycling, Trek Bikes is committed to building products they love, delivering outstanding customer service, and inspiring positive change. However, their outdated CAD system was hindering innovation. A reliance on aging servers and mismatched software versions across global offices led to system crashes, slow performance, and frequent data loss. Ensuring access to the latest files was a constant struggle, and their inefficient check-in/check-out process slowed down collaboration. These limitations were creating costly delays in product development.

To overcome these challenges, Trek sought a more flexible and collaborative cloud-native CAD and PDM platform. By adopting Onshape, they eliminated version control issues, gained real-time access to design data from any device, and streamlined collaboration across all locations—saving both time and cost.

Results

- Onshape enabled Trek engineers to accelerate the iteration process while maintaining a single source of truth.

- Trek reduced design time for bike frame cable routings from over a day to under 30 minutes with Custom Cable Routing FeatureScript.

- Onshape’s three-week release cycle delivers new CAD features regularly, keeping Trek engineers at the cutting edge.

- Real-time collaboration between Trek engineers and suppliers eliminated errors from outdated files, speeding up projects and reducing costs.

Onshape is the next version of CAD. Old CAD is very heavy, clunky, and archaic. And when I think about the Onshape platform, it's the next iteration. It's lighter weight from a support perspective; there's less that we have to do to take care of it and manage it. The Onshape platform is the tool that we've chosen for those reasons.’’

Trek’s Mission

Founded in a small Wisconsin barn in 1976, Trek Bikes has grown into a global brand dedicated to promoting cycling as a solution to major social and environmental challenges. The company believes that increasing bike usage can help combat obesity, disease, pollution, and urban congestion. More bikes on the road mean fewer cars, leading to reduced emissions, cleaner air, and more space for parks and recreational areas.

As Barbara Pierner, PLM Director at Trek, explains, “From Trek's perspective, one of the biggest priorities that we have is to create a great customer experience while delivering a great product as quickly as possible to the market. We're about innovation, but we're also about hospitality and a great customer experience.”

By transitioning to Onshape, Trek ensured that their product development team had a cloud-native, always-updated single source of truth, empowering them to continue pushing the boundaries of innovation while staying true to their mission.

