09:20

When I designed my own engineering program in 2010, I knew CAD would be a foundational skill for my students as they dreamt up engineering projects and worked to turn their ideas into reality.

At the time, the most practical solution for my CAD needs was SolidWorks for Students, so I called up a local software reseller to obtain a set of student licenses. Then, despite my school’s tight budget, I convinced the IT department to buy me 30 powerful workstations with the requisite graphics cards so my students could start learning CAD.

The first lesson I developed to acquaint my students with the basics of CAD was a caster wheel assembly, which was composed of nine simple parts and a few standard nuts and bolts. For the next several years, this introductory assignment remained CAD lesson number one for new students in my engineering program.

During the summer of 2021, it became evident that the COVID pandemic was not going away, and my school would not be opening in person in the fall. This meant that my engineering students would not have access to any of the engineering tools in the building, including our computer lab.

The Switch to Onshape for Education

I started going through my engineering curriculum, scrambling to convert it into something that would work remotely. I ran an internet search for “online CAD” expecting to find nothing, but thankfully discovered Onshape, PTC’s cloud-native CAD and PDM platform.

READ: How to Know Which Onshape Education Plan Is Right For You

I was amazed by how clean and intuitive Onshape was and that professional-level engineering CAD could run smoothly in a web browser, even on one of my school’s old student Chromebooks. I knew that Onshape was the CAD solution I was looking for and I immediately set about rewriting my CAD curriculum.

During that first year using Onshape, I had two main revelations. First, Onshape is as capable as any other professional CAD platform out there, just easier to use. And second, if you are coming from an older CAD system like SolidWorks, there are a few surprising workflow improvements you should be aware of before you start your journey with Onshape. Below is a brief breakdown, to hopefully assist other educators in their transition to the future of CAD.

6 Reasons Onshape's Workflow Works Better for Students & Educators

Documents, Not Files

As mentioned earlier, Lesson 1 in my classroom was a nine-part caster assembly. Students would start by creating the nine parts, each saved as separate part files. Then, if they got all of their dimensions correct, they could build an assembly from the parts.

As an exercise to teach myself Onshape, I attempted to recreate the caster assembly. First, I created a new Onshape document and modeled the first part in the caster lesson. Then, I created a second Onshape document and modeled the second part. Once I had all nine parts modeled in nine Onshape documents, I created a 10th Onshape document, navigated to the assembly tab, and inserted the parts one at a time into the assembly.

I was pretty proud of my progress until a serendipitous internet search revealed that I had been going about my work all wrong! While resembling a traditional CAD platform on the surface, there are a few old workflows that Onshape throws out the window. Importantly, Onshape does away with files in favor of the much more powerful and versatile concept of documents.

An Onshape document is a container for the parts, assemblies, subassemblies, drawings, and other data pertaining to your design. The designers of Onshape probably would have fallen out of their chairs if they had seen me creating all of those separate documents. After some necessary unlearning, I rewrote my caster lesson. Now, students simply make one caster document. Within that document, they create all of the parts in a couple of Part Studios. Then, in the same document, they create their assembly and insert nuts and bolts. All in one document in the cloud.

Part Studios

Once I realized that all of my parts and assemblies could live in one document, the next revelation was the concept of Part Studios. In traditional CAD, each part is designed as its own file. For example, in the caster assignment, students create two base plates that will eventually be assembled together. Before Onshape, the students created the plate files separately, careful to duplicate the dimensions precisely, so they lined up during the assembly process.

Part Studios are design spaces that can contain as many parts as you want. If two parts, like the two plates, are going to share geometry, why not design them together? In a Part Studio, one sketch can be used to create multiple parts and parts can reference each other’s geometry. This is such a faster, more robust, and more intuitive way to design.

For my caster assignment, students designed both plates in one Part Studio with only a few features. In another Part Studio, they designed the wheel, tire, axle, axle bearings, and retaining collars all together. An assignment that used to take a week was now taking students only a day, thanks to the efficiency of Part Studios.

Assemblies and Mate Connectors

In a traditional CAD platform, assembling the two base plates would typically require three mates, each successively constraining the degrees of freedom of the parts. For example, a student might mate the two plates to be flush, then mate two of the bolt holes to be concentric. With those two mates, the parts could still rotate about that constrained bolt hole. A final third mate would lock the two parts together.

If CAD had an awards show, I think Mate Connectors would win Best Picture. With Mate Connectors, assembling two parts together almost never requires more than two clicks. Mate Connectors are three-axis coordinate systems that implicitly lie at every practical location in your parts’ geometry. And in the rare instance that a Mate Connector does not exist where you want it, they can be created explicitly.

In order to define the mechanical relationship between any two parts, simply select two Mate Connectors and specify how you want them to be related. A Fastened mate will lock the two Mate Connectors together, as with the two base plates. Use the Revolute mate to constrain two Mate Connectors to rotate about their z-axis. Other mates, e.g., Slider, Planar, or Cylindrical, define various relationships between two Mate Connectors. Add offsets and limits, and you have a brilliant, efficient, and flexible system for defining your assemblies.

The fact that Mate Connectors can be used for dozens of non-assembly processes is a subject for another blog.

Versions, Branching, and Merging

Whether it’s CAD or another piece of installed software, teachers are all too familiar with crashes. It was a daily occurrence in my lab. I would announce that the bell was about to ring and that students should save their work. Thirty students would click the save button for the first time all period and at least one student would smash their head into their keyboard in frustration. The program had crashed and they had lost an hour’s worth of work.

