03:42

This article was developed alongside PTC’s Onshape team. It highlights how cloud-native CAD enables the rapid iteration of complex mechanical and robotic systems for sustainable technology.

“Food waste is responsible for 8% of global greenhouse gas emissions, and when you manage food waste with insects, you radically reduce its impact on the world,” said Olympia Yarger, CEO and founder of Goterra, an Australian-based climate startup.

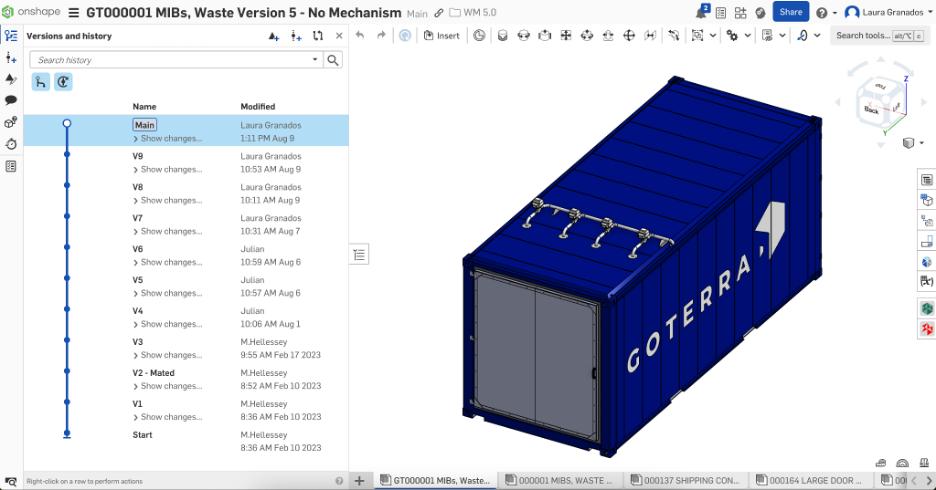

Goterra’s MIBs (Modular Infrastructure for Biological Services), created and led by Yarger, employs innovative technology with robotics to manage food waste onsite with black soldier fly larvae. The system is optimized so the larvae can devour vast amounts of food waste, reducing it by 95% in just 24 hours.

“Using larvae in tandem with industrial robotics means we manage waste efficiently, at the source of creation, producing a sustainable protein that can be used in agricultural supply chains, creating a truly circular system,” said Yarger.

Australia’s First Carbon-Neutral Precinct

In 2020, Goterra developed and commissioned the first commercial onsite MIB at Sydney’s International Towers in Barangaroo in partnership with Lendlease, a multinational construction and real estate company. Barangaroo is Australia’s first mixed-use precinct to be certified as carbon neutral under the government program Climate Active, which incentivizes voluntary climate action.

Goterra's MIB technology offers a flexible deployment model, similar to solar panels that can be installed at homes or aggregated into large solar farms. The standard MIB unit processes over 7 tons of waste weekly through an advanced waste management system.

The process begins with food waste collection and processing through an external holding tank equipped with a hopper, macerator, and RFID scanning system. This system tracks client interactions and precisely measures waste inputs. The macerator converts the waste into a uniform substrate suitable for the larvae.

Inside the unit, an advanced racking system houses millions of black soldier fly larvae. Environmental sensors continuously monitor conditions and insect health, while robotic systems automate feeding and movement. For larger operations, multiple MIB units can be stacked and connected to a central waste hopper.

Goterra maintains the system through regular 10-12 day service cycles, where mature larvae and frass are collected and new larvae are introduced. The harvested materials are transported to Goterra hubs for processing into agricultural products – the larvae become protein feed, while the frass serves as an organic soil conditioner.

Modeling the Maggot Math in Onshape’s Cloud-Native CAD

Onshape’s cloud-native CAD platform has been instrumental in Goterra’s agile development strategy, including Goterra’s MIB deployed at International Towers in Barangaroo. The Goterra team chose Onshape for a variety of reasons.

Collaboration and Productivity

Onshape’s browser-based software has increased collaboration between designers, technicians, and reviewers, resulting in design review and release cycle reduction from 1-2 weeks to 1-2 days. Onshape allows quick design and quick feedback for a faster time to market.

Quality

Product quality is managed through a seamless review and release process. Technicians and reviewers are able to view, measure, and comment parts making it easier to manage quality.

Workflow

Managing development projects in a single document rather than files and folders improves the design phase workflow with automatic updates as parts are changed in real time.

Features We Love

- Mates: It is easy to modify mates between parts just by identifying the mate connector on screen.

- Constraints: A part can be constrained just with one mate.

- Subassemblies: It is easy and smooth to create subassemblies within the assembly and manipulate them.

- Assembly Environment: Superior workspace for managing complex mechanical integrations

The platform's capabilities have proven essential for developing Goterra's robotic systems and racking infrastructure.

Goterra Tackles Food Waste Management

Goterra’s innovative approach to food waste management represents a significant advancement in sustainable technology.

By combining robotic automation, biological processes, and cloud-based design tools like Onshape, Goterra is not just managing waste – it’s transforming it into a valuable resource while addressing critical environmental challenges.

The Onshape Startup Program

Equip your team with full-featured CAD, built-in PDM, and analytics in one system.

Latest Content

- Case Study

- Automotive & Transportation

Zero Crashes, Limitless Collaboration, One Connected Workflow With Cloud-Native Onshape

12.04.2025 learn more

- Blog

- Becoming an Expert

- Assemblies

- Simulation

Mastering Kinematics: A Deeper Dive into Onshape Assemblies, Mates, and Simulation

12.11.2025 learn more

- Blog

- Evaluating Onshape

- Learning Center

AI in CAD: How Onshape Makes Intelligence Part of Your Daily Workflow

12.10.2025 learn more

- Blog

- Evaluating Onshape

- Assemblies

- Drawings

- Features

- Parts

- Sketches

- Branching & Merging

- Release Management

- Documents

- Collaboration

Onshape Explained: 17 Features That Define Cloud-Native CAD

12.05.2025 learn more