Cloud-Native Design

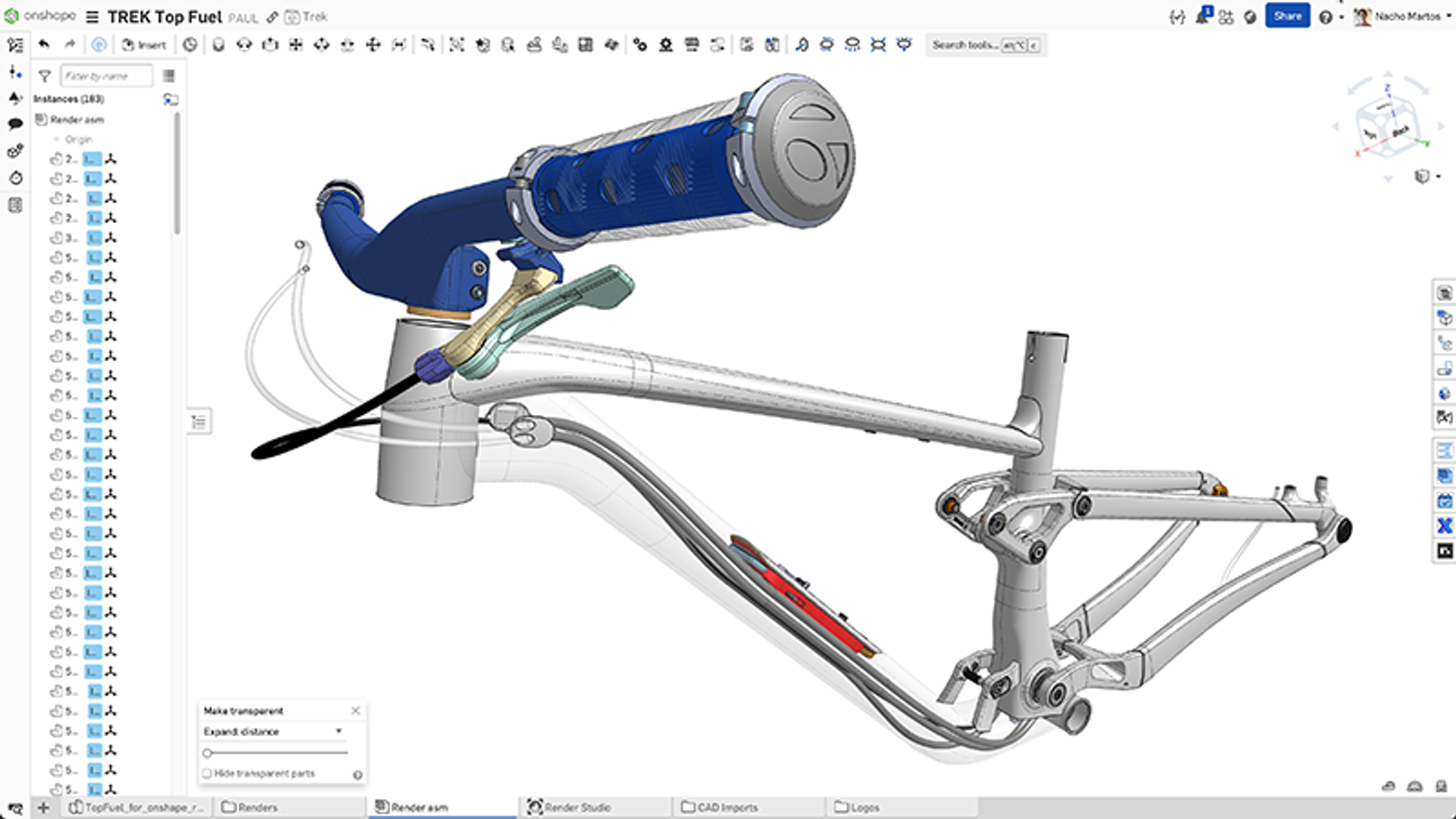

One of the main benefits of Onshape is its cloud-native architecture, which takes advantage of the cloud's full potential. When developing products, various people and systems have to work together – from engineers to suppliers, from CAD to PLM. This can result in a duplication of efforts and untracked copies of files.

Trek needed a solution where, starting with the CAD model, all of the information at the beginning feeds into multiple linked systems, seamlessly integrating the CAD system with every other touchpoint. With Onshape, data duplication is reduced. Everyone can collaborate on the same data simultaneously, creating a single source of truth. Furthermore, data is managed in the cloud, reducing the need for vast storage infrastructures and local IT. This capability went far beyond what SOLIDWORKS could offer.

“We are doing manufacturing and assembly reviews early in the process,” says Eric Gertner, Trek’s Chief Engineer “One of the things that's been most powerful for us with Onshape is knowing that we're all pointing at the same version of the model. It takes a lot of the questions out of the design process and lets us focus on the design itself rather than wondering if we have the right files.”

