02:52

Fillets and Face Blends are both powerful tools in Onshape for creating smooth transitions between surfaces. Fillet is the preferred choice for most geometric rounding and constant-radius transitions, especially in prismatic or mechanical designs. Face Blend complements these capabilities by offering greater flexibility and control in complex surfacing scenarios.

Understanding Fillet Strengths

The Fillet feature is optimized for speed, reliability, and predictable modeling outcomes. It handles constant-radius and variable-radius blends, supports asymmetric filleting, and works well in most connected-solid workflows. For the majority of part modeling tasks, a fillet provides clean transitions with minimal setup.

Why Fillets Sometimes Fail

Fillet failures are usually caused by geometric conditions rather than limitations in the feature itself. Common root causes include:

- Highly curved or rapidly changing surface intersections

- Small faces or narrow edges that shrink during the fillet operation

- Multiple edges converging at a single point with incompatible curvature

- Downstream topology that prevents the fillet from trimming correctly

When the underlying geometry becomes too complex or produces conflicting curvature requirements, the fillet solver may not be able to generate a consistent rolling-ball surface.

Where Face Blend Helps

Face Blend is designed for situations where more control is needed than a rolling-ball or variable-radius fillet can provide. It allows blending between connected or disconnected surfaces, and can generate transitional surfaces that are independent from the parent faces. This makes it especially useful in industrial design, consumer products, freeform transitions, and sculpted geometry.

Key Capabilities of Face Blend

Face Blend provides options that go beyond traditional filleting:

- Multiple cross-section types, including rolling-ball and swept profiles

- Advanced propagation controls, such as tangent, adjacent, or custom

- Constraints and limits that manage start and end conditions

- Support for symmetry, trimming adjustments, and hold lines

- Ability to detach blends for later use in a surfacing workflow

These tools let you shape curvature flow and manage transitions with a higher degree of control.

