07:55

Every year, the Onshape team gathers for a spirited showcase of creativity, engineering, and collaboration: the annual (internal) Onshape Design Competition. This year’s entries pushed boundaries across modeling, simulation, scripting, and physical computing.

Among the standouts? The Keyboard Warriors Team’s split ergonomic keyboard, where the new Mirror Assembly became the secret weapon for creating perfectly symmetrical halves with configurable precision.

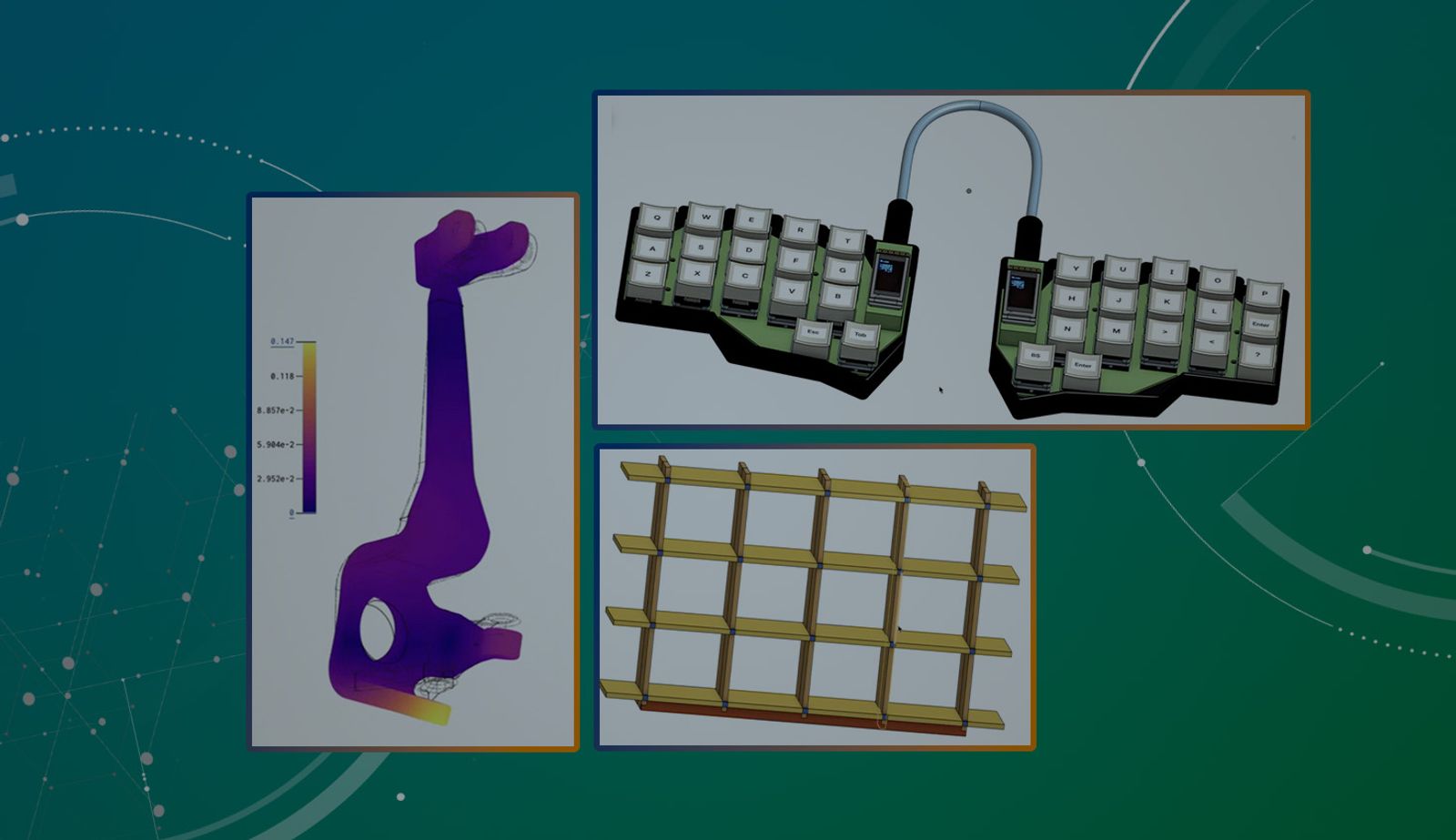

And in the Simulation category, Inertial Relief took center stage, enabling fixtureless stress analysis that revealed structural insights impossible with traditional constraints.