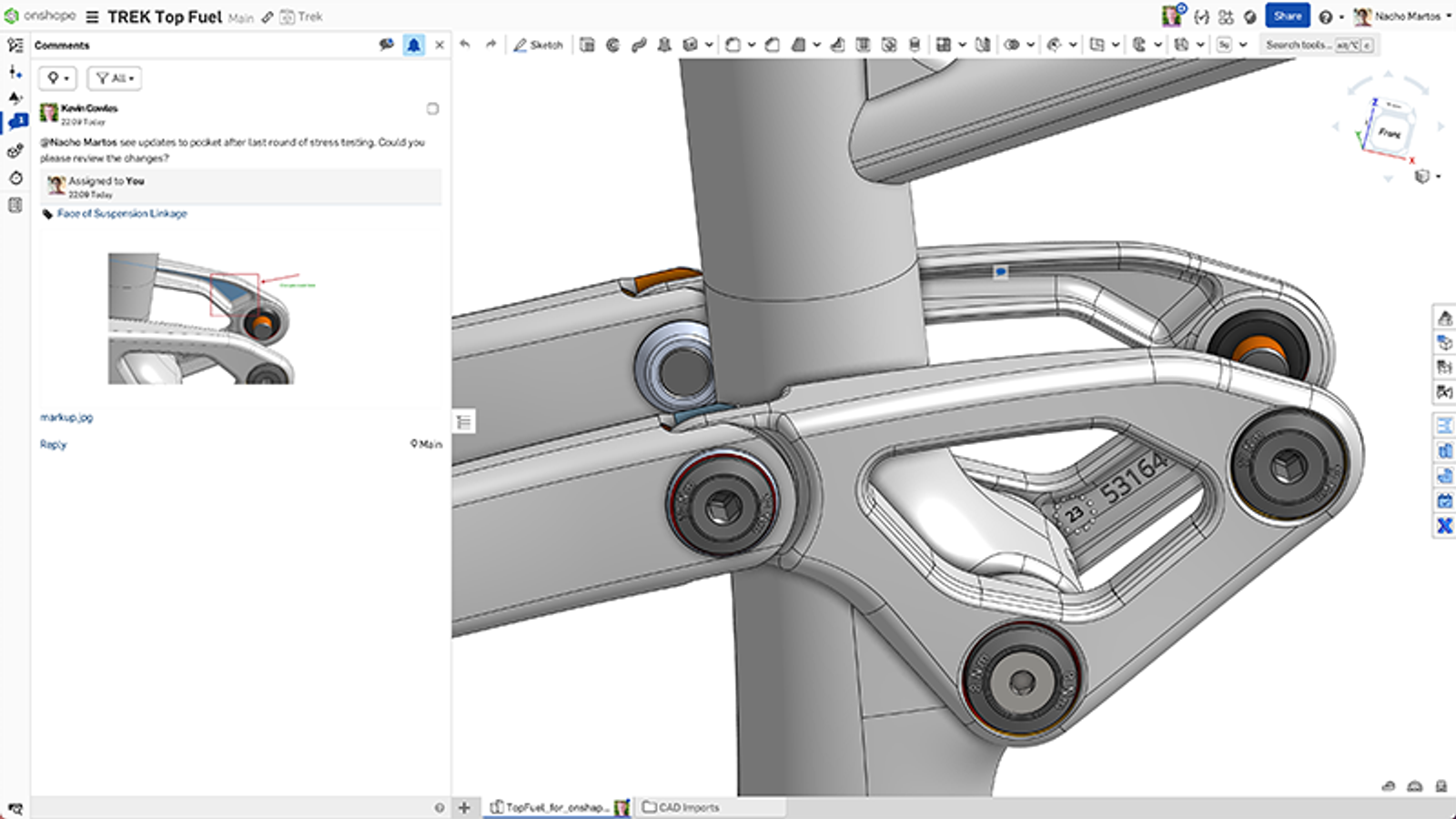

Design Collaboration

When Trek designs a helmet, global collaboration between multiple people across various locations is required. The process includes coordination between suppliers and engineers in Asia and industrial designers and engineers in the U.S., all while ensuring the highest level of consumer safety. The helmet must not only meet required industry standards but also undergo additional rigorous testing that exceeds those standards. This effort requires seamless teamwork, with individuals working in tandem across the globe to deliver a superior product.

“The biggest impact Onshape has had for us is just the speed at which we can collaborate. As long as we have some kind of internet connection, we can get to whatever it is we need to look at and make quick decisions,” says Nick Holzem, Advanced Surfacing CAD Designer at Trek.

A typical bike with 100 components requires even greater coordination. It is imperative to have access to the right files at all times. With Onshape’s built-in PDM, these concerns are eliminated. There is no need to check files in or out, and real-time collaboration capability ensures the correct version of the design is viewed by everyone around the world through the full development process, minimizing wasted time and delays. The team can be confident that the design and data are always current and accurate.

“Everything is moving to cloud collaboration,” says Brian Johnson, Engineering Manager at Trek. “Your Onshape models are always live. There’s no risk of sending an old file to a supplier. There's no risk of someone picking up an outdated model and working with it because everything you get in Onshape is live.”

Customizing CAD with FeatureScript

The ability to create custom features using Onshape’s FeatureScript has helped Trek with tire design, cable routing, and surfacing.

Trek created a custom feature that could help design complex tire treads and apply them directly to the tire in Onshape. They did not do this in SOLIDWORKS because it would have proven more difficult to manage the automation than maintain the inefficiency.

FeatureScript enables Trek to incorporate fully detailed tires into their CAD system for various purposes beyond just bike design. These digital tire models can be used to create virtual product representations for marketing materials or included in aerodynamic and traction studies, enhancing both promotional efforts and technical analysis.

“When I think about Onshape and, for example, all the things that you can do with the FeatureScript toolset, and all you can do with APIs and being able to integrate with the application,” Trek PLM Director Barbara Pierner says. “When I think about all the third-party apps that can be implemented on top of it, it just seems like it's almost boundless.”

FeatureScript was also used to ensure that cable routing is consistent across all their bike platforms.