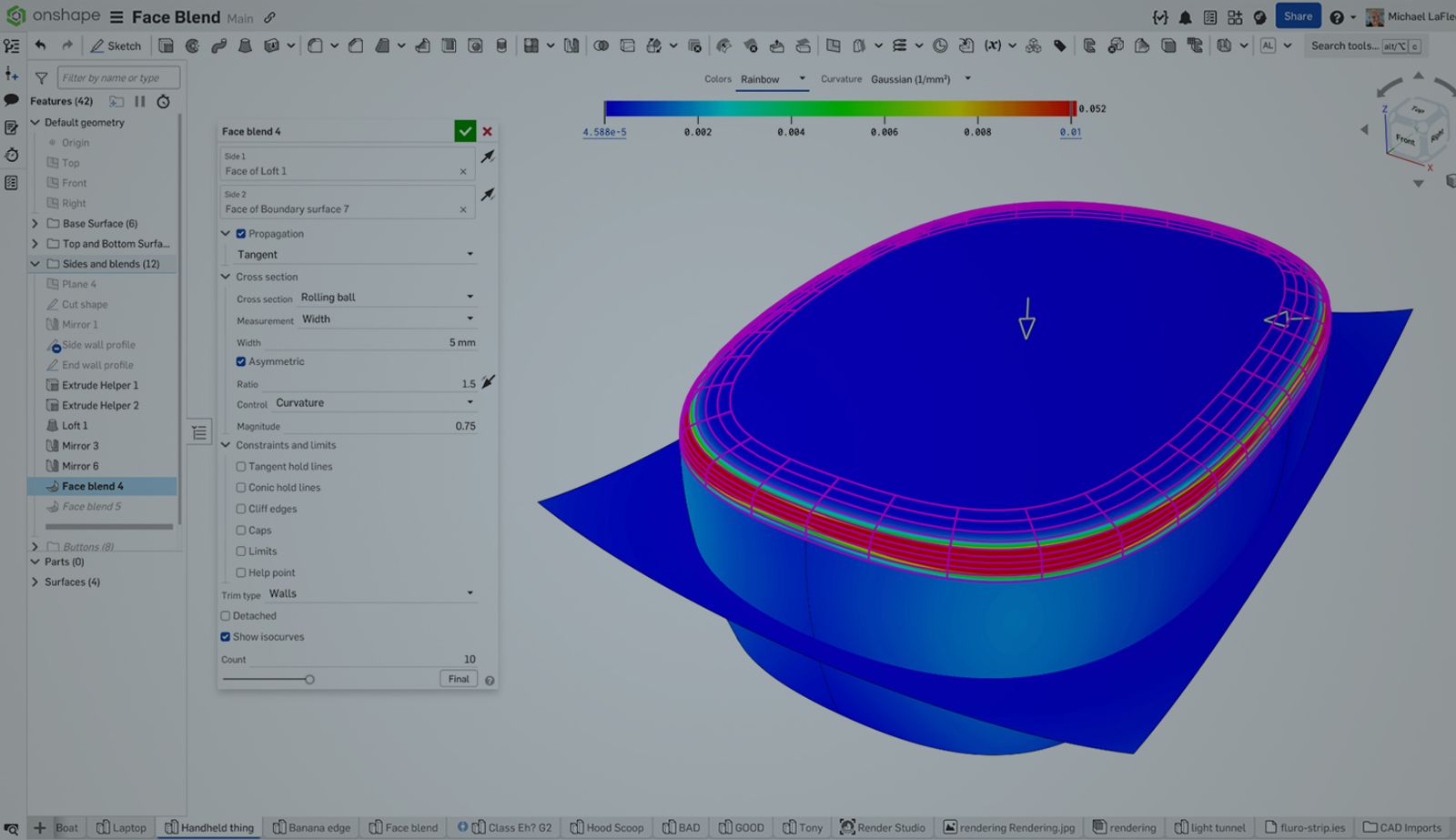

The many use cases of Face Blend in action:

Choosing the Right Tool

Use Fillet when the geometry is primarily mechanical, edges are well defined, and a constant or variable radius gives the intended result.

Use Face Blend when standard fillets cannot produce the curvature quality you need, when surfaces do not meet cleanly, or when you require a sculpted or direction-controlled blend that follows a custom profile.

Functionality | Fillet | Face Blend |

Works on connected faces | Yes | Yes |

Works on disconnected faces | No | Yes |

Creates independent (detached) surfaces | No | Yes |

Constant-radius transitions | Yes | Yes |

Variable / asymmetric radius options | Yes | Yes |

Curvature-continuous transitions (G2) | Yes | Yes (with full control) |

Complex curvature control (magnitude, hold lines, constraints) | Limited | Extensive |

Rolling-ball cross-section | Yes | Yes |

Swept-profile cross-section | No | Yes |

Advanced propagation options | Edge-based, standard propagation | Adjacent, tangent, custom, multi-surface propagation |

Control over trimming, limits, and start/stop conditions | Basic trimming and edge selection | Full trimming controls, explicit limits, directional controls |

Uses hold lines for guiding curvature | No | Yes (tangent, inverted tangent, custom) |

Handles multi-edge convergence well | Often challenging | Designed specifically for complex transitions |

Surface sculpting / freeform control | Limited | High |

Optimized for mechanical geometry | Yes | Yes, but primarily for surfacing workflows |

Preferred for industrial design curvature flows | Sometimes | Frequently |

Performance and simplicity for common transitions | Excellent | More setup required |

Functionality

Fillet

Face Blend

Works on connected faces

Yes

Yes

Works on disconnected faces

No

Yes

Creates independent (detached) surfaces

No

Yes

Constant-radius transitions

Yes

Yes

Variable / asymmetric radius options

Yes

Yes

Curvature-continuous transitions (G2)

Yes

Yes (with full control)

Complex curvature control (magnitude, hold lines, constraints)

Limited

Extensive

Rolling-ball cross-section

Yes

Yes

Swept-profile cross-section

No

Yes

Advanced propagation options

Edge-based, standard propagation

Adjacent, tangent, custom, multi-surface propagation

Control over trimming, limits, and start/stop conditions

Basic trimming and edge selection

Full trimming controls, explicit limits, directional controls

Uses hold lines for guiding curvature

No

Yes (tangent, inverted tangent, custom)

Handles multi-edge convergence well

Often challenging

Designed specifically for complex transitions

Surface sculpting / freeform control

Limited

High

Optimized for mechanical geometry

Yes

Yes, but primarily for surfacing workflows

Preferred for industrial design curvature flows

Sometimes

Frequently

Performance and simplicity for common transitions

Excellent

More setup required

Modeling Advice

If you encounter repeated fillet failures:

- Simplify the underlying surfaces before applying the fillet

- Add small transitional fillets earlier in the workflow

- Reduce the radius until the geometry supports the operation

- Consider changing the order of operations to avoid over-constraining the topology

- Switch to Face Blend when you need manual control of direction, curvature, or limits

Complementary Surfacing Tools

Fillet and Face Blend are complementary tools. Fillets are the backbone of most mechanical modeling tasks, while Face Blend gives you the extra surfacing precision needed for complex, aesthetic, or disconnected transitions. Understanding when to use each feature will help you model more efficiently and produce cleaner, higher-quality surface results in Onshape.

Friends Don’t Let Friends Use Old CAD!

Know a colleague who could benefit from our cloud-native, fully-featured collaborative design platform?

Latest Content

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more