Let’s dive into the highlights and celebrate the ingenuity behind each submission.

Competition Themes: Innovation in Action

This year’s competition revealed two standout techniques that elevated multiple entries: Mirror Assembly for symmetrical designs and inertial relief for advanced simulation. Mirror assembly allowed teams like the Keyboard Warriors to replicate components symmetrically across an axis – reducing errors and speeding iteration.

Meanwhile, Inertial Relief enabled fixtureless simulations, as demonstrated with the steering knuckle analysis entry.

Together, these tools showcase how Onshape empowers designers to work smarter, not harder.

Competition Showcase Highlights

Code It: Braille Translator

Tools: 3D Printing, FeatureScript, Sketching, Boolean Operations

Onshape Senior Software Engineer Nathanael Mathieu brought accessibility to the forefront with his Braille Translator. Inspired by a roommate who is visually impaired, Nathanael created a FeatureScript that converts single words into Braille geometry for 3D printing. The project enables tactile identifiers for board game components like One Night Werewolf, transforming gameplay into an inclusive experience.

“My roommate is visually impaired and he loves playing board games, but that’s often very challenging for him,” Nathanael explained during his presentation.

The feature adheres to strict Braille specifications for dot size and configuration, making the translation geometrically accurate and printable. While currently limited to single words, the tool represents an elegant blend of empathy and engineering – proving that CAD can solve real-world challenges through inclusive design.