“The Custom Cable Routing FeatureScript helps us route cables from the shift levers to the derailers to the front brakes and rear brakes,” Johnson explains. “A lot of it is routed internally to the frames, and it was very labor-intensive to do it with 3D splines, lofts, and sweeps in the past. Now, we can take our routing and create a path, saving us a lot of time.”

Trek sees the value of FeatureScript as not only saving time but also ensuring that all iterations of their product design are produced exactly the same, no matter which designer or engineer is working on the product. Without FeatureScript, accidents can happen. There is a good chance that everything is correct up to that 97th time when an unforeseen accident creeps into the design because someone missed something.

In the past, the CAD engineer had to account for brake cables, shift cables, wiring for e-systems, lighting, and more. Constructing this cabling required setting up many sketches and curve connections. They would also have to deal with an assembly with many parts and references, which could be tricky to manage and produce errors from broken or missing references. Using the Cable Routing FeatureScript in Onshape eliminated many of these issues. Now, all the engineer has to do is select the cable guides or Mate Connectors as a path for the cable routing, and the cable conforms to the proper path.

“We can do a full frame in less than a half hour,” says Rhett Robinson, CAD Engineer at Trek. “In previous systems, that took over a day. It’s a really big headache. This is my favorite FeatureScript in Onshape. It’s a huge time saver for us.”

Bridging curves is another Onshape feature that has made surfacing easier for Trek. In their previous software, creating surfaces required engineers to generate multiple planes, sketches, and projected curves, a time-consuming process that became cumbersome, especially during numerous design iterations. This often led to design complications or breakdowns. With Onshape, the Bridging Curves feature not only accelerates the workflow but also reduces the number of features needed in the feature tree. Additionally, it simplifies collaboration, making it easier for team members who are new to the project to jump in and work on the design.

According to Robinson, “Bridging curves is a super helpful tool that is unique to Onshape. They speed up the process of creating additional surfaces and save time. The model is more robust as changes are made to it during the design phase.”

