06:07

Food-tech companies aim to improve how food is grown, prepared, and delivered to consumers. Using robotics and other automated technologies, teams want to make a difference but know the proof will have to be in the pudding. It’s one thing for a robot to pick mushrooms on a farm or an automated kiosk to make a smoothie, but it’s another thing for the consumer to enjoy the product.

The tricky balance between efficiency and satisfaction is what these companies sought: a cloud-native CAD platform with built-in PDM that would enable them to design quickly, collaboratively, and confidently.

They believe they found it with Onshape, PTC’s cloud-native product development platform. By taking advantage of either the Onshape Startup or Onshape Discovery programs — or simply coming aboard with Onshape Professional — the startups are no longer worried about lost or siloed design files, or worse. With Onshape, CAD has never tasted or smelled as good.

“Onshape is something I don't need to worry about, whether I'm on a laptop or desktop,” said

Roman Kozak, co-founder and CTO of the agriculture-tech platform Verdi. “I know it’s going to work, and the things Onshape does well are the things we need to do 95 percent of the time.”

CAD Task Management Supports 4AG Robotics’ Bold Ambitions

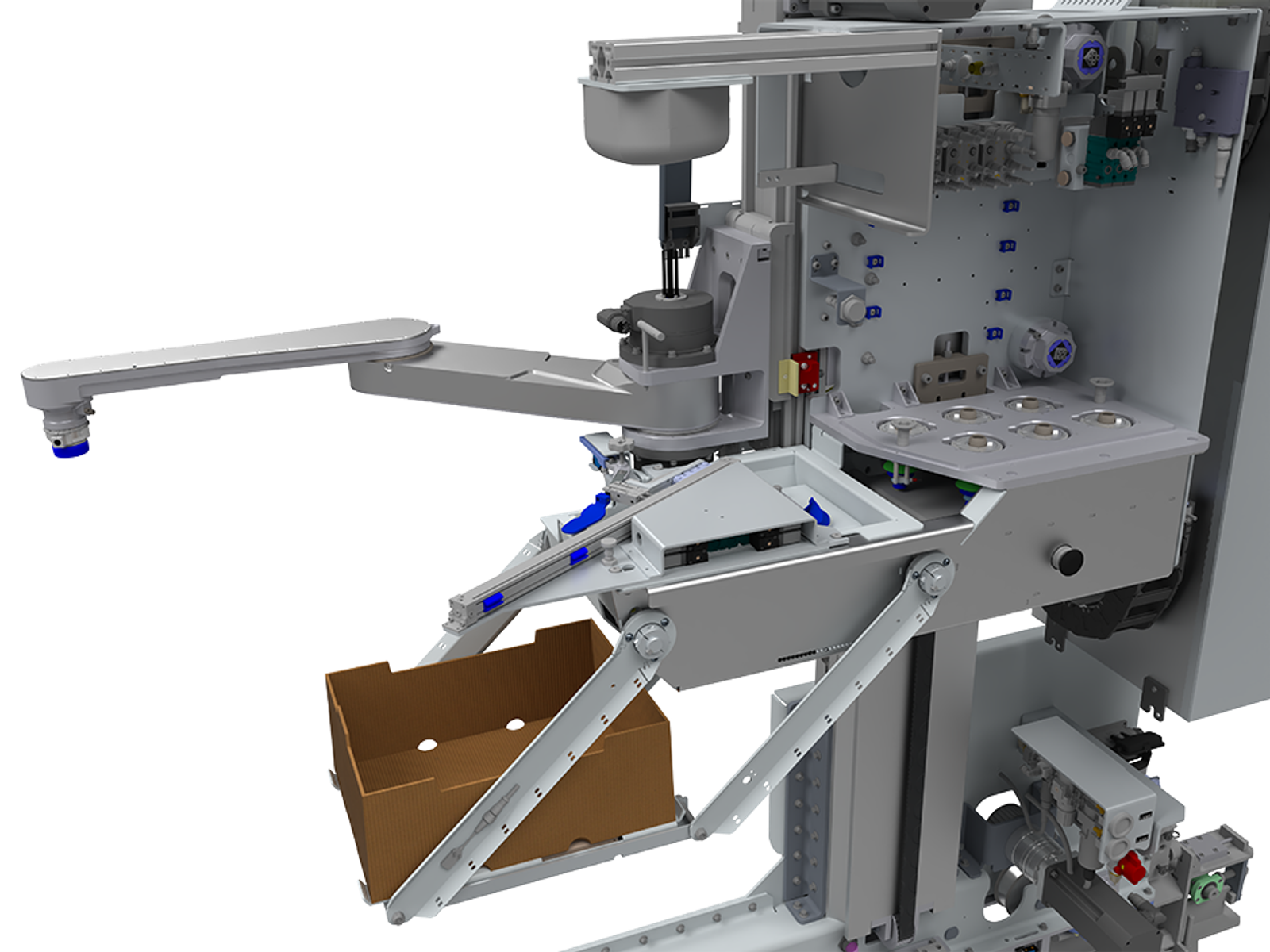

4AG Robotics sees an opportunity to automate the labor-intensive, back-aching process of mushroom picking. The Canada-based company creates vision-guided robots that can move along the shelves of a farm’s interior mushroom beds and pick the harvest. Its mechanical team migrated to Onshape Professional and quickly recognized the cloud-native PDM platform would support the scaling up of product and development design.

The team sees more farms turning to robotic pickers because of a shortage of human laborers, so they’re happy Onshape — particularly its built-in task management — will help them meet that demand.

“We wanted a single place for our mechanical team and design team to focus their efforts,” said James Gibson, the mechanical team lead at 4AG Robotics. “With Onshape, there will be data sheets for files that can all be saved and versioned. We can find all of our CAD, all of our action items, and all the priorities for them. We look at this as a central place to work from and not have to be jumping around. You don’t have to remember where everything is.”

Accessible Workspaces Multiply Precision-Picking Robots

4AG Robotics isn’t the only startup automating farm work. Muddy Machines also has a precision-picking robot that its employees believe will transform farming from a human-dependent endeavor to a more productive, cost-saving enterprise.

According to company Vehicle Design Engineer James Fraser, farmers in the U.K. are already benefiting from automated asparagus picking because of its robot Sprout.

“Our key mission is to make agriculture better for people and better for the planet,” he said.

Muddy Machines has been able to put aside its many frustrations with SOLIDWORKS and instead take advantage of Onshape’s cloud-CAD features — including the duplication of a workspace without compromising the original, branching that always saves work, and the mobile device app that allows Fraser’s team to compare design needs with farming realities on the ground.

“We are starting to go from a small number of robots to thinking about how we’re going to make the next hundred,” Fraser said. “There are going to be challenges that we will need to solve in the design, but we’re happy we’ll be doing that with Onshape.”