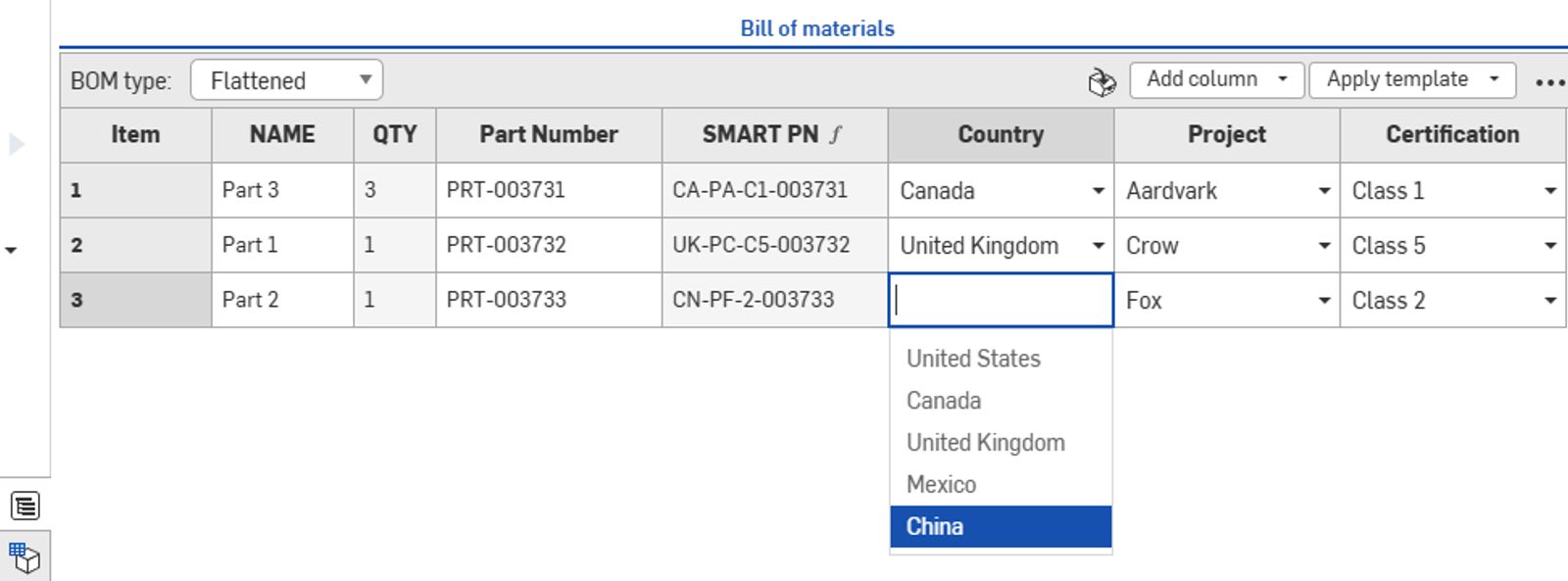

Code It: Smart Part Numbers

Tools: FeatureScript, Custom Properties

Onshape Senior Technical Services Engineer Kevin Cowles demonstrated how automation can streamline workflows with Smart Part Numbers. By leveraging Onshape’s custom properties, Kevin built a Computed Property that dynamically generates part numbers based on country, project, and certification inputs, eliminating manual entry errors and enhancing efficiency across teams.

“A lot of the time we get questions about how Onshape can handle part numbers based on different categories and projects,” Kevin explained. “Rather than having to create some complicated API extension, Onshape can actually handle that with a custom property.”

TECH TIP: Creating an Alias List with Computed Properties in Onshape

His solution reads subcategories like country codes, project identifiers, and certification types to automatically generate intelligent part numbers that sit alongside Onshape’s native part numbering system.

Assemble It Judges' Choice Winner: Onshape Race Car

In the “Assemble It” category, returning intern Luciano Nargang modeled a race car inspired by the Dallara DW12 chassis used in the Indy 500. His project pushed the boundaries of native Onshape modeling, especially in surfacing techniques.

“I’m from Indianapolis, Indiana…the racing capital of the world. We take it fairly seriously over there,” Luciano said.

After the Indy 500 before his summer internship in Boston, building a race car felt like the natural next step. The model showcased his evolution from solid, sketch-defined designs to smoothly surfaced, complex shapes – all modeled natively in Onshape without imports. His work is a prime example of how personal interests can fuel technical growth and design exploration.

Model It Judges' Choice Winner: Shelf Wizard

Tools: Variable Studio, Render Studio

Onshape Software Development Engineer Benjamin Corey tackled practical design challenges with Shelf Wizard, a configurable shelving system built using Variable Studio. His model allows users to adjust dimensions and generate subcomponents for custom assemblies – then actually build them in a woodshop.

“I decided I wanted to build a shelf to go under the overhang on my kitchen island,” Ben explained. “I might as well try to design it properly in Onshape and see what we get there.”

The parametric system produces manufacturable parts complete with joinery details, designed for table saws and typical woodworking tools. Ben shared insights from the build process, including adapting cut depths when his table saw could only handle two-inch depths instead of the modeled 2.5 inches.

His parametric modeling approach allowed for rapid iteration between digital design and physical prototyping. Ben also explored Render Studio to visualize the finished product, demonstrating how Onshape supports the entire workflow from concept to fabrication.

Simulate It Judges' Choice Winner: Steering Knuckle

Tools: Inertial Relief, von Mises stress analysis, Simulation

In the “Simulate It” category, intern Kyle Tennison applied Onshape’s inertial relief feature to analyze stress on a steering knuckle under extreme conditions. His simulation accounted for forces from suspension, steering, and vehicle weight – such as those experienced during cornering or curb impacts.