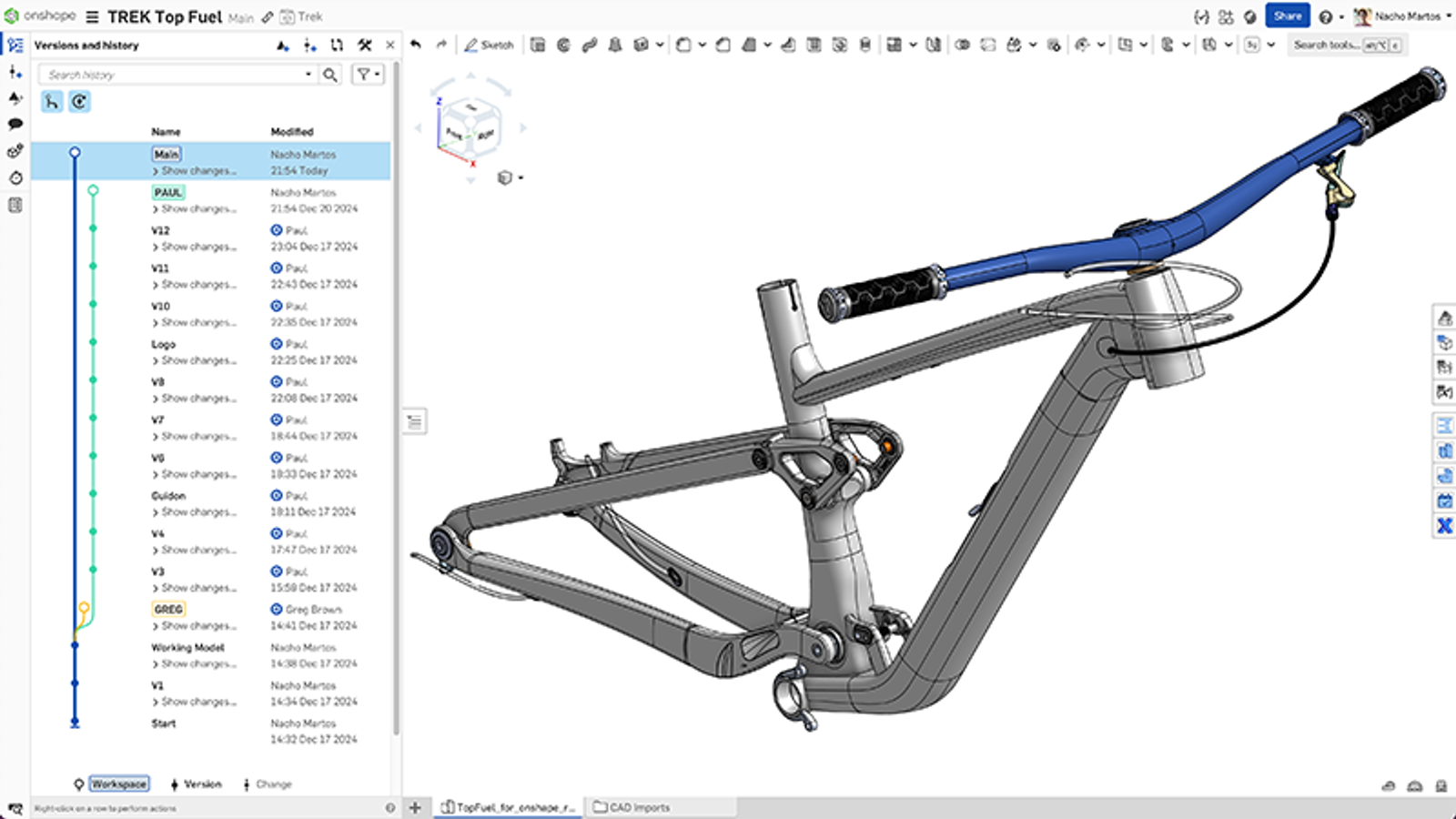

Branching, merging, versioning, and history tracking are also important tools that allow engineers to focus on what they do best: engineering. Instead of spending time focusing on how files should be organized, they can focus on innovating their designs. Branching allows them to explore different design ideas while merging allows them to selectively merge the best parts from the exploration into the main design within the same document. Additionally, the entire document history is accessible at any point for review.

“Because I know that anything I do can be undone, I can always go back. I can always go forward. I have all that history,” says Robinson. “It makes me want to do engineering. It makes me actually want to do my job. Rather than be annoyed and think I have to waste all this brainpower just organizing what I’m working on rather than focusing on what I’m working on.”

The Benefits of Agile Development

Onshape’s frequent release cycle ensures that the platform improves every three weeks, continuously enhancing the CAD experience. This regular influx of new functionality accelerates the design process, offering consistent upgrades far more frequently than the two-year software update cycle previously followed at Trek.

With Onshape, customers don't have to lift a finger. Every three weeks new features are added automatically and seamlessly, eliminating the need for customers to manage software upgrades or install them on multiple machines across different locations. Additionally, customers don’t need to worry about testing new releases. Onshape rigorously tests all improvements before they go live, ensuring a smooth and uninterrupted user experience.

The open communication between the Trek team and Onshape has led to several improvements on both sides. Implementing several suggestions by the Trek team has led to improvements in areas like surfacing and cable routing for all Onshape customers.

According to Chief Engineer Gertner, “Our relationship with Onshape has been very collaborative. It's something that I've not been used to in the past. Typically, the software you get is the software that you get, but with Onshape, we've been able to point to things that either need more focus or more work or some other features that we're requesting, and those get listened to, and we see those when they come out.”

A Future with Onshape

Trek’s future looks even brighter with its partnership with Onshape, positioning the company to create superior products and drive continued market growth. With hundreds of bike models and related products released annually, the production team remains focused on delivering the latest innovations across various categories, including road, mountain, city, and electric bikes for both kids and adults.

Trek anticipates that Onshape will continue to play a pivotal role in its success. In fact, Trek has committed to launching all model year 2026 production projects using Onshape from the start, solidifying the platform’s importance in Trek’s development process.

“Onshape's technical support is amazing,” says Holzem. “All my tickets get answered within less than six hours. They're that quick to help. All those people are great. Every piece of feedback I get is helpful in some sort of way. And if we don't get to it right away, there's a lot of back and forth, and they'll take it to the end. They won't leave an issue alone until you're satisfied. I would say the support is lightyears beyond what we had in the past.”

Onshape listens to their needs and brings new functionality, such as custom surfacing and routing features, to their design team. This results in engineers saving time by working smarter and faster, always confident that the latest documents are being used by everyone on the team in real time. This, in turn, translates to major cost savings across the organization.

According to Johnson, “Onshape provides us with quicker turnaround times on designs and iterations of designs, helping us get our products to the market faster.”