Verdi is Changing Ag Irrigation, One CAD Design at a Time

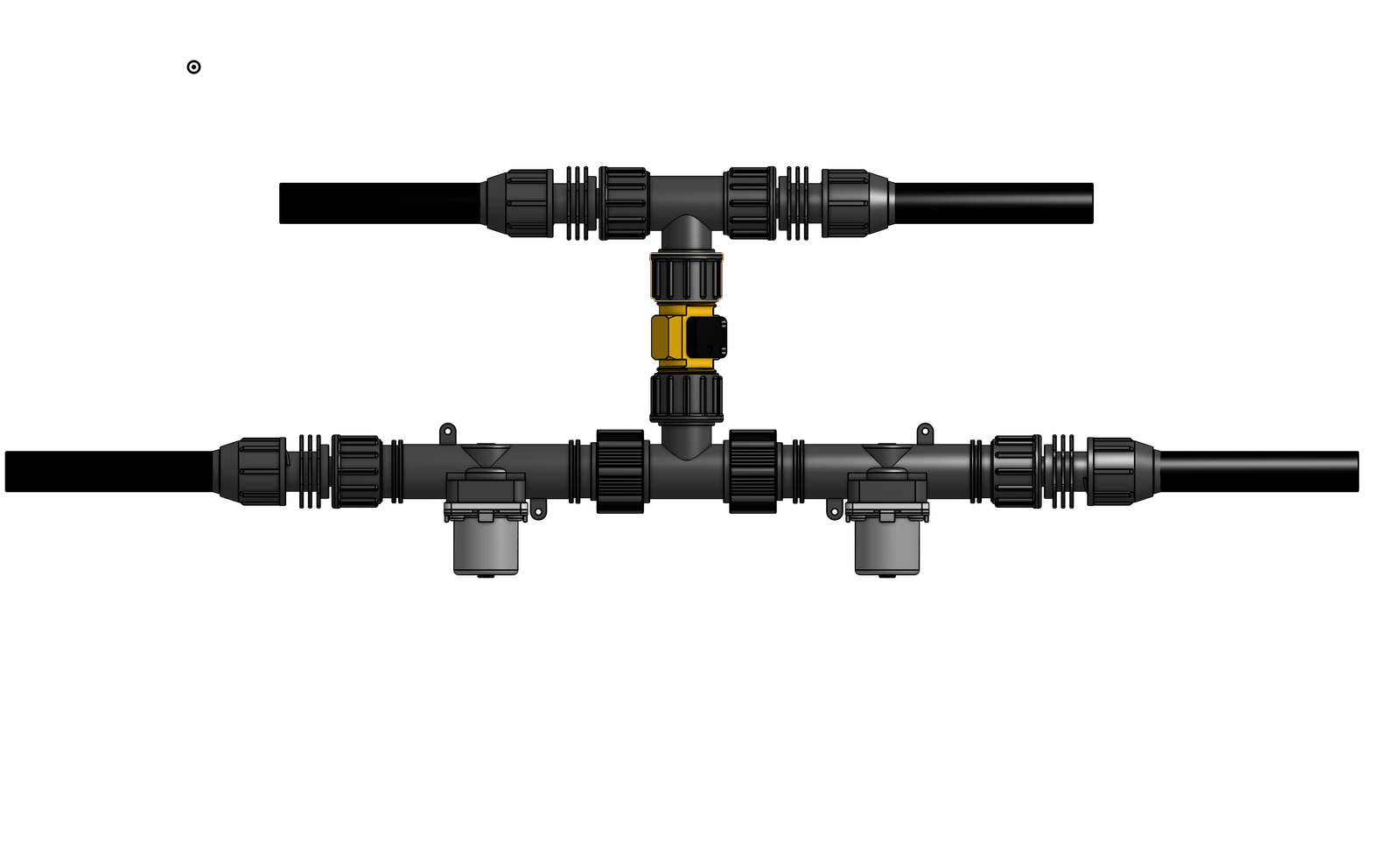

Storms, droughts, drastic soil differences, and many other factors can frustrate the most diligent of farmers. Canada-based Verdi has a solution that even Old MacDonald would have savored on his farm: a technology platform that helps irrigation be more predictable. The platform lets farmers consider the weather, soil differences, and other factors as they control water and fertilizer on a more accurate and granular scale, rather than the longstanding approach of irrigating all plants at the same time and with the same amount of water.

To start scaling its business, Verdi transitioned to Onshape through its Startup Program. Kozak, the CTO, appreciates how simple it is for his team to collaborate.

One of those teammates, mechanical engineer Simon Fu, said that collaboration has allowed constructive feedback before a product prototype is finalized.

“We will have a couple of different concepts, and we can compare and evaluate them against each other in a variety of different ways,” he said. “The ability to easily pull up and share designs during that stage is very important.”

Fellow’s Cup is Filled by the Many Advantages of SaaS CAD

There are many coffee and espresso machines on the market. A coffee enthusiast might need to sit down with a hot brew just to get a handle on it all.

Nicholas Terzulli, vice president of research and development at California-based Fellow Products, believes his company’s coffee products surpass the crowd with their functionality and aesthetics. They look and work great, he says. He would know, as his team spends a lot of time designing and testing high-end coffee makers, grinders, and other products.

That’s why Terzulli convinced his company to invest in Onshape Professional if the team wanted to see results from the development.

With Onshape PDM, “everything is there just to let you do the work you want to do,” he said. That means timely platform updates, the ability to pick up work on any electronic device, and not having to worry about saving work.