“These things are exposed to quite a few different loads,” Kyle said. “If you’re in a pretty intense scenario – say you’re cornering while coming off a jump and then also hitting a curb – you can imagine how things can start to break.”

His loading scenario included 7,000 pounds of force from the lower control arm, tie rod forces during hard steering, and dynamic wheel loads four times the static weight.

The key innovation? Using inertial relief to create a fixtureless simulation.

“In most FEA software, you need to fix a face or a part,” Kyle explained. “But if there's no good place to fix your model without getting unrealistic results, you can use inertial relief.”

The analysis confirmed a safety factor above 1 across the entire component, validating the design's structural integrity while revealing areas where a performance-focused design might optimize for weight reduction.

Best Overall – Just Do It: Tapemeister 404

Tools: 3D Printing, ECAD, Python, Raspberry Pi

Onshape Senior Technical Services Engineer David Nguyen combined hardware and software in Tapemeister 404, a Raspberry Pi-powered RFID music player. The device uses RFID cards to trigger MP3 playback, with each card linked to a song via a JSON file.

He integrated 3D printing, electronics, and Python scripting to build the enclosure and control logic, using in-context design to fit the Raspberry Pi Zero, audio board, battery management system, and RFID reader into a child-friendly enclosure.

David discussed challenges like implementing safe shutdown protocols to prevent SD card corruption and achieving multicolor prints with his new filament system. He credited AI tools like Gemini for debugging support:

“I’m not a programmer at all,” he said. “AI really brought me to the next level…it creates something working for me in the end.”

The project showcased iteration through physical prototyping, with multiple printed versions refining the form, fit, and function.

Just Do It Judges' Choice Winner & People's Choice: Split Ergonomic Keyboard

Tools: PCB Design, Branching and Merging, Mirror Assembly, Configurations, Decals

The Keyboard Warriors Team closed the showcase with a collaborative ergonomic keyboard design. Using Onshape’s branching and merging features, the team developed a split keyboard with an ortholinear layout that promotes natural hand positioning and reduces strain.

“This is a split keyboard designed to be more ergonomic for your hands,” a team member explained. “The layout is ortholinear, which means if you have your ring finger and you want to go from W to S, you only have to move it straight up. Whereas on a QWERTY keyboard you have to go up and a little to the left. This reduces travel distance and should reduce carpal tunnel.”

The mirror assembly feature proved essential for creating symmetrical halves, while configurable decals and realistic switch modeling added polish and precision.

The team leveraged Onshape’s collaborative tools to divide work across components: “We could split the entire assembly into different components and each of us could work on each component differently, then seamlessly merge it back together.”

The result? A detailed, functional design with intricate switches modeled from technical drawings, all brought together through effective version control and teamwork.

Building Something Meaningful

From Braille translators to race car models, steering knuckle simulations to music players, this year’s entries reflect the creativity and technical depth of the Onshape team. Interns, developers, and designers alike pushed the platform’s boundaries – and each other – to build something meaningful.

Ready to try Mirror Assembly or Inertial Relief yourself? Open Onshape, start a new assembly, and explore how symmetry can simplify your next design.

The Onshape Discovery Program

Learn how qualified CAD professionals can get Onshape Professional for up to 6 months – at no cost!

Latest Content

- Case Study

- Robotics

Saga Robotics: Powering the Future of Sustainable Farming with Cloud-Native Onshape

01.05.2026 learn more

- Blog

- Evaluating Onshape

- Simulation

- Rendering

- Surfacing

- Consumer Products

Earlier Validation, Better Outcomes: Onshape’s Approach to Surface Design

02.20.2026 learn more

- Blog

- News from Onshape @ PTC

- Publications

- Configurations

- Data Management

Onshape MBD: Single Source of Truth from Design to Manufacturing and QA

02.23.2026 learn more

- Blog

- Becoming an Expert

- Sheet Metal

Two Views, One Model: Faster Sheet Metal Design in Onshape

02.12.2026 learn more