With Onshape, every click, drag, edit, and change is automatically saved in your document’s history. Forever. The most obvious benefit of this system is that students can never lose their work. If their neighbor kicks the power cord out of their computer, they can open their document on another device (even their phone) and keep working. Clearly, time savings is a theme here!

When students reach significant milestones in their designs, with file-based systems, their habit is to click “Save As…” and create copies of their work. As most teachers have witnessed, students eventually end up with folders full of files called “Part 1 (2) final final FINAL version 7 GRADE THIS ONE.” With Onshape, there is no need to ever create copies of documents to save work. Instead, click the “create version” button to create a permanent snapshot of your work right in the document’s history.

Versioning also enables another amazing workflow called branching and merging. In an Onshape document, if students ever want to explore divergent or risky design ideas, they can branch their workspace and Onshape will keep track of every change in the branch separate from the main workspace. Multiple branches can even progress in parallel. At any point, design changes in one branch can be merged into another. This workflow encourages brainstorming and creativity in a way that is impossible with file-based systems.

Collaboration

Properly preparing students to be future designers and engineers means teaching them to work together in teams. With traditional CAD, collaborating on designs is cumbersome at best. Only one student can be working on a file at a time and sharing documents requires them to be sent back and forth via email or portable drive. In my lab, a daily frustration was a student taking files home to work on and forgetting to bring them back to school. Or a team’s files would be inaccessible because they resided on the computer of a student who was absent.

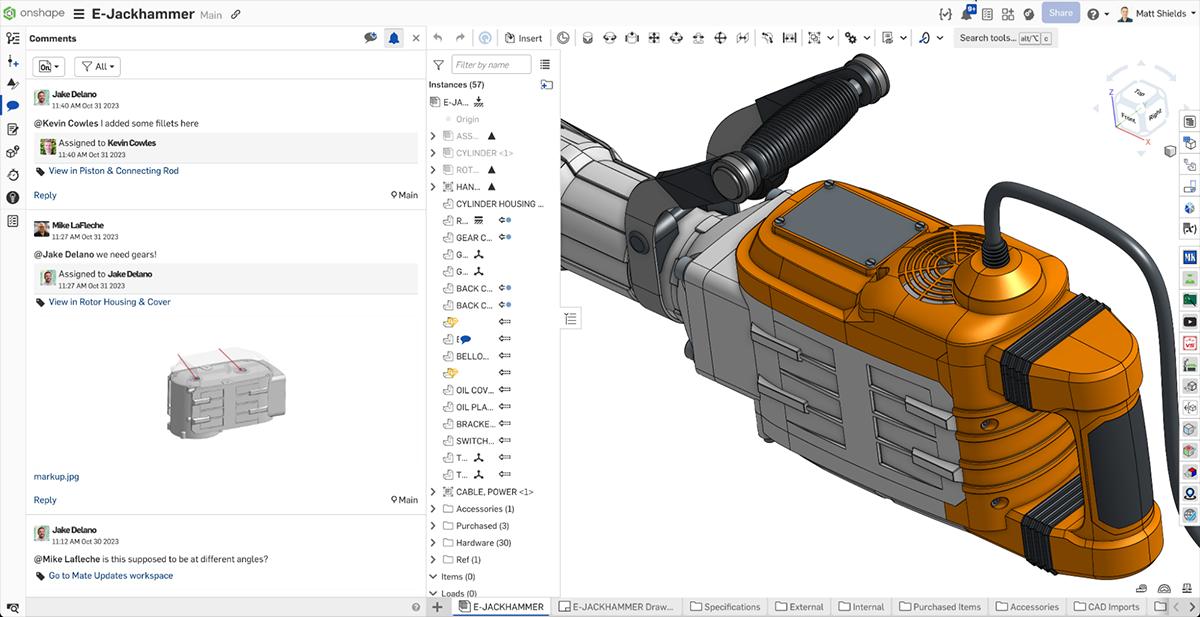

Sometimes called the “Google docs of CAD,” Onshape makes collaboration seamless, intuitive, and fun. With the click of a mouse, students can share documents with as many team members as they desire. Multiple students can work on designs simultaneously, even while working remotely, and everyone is always accessing the most up-to-date CAD data. My students naturally took advantage of the comment thread built into every Onshape document, leaving annotated screen shots for each other and assigning tasks for their teammates. Coupled with the version history, document comments provide a rich history of students’ collaborative processes.

Configurations

Most CAD systems have a system for creating libraries of parts that all derive from a common model, often called configurations. I used to save this topic for my second-year engineering courses because it was difficult to understand and implement.

When I learned how Onshape had reinvented configurations, I made it one of the first lessons in my engineering curriculum. The process for creating configurations in Onshape is so powerful and intuitive that it changes how students create their designs.

In Onshape, nearly any aspect of a design – part dimensions, pattern number, feature suppression state, extrude termination, mirror plane, you name it – can be configured. The configuration interface could not be more intuitive and configurations could not be easier to implement. Teaching the concept of configurations early on helped my students learn design best practices and create more complex and robust designs.

Make Your Classroom an Onshape Classroom

Switching CAD systems can be intimidating, especially if you have already invested in developing curriculum for your current system. I hope my experience encourages you to give Onshape a try. Your students will thank you.

Get Started with Onshape Education

Onshape for Education brings CAD out of the computer lab and into the modern era.

Latest Content

- Case Study

- Consumer Products

BOA Technology: Redefining Outdoor Fit Equipment with Cloud-Native Onshape

11.03.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more