“I like the software-as-a-service aspect of Onshape, where you don’t have to get locked into certain things or pay hefty licensing fees to get what you need.”

Designing Zenblen Kiosks with Cloud CAD, a Smoothie Process

An office snack machine is a popular destination from after lunch until quitting time. The machines, though, rarely offer healthy food and drinks. The people of Zenblen hear your body’s cries for nutrition. The Chicago startup creates automated kiosks that prepare smoothies made of fruits, vegetables, and nut milk. The kiosks blend the ingredients before the watchful eyes of a customer before dropping the cup for the first sip.

As Zenblen Lead Engineer Dan Bernacki likes to point out, what looks like magic to the consumer requires complicated engineering — from making the machine understand touchscreen prompts to mixing the ideal smoothie.

Unable to afford SOLIDWORKS, Zenblen’s relationship with Onshape opened the door to the Startup Program. The cloud CAD and PDM package of Onshape Professional has helped Bernacki’s team easily mate kiosk parts in assemblies.

“Onshape helps us see how the different systems integrate with each other,” Bernacki said. “Because it’s fast and has tools that can position the different rotary axes, we’re able to have a lot of insight on how things work together.”

As engineers and developers told us when they took time away from their game-changing food-tech inventions, Bernacki said he couldn’t envision Zenblen advancing without Onshape.

“What we're going for is a healthy option that’s available 24/7 for consumers,” he said. “The kiosk is the vehicle for delivering that, so we have to get it right. I’m happy with the decision we made and looking forward to continuing to work with Onshape.”

Try Onshape Today

Head to our sign-up page to choose the right CAD plan for you and your team.

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more